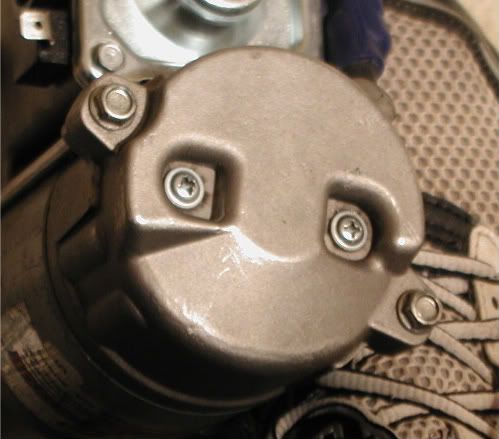

As the saying goes,,,, if it can go wrong it probably will go wrong. I am now in the market for a starter for my 930. What is the consensus?? I had the Hi Torque starter. I chose it because it had a clockable face and allowed me to put the starter in without altering frame members. Well at my final tune up yesterday(second time for this actually) the starter started making some funny sounds. We observed the same grinding sound and intermittent action that happened when it tore up the ring gear(this will be the third time in 3 months if it did it again). When we used the starter without the ignition key on, it turned the engine consistantly without all the calamity. Later on we saw sparks flying out the back of the unit at two screw mounts. The volt meter was jumping wildly from 14 volts to 10 volts also. We surmised also that the starter just wasn't turning the engine over fast enough to trigger the starting function of the ignition system, or it was acting intermittently. Maybe 300 rpm of so. As most of you know I am running the 351 Wiindsor bored and stroked to 396 with AFR 205 heads with flat top pistons, so the c.r. is not high. We called the session off. I haven't pulled the starter yet as I am fairly depresed over this new(rather old really) problem. Had this acted as it should I would be out there drving the car as we speak.

What I am looking for is SPECIFIC starters. If porsche, I need the model that will work best. There are several refubished units on Ebay.

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-53></TD></TR></TBODY></TABLE>

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-53></TD></TR></TBODY></TABLE>

Porsche 944 Turbo S2 - Starter

Porsche 924 944 Bosch Starter SR39

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=v4-50 class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD class=vi-ia-attrColPadding width="50%" headers=v4-50></TD></TR><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-51></TD><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-52></TD></TR></TBODY></TABLE>Mfg Pt. # 0-001-108-021

Interchange #SR39x, 17023

Poster sells alternators and starters of all types

Porsche 911 High Torque Bosch Starter SR68X

Mfg.#R68X

Interchange #001312110, 6986012660, 91160410101

Porsche 924 Bosch Starter 1986 1987 1988 2.5L 944 1986 1991 2.5L 2.7L and 3.0L

Mfg.# SR39x

Interchange # 0-001-108-021

Auto electric co.

Other starters by this seller are:

Porsche Starter 944 1986 1987 1988 89 1990 1991 2.7L 3....

911 930 Porsche NEW STARTER 1966 68 70 72 74 76 77 80 8...

Pt. #911-604-101-01

Porsche 911 930 NEW HD STARTER 1966 67 68 70 71 73 75 7...

Pt.#0-001-312-100 also SR 68x

PORSCHE 911 BOXSTER NEW STARTER 1997 1998 1999 2001 200...

Pt.#996-604-104-00 SR0430x

This guy has almost every Porsche starter there is.

High Torque Starter for Porsche 911SC (1978-1983)

This one is a new unit that apears to be the same as I have. All the others are referbed or reconditioned units

So lets hear what you guys are using. Lord knows my choices(or luck) have been awful.

Bill

What I am looking for is SPECIFIC starters. If porsche, I need the model that will work best. There are several refubished units on Ebay.

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-53></TD></TR></TBODY></TABLE>

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-53></TD></TR></TBODY></TABLE>

Porsche 944 Turbo S2 - Starter

Porsche 924 944 Bosch Starter SR39

<TABLE cellSpacing=0 cellPadding=0 width="100%"><TBODY><TR><TH id=v4-50 class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD class=vi-ia-attrColPadding width="50%" headers=v4-50></TD></TR><TR><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-51></TD><TH id=vi-ia-attrSectionLastRowTd class="vi-ia-hdAl vi-ia-attrLabel vi-ia-attrColPadding" noWrap align=left></TH><TD id=vi-ia-attrSectionLastRowTd class=vi-ia-attrColPadding width="50%" headers=v4-52></TD></TR></TBODY></TABLE>Mfg Pt. # 0-001-108-021

Interchange #SR39x, 17023

Poster sells alternators and starters of all types

Porsche 911 High Torque Bosch Starter SR68X

Mfg.#R68X

Interchange #001312110, 6986012660, 91160410101

Porsche 924 Bosch Starter 1986 1987 1988 2.5L 944 1986 1991 2.5L 2.7L and 3.0L

Mfg.# SR39x

Interchange # 0-001-108-021

Auto electric co.

Other starters by this seller are:

Porsche Starter 944 1986 1987 1988 89 1990 1991 2.7L 3....

911 930 Porsche NEW STARTER 1966 68 70 72 74 76 77 80 8...

Pt. #911-604-101-01

Porsche 911 930 NEW HD STARTER 1966 67 68 70 71 73 75 7...

Pt.#0-001-312-100 also SR 68x

PORSCHE 911 BOXSTER NEW STARTER 1997 1998 1999 2001 200...

Pt.#996-604-104-00 SR0430x

This guy has almost every Porsche starter there is.

High Torque Starter for Porsche 911SC (1978-1983)

This one is a new unit that apears to be the same as I have. All the others are referbed or reconditioned units

So lets hear what you guys are using. Lord knows my choices(or luck) have been awful.

Bill