Brett James-McCall

Moderator

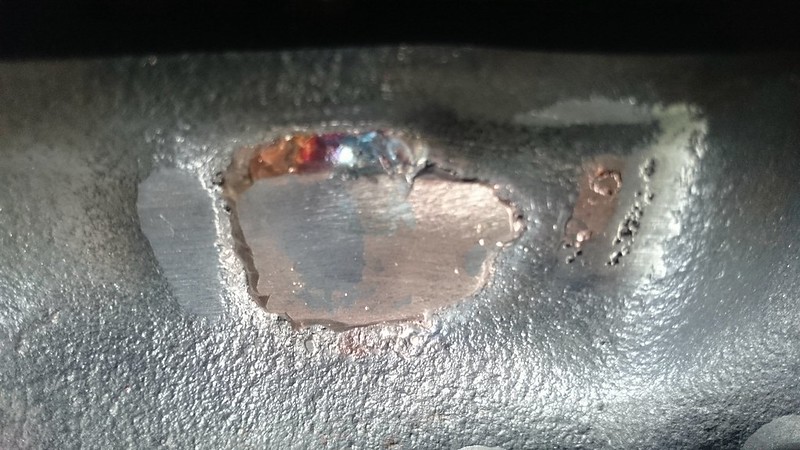

So I have messed up big time this morning :cry:

I was drilling the new coolant holes in the block to match the heads and have managed to misalign slightly and have drilled through into the oil gallery.

Can I weld or similar over the top of this, as it is only between the coolant passage and the gallery?

Any help appreciated. Thanks

I was drilling the new coolant holes in the block to match the heads and have managed to misalign slightly and have drilled through into the oil gallery.

Can I weld or similar over the top of this, as it is only between the coolant passage and the gallery?

Any help appreciated. Thanks