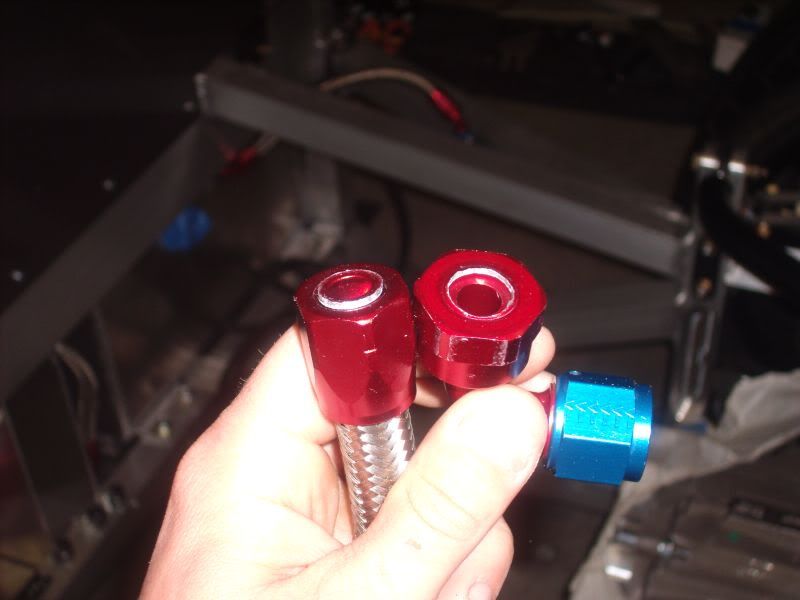

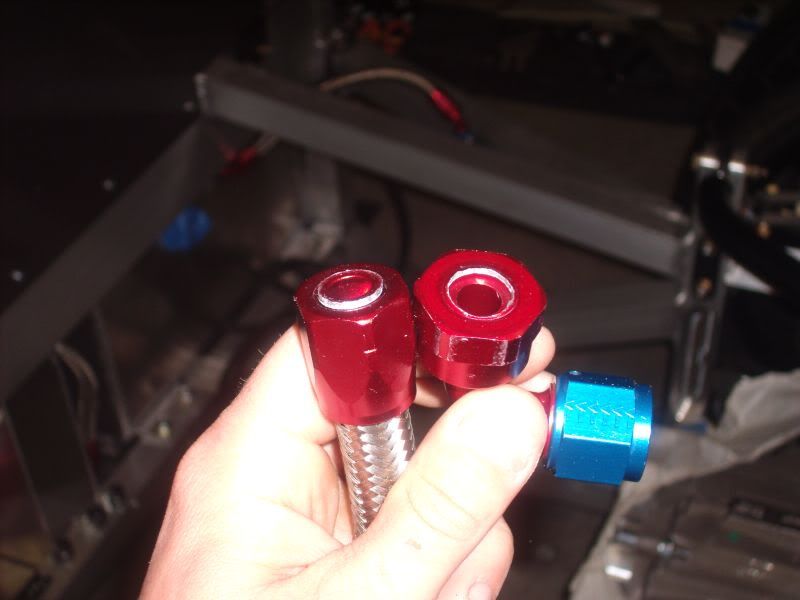

From the inventor of stripped balljoint studs at 50ft-lbs of torque comes...

Sheering Aeroquip fittings :idea:

And no, I didn't use a breaker bar to tighten it - I was still atleast 1 full turn away from minimum seated spec (1/32'') and it just snapped. No warning, no extra resistance or weird noises, just happily turning away, then...snap. Guess there's a first time for everything :shifty:

- I was still atleast 1 full turn away from minimum seated spec (1/32'') and it just snapped. No warning, no extra resistance or weird noises, just happily turning away, then...snap. Guess there's a first time for everything :shifty:

Sheering Aeroquip fittings :idea:

And no, I didn't use a breaker bar to tighten it