You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rev limit for 302?

- Thread starter simonjrwinter

- Start date

Your answer will depend on a lot of things. Stock block? Stud girdle? Valvetrain specifications? Standard rod length and stroke? Forged rods? Forged crank? Forged pistons? Your answer will still be pretty much a guess anyway, but almost certainly less than 7,000 rpm, probably between 6,000 and 6,500 rpm. The stock 302's worst enemies are high revs and detonation. The lower you set the limiter the longer then engine will live.

Ross Nicol

GT40s Supporter

GT40 Guy

The bottom end of the 302 is the limiting factor for max revs.Standard cast crank and 2 bolt main bearing caps limit revs to about 6500. Steel crank and 4 bolt block allows a higher rev limit. Piston size and heads have no bearing on rev limit.

The fact the motor has been balanced is good but make sure the harmonic balancer, crank and flywheel/clutch have been balanced as a unit. If the crank is externally balanced 28oz counter weight for pre 80's 50oz for later HO motor.

regards Ross

The bottom end of the 302 is the limiting factor for max revs.Standard cast crank and 2 bolt main bearing caps limit revs to about 6500. Steel crank and 4 bolt block allows a higher rev limit. Piston size and heads have no bearing on rev limit.

The fact the motor has been balanced is good but make sure the harmonic balancer, crank and flywheel/clutch have been balanced as a unit. If the crank is externally balanced 28oz counter weight for pre 80's 50oz for later HO motor.

regards Ross

The cam is only going to make power in a certain range, so it has a big bearing on your rev limit.

The lifter type (hydraulic or solid) and valve springs have a bearing on the red line as well.

Who built the engine? I would ask the builder what he recommends as a redline. If you built it yourself, you might want to put it on the dyno, as that will give you a pretty good idea of what's going on...

The lifter type (hydraulic or solid) and valve springs have a bearing on the red line as well.

Who built the engine? I would ask the builder what he recommends as a redline. If you built it yourself, you might want to put it on the dyno, as that will give you a pretty good idea of what's going on...

This is interesting for me too because mines on a trackday soon. My 302 is older but standard. I was under the impression that the stock rev limit was 5000, momentarily 5500 rpm. Mine has no guts past 5000 anyway and I can't afford another one just yet so I'm careful. It is written that over revving stretches the timing chain, perhaps some petrol heads in the 'States can shed some light on this? An experienced engine builder should quote figures from memory but this could be difficult as there are many levels of tune...any ideas?

From what I've read, and this topic has

been discussed here before, without good internals and a girdle, I wouldn't push

a 306 (302 bored 30 over) past 6000.

With a girdle, forged crank/rods, correct

cam, and good valvetrain, a 302/306 can

hit 8000 without much concern. The block

is designed to do this.

One of these days I will post some numbers

I have in a few books that show that a 302

turning at 8000 wears less than a 351 at

6500.

Ian

been discussed here before, without good internals and a girdle, I wouldn't push

a 306 (302 bored 30 over) past 6000.

With a girdle, forged crank/rods, correct

cam, and good valvetrain, a 302/306 can

hit 8000 without much concern. The block

is designed to do this.

One of these days I will post some numbers

I have in a few books that show that a 302

turning at 8000 wears less than a 351 at

6500.

Ian

Howard Jones

Supporter

The Guy down the street builds sprint car motors and we were talking about my motor and he said that a streetable cam and valve/ heads combo will more or less make the most thrust at about 5600-5800. He said to set my rev limiter at 5800 and it will run forever in that car of yours. My motor is a 345HP 302 crate motor from SVO with a MSD dist. and 6AL box. 750 Holly on a RPM performer. Sounds about right to me. Oh and the NASCAR guys are running their SB's to 9000 but then they got more money than God.

[ January 27, 2003: Message edited by: Howard Jones ]

[ January 27, 2003: Message edited by: Howard Jones ]

Steve

Good point. BIG difference in rpm limit between old hydraulic cams/springs and

new tech roller cam/springs.

I had a 302 hydraulic years ago that failed

when I floated a valve due to weakened

valve springs. I was only turning 5500.

MikeD

Good point. BIG difference in rpm limit between old hydraulic cams/springs and

new tech roller cam/springs.

I had a 302 hydraulic years ago that failed

when I floated a valve due to weakened

valve springs. I was only turning 5500.

MikeD

Robert Logan

Defunct Manufactuer - Old RF Company

A little of course here but the story is true !!!

The maximum velocity of a piston is a staggering 22,000 feet / second. This is a number that has been calculated and proven by the F1 teams. The revs is therefore very important but also the stroke of the engine.

This is the major reason that why those beautiful F1 engines rev so HARD.

Best wishes,

Robert

The maximum velocity of a piston is a staggering 22,000 feet / second. This is a number that has been calculated and proven by the F1 teams. The revs is therefore very important but also the stroke of the engine.

This is the major reason that why those beautiful F1 engines rev so HARD.

Best wishes,

Robert

Ross Nicol

GT40s Supporter

Guys

Why do you think the v8 supercars in Australia and Nascars in the USA use 4 bolt main bearing caps and steel cranks? Because you can rev higher than a stock block and cast crank.The machine shop who built up my 2 bolt main HO motor described the webbing as very thin, and guess what? They do the machining for a lot of the v8 supercars which use R302 4 bolt blocks and they rev these babies to 7500 revs all day.My limit is 6500 because I don't want to have a bottom end failure. 2 bolt main blocks typically fail in the main bearing webbing area.

Regards Ross

Why do you think the v8 supercars in Australia and Nascars in the USA use 4 bolt main bearing caps and steel cranks? Because you can rev higher than a stock block and cast crank.The machine shop who built up my 2 bolt main HO motor described the webbing as very thin, and guess what? They do the machining for a lot of the v8 supercars which use R302 4 bolt blocks and they rev these babies to 7500 revs all day.My limit is 6500 because I don't want to have a bottom end failure. 2 bolt main blocks typically fail in the main bearing webbing area.

Regards Ross

Brett James-McCall

Moderator

Peeps, Edelbrock reckon 6500 for their RPM package. This is using TRW +30 pistons, the RPM heads, cam and manifold. However, Edelbrock have advised me that it is better to run one of their 600cfm Performer cabs rather than the 750cfm carb as staed on the website. For full details go to http://www.edelbrock.com/automotive/7121pp.html

<BLOCKQUOTE><font size="1" face="Verdana, Helvetica, sans-serif">quote:</font><HR>Originally posted by Ian K:

With a girdle, forged crank/rods, correct cam, and good valvetrain, a 302/306 can hit 8000 without much concern. The block is designed to do this.<HR></BLOCKQUOTE>

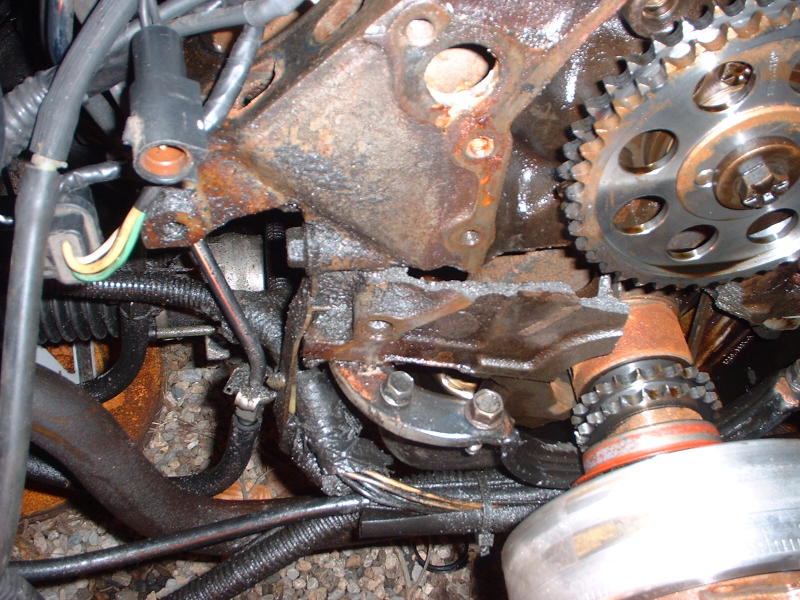

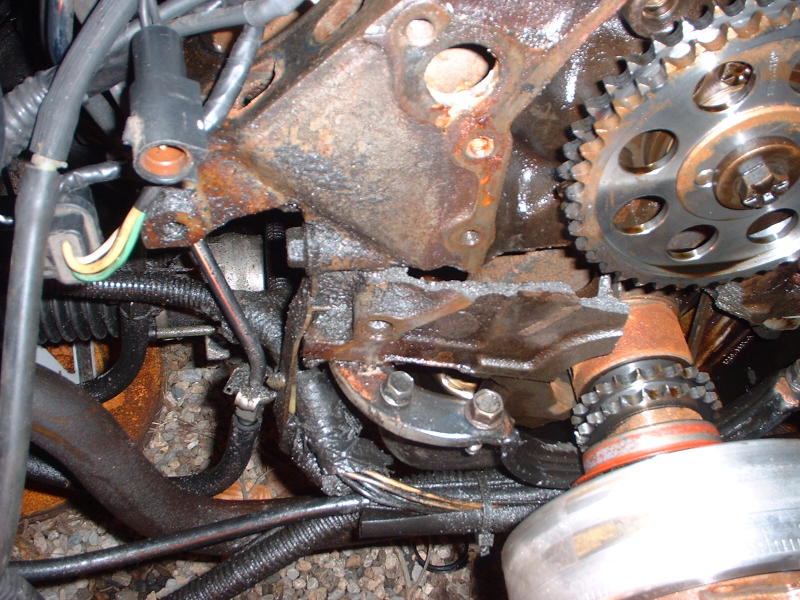

Sorry, Ian, but that's incorrect; the small-block Ford was not designed for high-rev operation. The stock 302 block uses two-bolt main bearing caps, and I can guarantee it will not live long at 8,000 rpm, even with a stud girdle and a built lower end. Here are some photos of a SBF block failure attributed to over-revving and a stock balancer:

[ January 28, 2003: Message edited by: Mark Worthington ]

With a girdle, forged crank/rods, correct cam, and good valvetrain, a 302/306 can hit 8000 without much concern. The block is designed to do this.<HR></BLOCKQUOTE>

Sorry, Ian, but that's incorrect; the small-block Ford was not designed for high-rev operation. The stock 302 block uses two-bolt main bearing caps, and I can guarantee it will not live long at 8,000 rpm, even with a stud girdle and a built lower end. Here are some photos of a SBF block failure attributed to over-revving and a stock balancer:

[ January 28, 2003: Message edited by: Mark Worthington ]

Mark

What do you feel is safe for my 427?

I've use 7000 for years without any problems.

Roller cams etc.

Best

What do you feel is safe for my 427?

I've use 7000 for years without any problems.

Roller cams etc.

Best

The 302 is an oversquare design, so should be good for high RPMs:

<BLOCKQUOTE><font size="1" face="Verdana, Helvetica, sans-serif">quote:</font><HR> Large bore, short stroke designs (oversquare) tend to be good breathers because larger intake and exhaust valves fit in the bore, and less valve area is shrouded by the cylinder walls. The short stroke supports higher rpm because the piston doesn’t have to travel as far per stroke, and longer connecting rods are easier to package into such an engine by the designer without having overall engine height grow clumsily high. Long rods slow piston acceleration at the top and bottom of each stroke, which allows higher rpm before critical stresses are reached. Thus, oversquare engines are associated with sporty, higher-revving applications. <HR></BLOCKQUOTE>

(http://www.roadandtrack.com/technical/articledisplay.asp?articleid=425)

That said, it's true that the entire engine has to be up to it. I've heard it's the stock rod bolts that are the main concern when trying to turn high RPMs. And since I've never tried to build one that'll rev that high, I'll let the experts speak from experience on what the real limits are...

<BLOCKQUOTE><font size="1" face="Verdana, Helvetica, sans-serif">quote:</font><HR> Large bore, short stroke designs (oversquare) tend to be good breathers because larger intake and exhaust valves fit in the bore, and less valve area is shrouded by the cylinder walls. The short stroke supports higher rpm because the piston doesn’t have to travel as far per stroke, and longer connecting rods are easier to package into such an engine by the designer without having overall engine height grow clumsily high. Long rods slow piston acceleration at the top and bottom of each stroke, which allows higher rpm before critical stresses are reached. Thus, oversquare engines are associated with sporty, higher-revving applications. <HR></BLOCKQUOTE>

(http://www.roadandtrack.com/technical/articledisplay.asp?articleid=425)

That said, it's true that the entire engine has to be up to it. I've heard it's the stock rod bolts that are the main concern when trying to turn high RPMs. And since I've never tried to build one that'll rev that high, I'll let the experts speak from experience on what the real limits are...

G

Guest

Guest

RPM is often limited by the strength of the return springs on the valves which is, in turn, limited by the type of lifters used. I have read one article where they claimed to get ~7K RPM with hyd. rollers. I am real curious what the real life limit you all have run into with hyd. lifters (flat or roller)?

<BLOCKQUOTE><font size="1" face="Verdana, Helvetica, sans-serif">quote:</font><HR>Originally posted by MK -IV J6:

Mark

What do you feel is safe for my 427?

I've use 7000 for years without any problems.

Roller cams etc.

Best<HR></BLOCKQUOTE>

Jim, I'm not as familiar with the 427 as I am with the small-block engines. Yours is a side-oiler, right? Screw-in core (freeze) plugs? Tunnel-port heads with the nearly circular intake ports? I would also guess that your engine uses the "LeMans" connecting rods that are also used in the 427 SOHC, notable in that they use cap screws (12-point head with undercut shank) instead of the bolts and nuts used on most production 427 FEs.

As you know, the self-imposed redline on the 427 at LeMans was something like 6,200 rpm. The 427 SOHC was good for up to 7,500 rpm, and it uses the same block (with cross-bolted mains) as the 427 FE. Therefore, I would think that short bursts up to 7,000 rpm are fine but I would keep sustained engine speeds at or below 6,000 rpm.

Lyn, I've never seen anyone rev a hydraulic cam much past 7,000 rpm.

Mark

What do you feel is safe for my 427?

I've use 7000 for years without any problems.

Roller cams etc.

Best<HR></BLOCKQUOTE>

Jim, I'm not as familiar with the 427 as I am with the small-block engines. Yours is a side-oiler, right? Screw-in core (freeze) plugs? Tunnel-port heads with the nearly circular intake ports? I would also guess that your engine uses the "LeMans" connecting rods that are also used in the 427 SOHC, notable in that they use cap screws (12-point head with undercut shank) instead of the bolts and nuts used on most production 427 FEs.

As you know, the self-imposed redline on the 427 at LeMans was something like 6,200 rpm. The 427 SOHC was good for up to 7,500 rpm, and it uses the same block (with cross-bolted mains) as the 427 FE. Therefore, I would think that short bursts up to 7,000 rpm are fine but I would keep sustained engine speeds at or below 6,000 rpm.

Lyn, I've never seen anyone rev a hydraulic cam much past 7,000 rpm.

Mark

That's what I figured as well. When I say up to 7000 I mean for a very short time.

You have my engine right, Heads are iron TP.

I have a set of SK alum TP heads but I don't think they were ever used and I believe my car was raced with the heads on it now.

Best

Jim

That's what I figured as well. When I say up to 7000 I mean for a very short time.

You have my engine right, Heads are iron TP.

I have a set of SK alum TP heads but I don't think they were ever used and I believe my car was raced with the heads on it now.

Best

Jim

Ross Nicol

GT40s Supporter

Mark

Seems like you and I are the only ones on this forum that know the bottom end strength on these blocks is what sets the rev limitation.And by the way where do I buy those rods with the aerodynamic kink in them.I reckon they will reduce windage too.

Regards Ross

Seems like you and I are the only ones on this forum that know the bottom end strength on these blocks is what sets the rev limitation.And by the way where do I buy those rods with the aerodynamic kink in them.I reckon they will reduce windage too.

Regards Ross

G

Guest

Guest

Ross, there is no doubt that the strength of the bottom end and its ability to withstand the forces created by the rotating mass is what sets the ultimate capacity of a particular engine to develop RPM without breaking. However, even if you were to make the rotating mass out of a material that would make a given block capable of handling 15K RPM, if the valves started floating at 8K, it would never get there. Bottom line, while I don't disagree with you, it is just not that simple when you are talking about what RPM and engine "would" develop versus what it "could" develop if ......

Similar threads

- Replies

- 13

- Views

- 1K

- Replies

- 61

- Views

- 4K