I'm interested in knowing how many of you running EFI have an inertia switch on the high pressure fuel pump, what type you used and where you mounted it. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EFI fuel pump inertia switch

- Thread starter daryl adams

- Start date

Daryl,

I use one but it cuts the power to both fuel pumps. You need both. The true name of these switches is rollover switch. It also works in an impact as well. I mounted mine in the cabin on the center console in plain view. I have had mine trigger just form working in the cabin, but never just driving around. I use this type.

Painless Performance Products 80160 Painless Replacement Switches & Kits

Talking about safety I also have a low oil pressure switch that cuts the fuel pumps when pressure is less than 5psi. Can't always be looking at the gauges and it will save an engine$$$$$. To aid in starting I have a bypass switch that will allow the engine to start easier rather than just letting it spin til pressure builds.

Bill

I use one but it cuts the power to both fuel pumps. You need both. The true name of these switches is rollover switch. It also works in an impact as well. I mounted mine in the cabin on the center console in plain view. I have had mine trigger just form working in the cabin, but never just driving around. I use this type.

Painless Performance Products 80160 Painless Replacement Switches & Kits

Talking about safety I also have a low oil pressure switch that cuts the fuel pumps when pressure is less than 5psi. Can't always be looking at the gauges and it will save an engine$$$$$. To aid in starting I have a bypass switch that will allow the engine to start easier rather than just letting it spin til pressure builds.

Bill

I'm interested in knowing how many of you running EFI have an inertia switch on the high pressure fuel pump, what type you used and where you mounted it. Thanks.

Daryl,

See Bill's post. I have exactly what he's linking to in the Pantera and the GT40. I think I got mine from Pegasus though or maybe JEGS or maybe Summit... Probably Pegasus.

:laugh:

Regards,

Kirby

Tom,

When the fuel line ruptures it will empty fast enough on its own!!

Bill

When the fuel line ruptures it will empty fast enough on its own!!

Bill

I use them and moreso with the GT-40.

However, with the fuel pump shutting off immediately after an impact, there is still close to 60psi in my EFI stack system. I'd like to figure out how to dump that pressure quickly in case a fuel line ruptures on the pressure side.

It would be neat to have something like this that would be a normally open 3-way valve which (when energized) would route the fuel straight through to the rail supply and when contact is broken would vent the rail supply to the return line to the tank. But the complexity of a system like that may outweigh the benefits since the overall volume of fuel that would be vented would be minimal.

Good thinking though!

Tom,

When the fuel line ruptures it will empty fast enough on its own!!

Bill

Yeah, all over my red hot headers or shorted battery, cuz I'm going out in a blaze of glory! LOL

Randy is correct. If you guys remember your physics lessons in high school, You will remember that fluids are not compressable like air. Once you remove the pressure on the liquid, its volume change is negligable. Put another way, about a drop if that much. Then again, a drop is all you need for a fire/explosion!!!

The only way you would get any more than that is if the tubing were stretched and it rebounded when the pressure was released. If you have braided steel lines that couldnot be very much. The real problem is the fuel IN the line and IN the swirl tank. If you are upside down, the fuel lines would be lower than the tank and would drain the tank. If upright maybe it would be a good idea for the fuel to run back down into the tank. Just hope the tank isn't ruptured!!

Bill

The only way you would get any more than that is if the tubing were stretched and it rebounded when the pressure was released. If you have braided steel lines that couldnot be very much. The real problem is the fuel IN the line and IN the swirl tank. If you are upside down, the fuel lines would be lower than the tank and would drain the tank. If upright maybe it would be a good idea for the fuel to run back down into the tank. Just hope the tank isn't ruptured!!

Bill

Jack Houpe

GT40s Supporter

Daryl, in most EFI systems when the engine stops the pump stops but I have mine wired differently using the switch on the dash, I plan on redoing this the next time I have the 40 in the garage as when an accident happens your mind doesn't think as quickly as the computer.

Jack,

Using the ECU is a good way to control your pumps from a power standpoint. However you need to control it from an accident standpoint as well. If you roll over or have a shunt your ignition may not be K O'd and your pumps will continue to run. You need the sensitivity of the roll over switch, and the protection from a low oil pressure event regardless of its cause. Think a long high speed turn with a trap door stuck open in the oil pan.

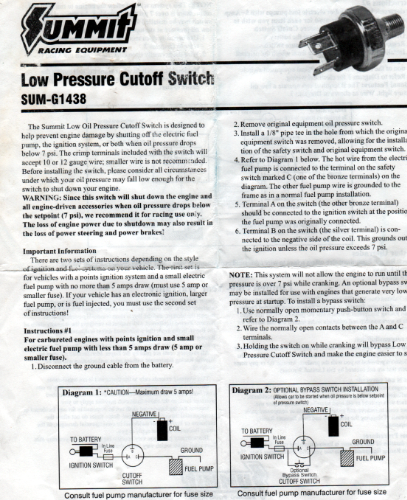

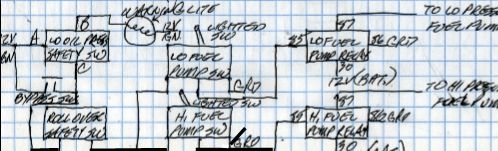

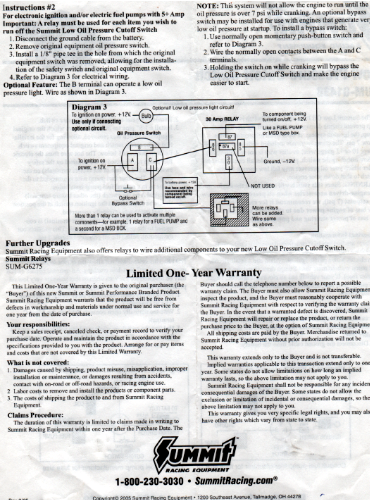

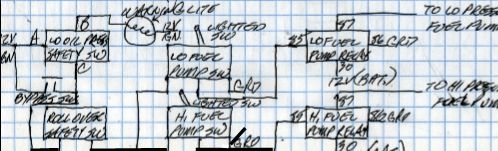

Here is the low oil pressure switch with a carburator

Here with EFI

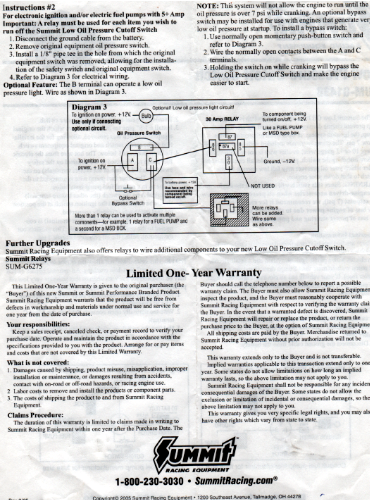

Here it is with the rollover switch and the low oil pressure switch with a lighted dash switch. The roll over switch can be in front of or after the LOPS

Bill

Using the ECU is a good way to control your pumps from a power standpoint. However you need to control it from an accident standpoint as well. If you roll over or have a shunt your ignition may not be K O'd and your pumps will continue to run. You need the sensitivity of the roll over switch, and the protection from a low oil pressure event regardless of its cause. Think a long high speed turn with a trap door stuck open in the oil pan.

Here is the low oil pressure switch with a carburator

Here with EFI

Here it is with the rollover switch and the low oil pressure switch with a lighted dash switch. The roll over switch can be in front of or after the LOPS

Bill

Jack Houpe

GT40s Supporter

Yep Bill thats another thing to add when I change it over. Good protection.

Thanks guys. I've been getting a little spooked about safety lately and the fuel thing is something I want to address. I have a fuel pump switch on the dash, and the easiest thing to do would be to just wire an inertia cutoff before that switch and mount it under the dash. The thing that bothers me is remembering a particularly bad track shunt I saw where a guy spun and got smacked in the rear quarter. It spun him around and started a fire, but because the car essentially rotated around the point where the inertia switch was located, the switch didn't receive enough impact load to trip the circuit. The car just sat there with a broken fuel line spouting 40 psi race fuel like a vertical flame thrower. I'm leaning toward just mounting the thing on the bulkhead behind me, right above the high pressure pump.

Ian Anderson

Lifetime Supporter

External / Marshall Power kill switches would do it too!

Jack Houpe

GT40s Supporter

Inertia switch is obligatory item in these type of cars, i think must use with carbs too.

When you crash and are comatous, main cut off don`t help; main power is on, ignition on, fuel pump on, then it can be BBQ-time...

Can`t use inertia-type in rally cars, and got problems even with one very hard suspension track car; didn`t find adjustable i-switch then. Instead i program fuel pump cut off with 2 sec delay when ecu realize engine don`t run anymore for these. It`s standard equipment for every road car, but not necessarily in kit/race cars. Check yours.

When you crash and are comatous, main cut off don`t help; main power is on, ignition on, fuel pump on, then it can be BBQ-time...

Can`t use inertia-type in rally cars, and got problems even with one very hard suspension track car; didn`t find adjustable i-switch then. Instead i program fuel pump cut off with 2 sec delay when ecu realize engine don`t run anymore for these. It`s standard equipment for every road car, but not necessarily in kit/race cars. Check yours.

Similar threads

- Replies

- 9

- Views

- 758

- Replies

- 4

- Views

- 338

- Replies

- 17

- Views

- 2K

- Replies

- 14

- Views

- 967