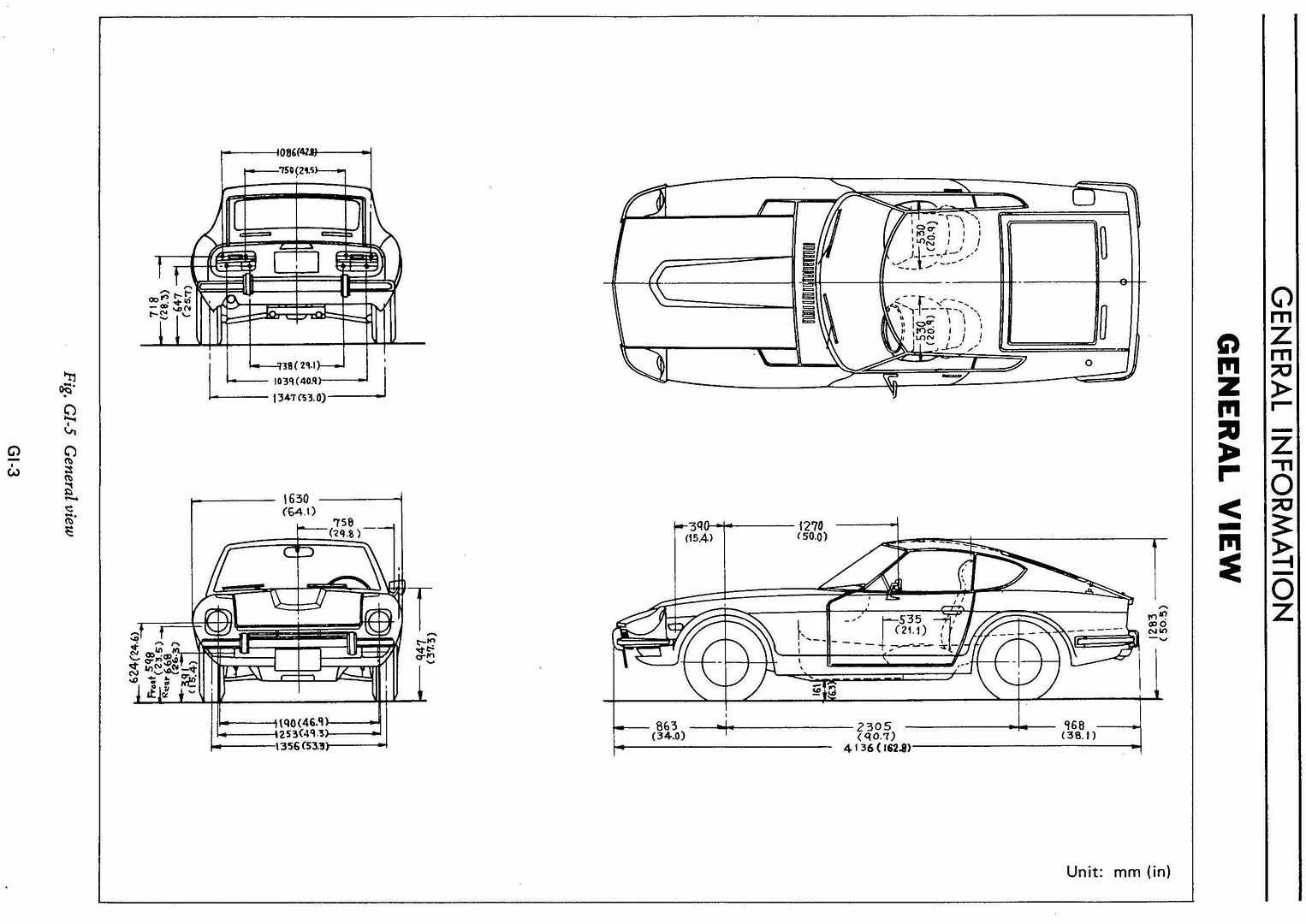

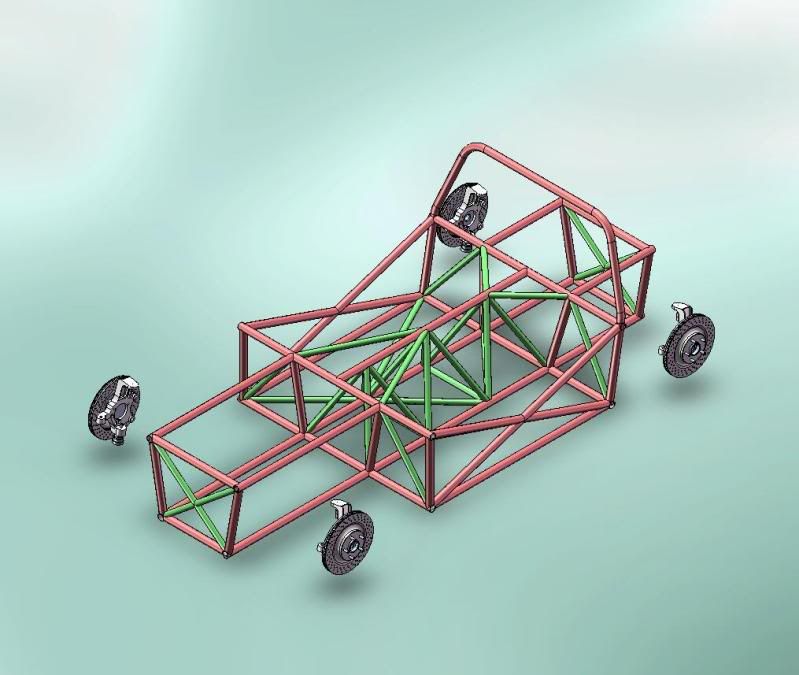

I'm new here. I've just made the jump to doing a full tube frame Datsun 280z. The car will be powered by a Toyota 2JZ turbocharged engine. It will be backed by a Jerico or Super T10 transmission. Not sure just yet on that portion of things. The engine will be a structural member of the front suspension. I will be using C5 front uprights. I will be doing custom steel rear uprights with 300zxtt differential, axles, and hubs. I will have fairly long 4130 SLA suspension. The engine will be completely behind the front wheel centerline.

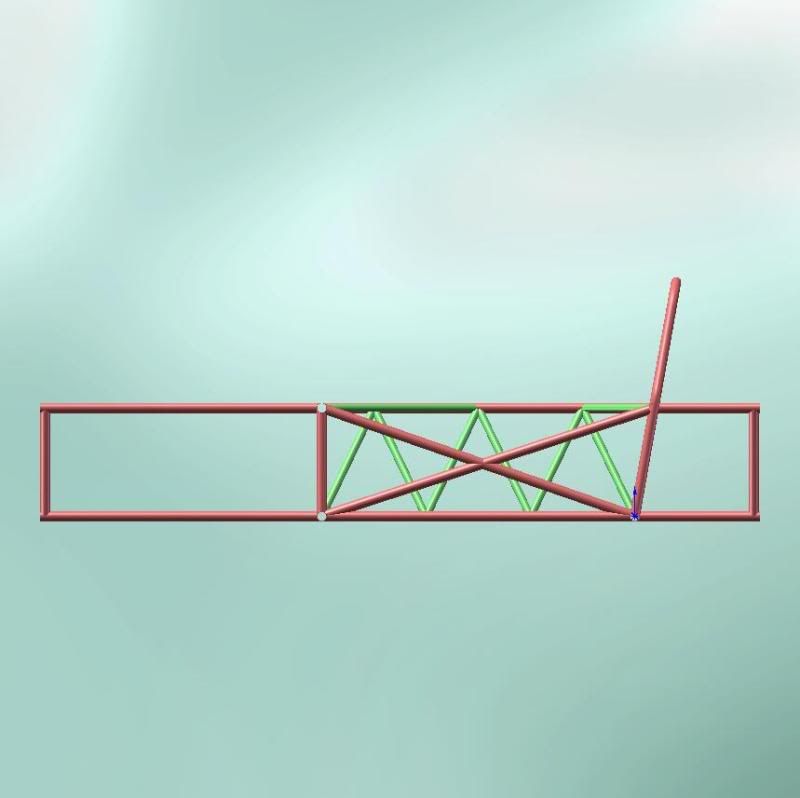

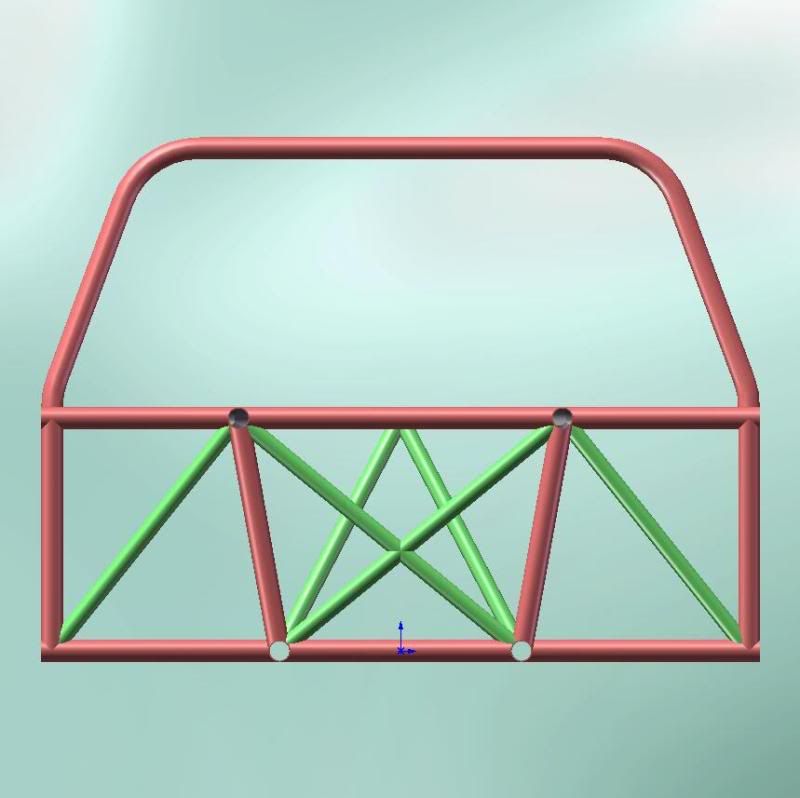

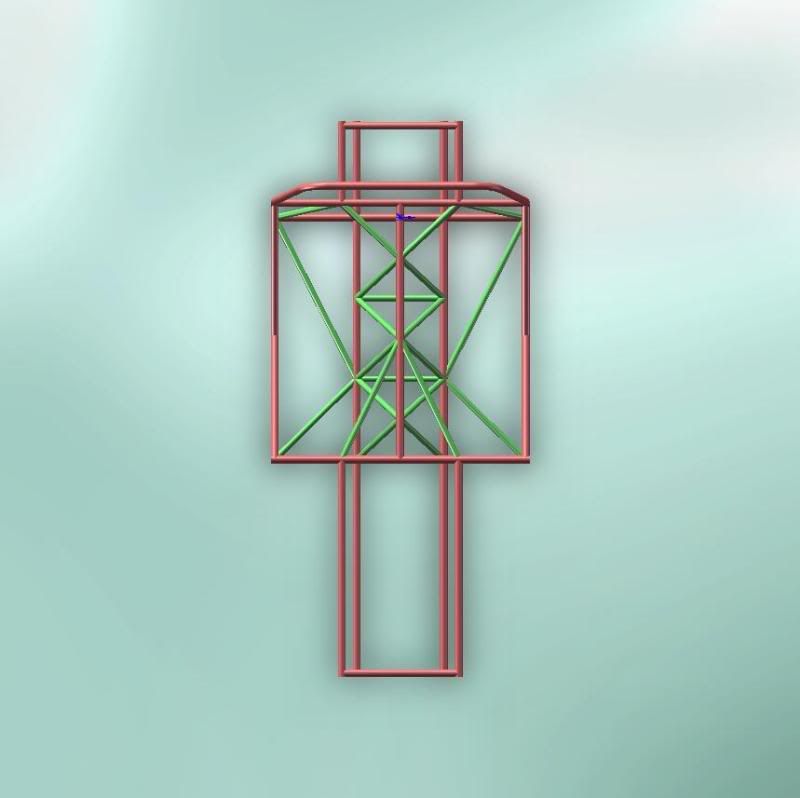

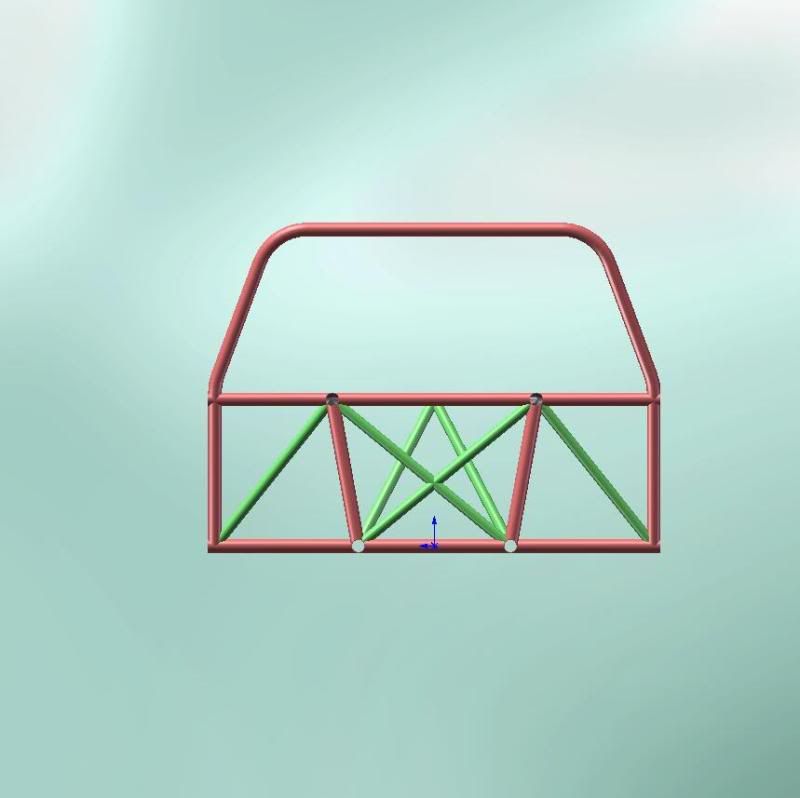

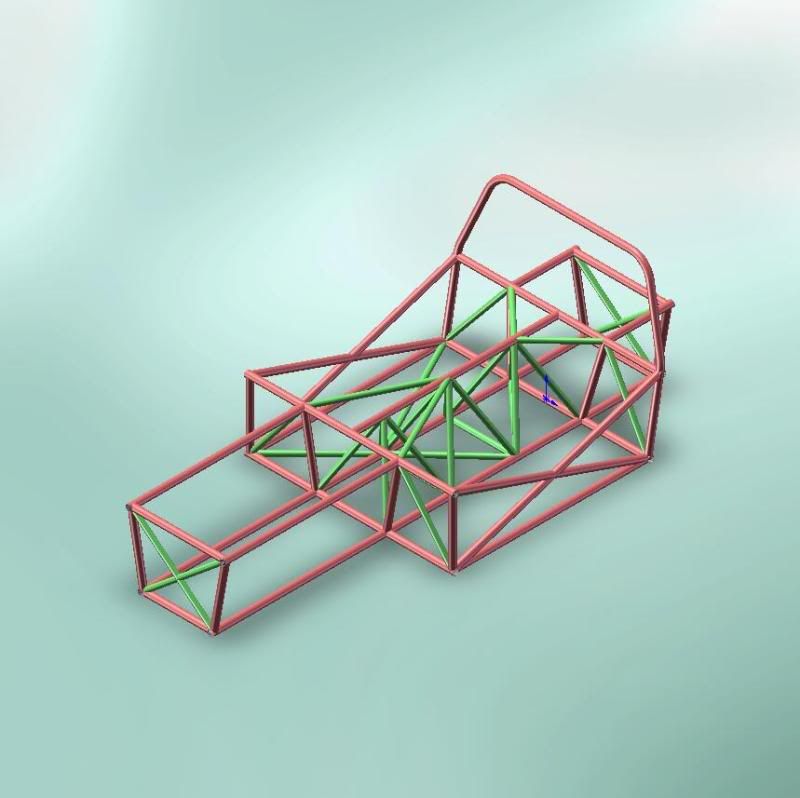

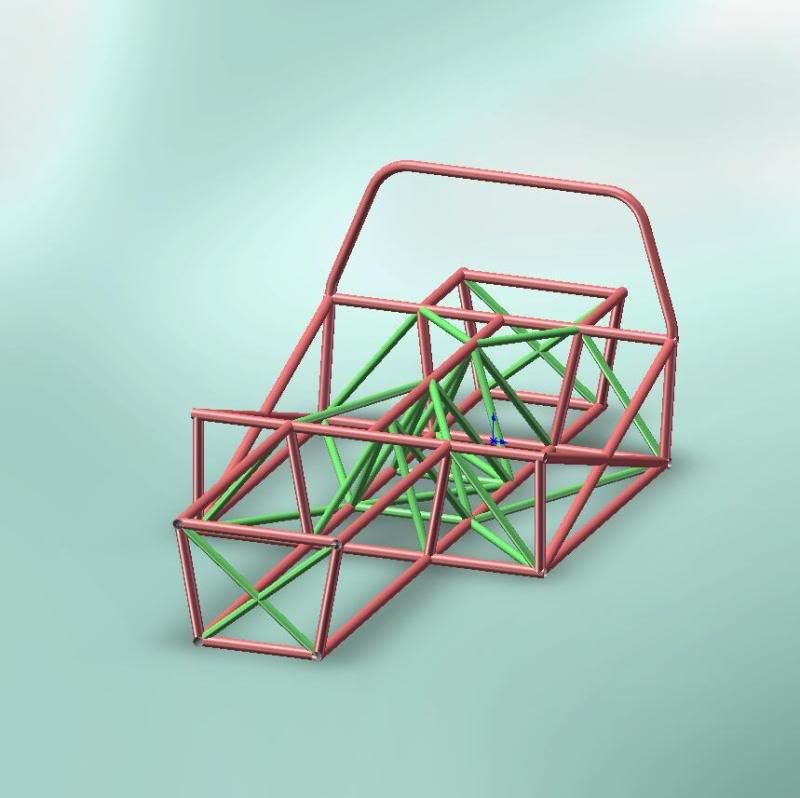

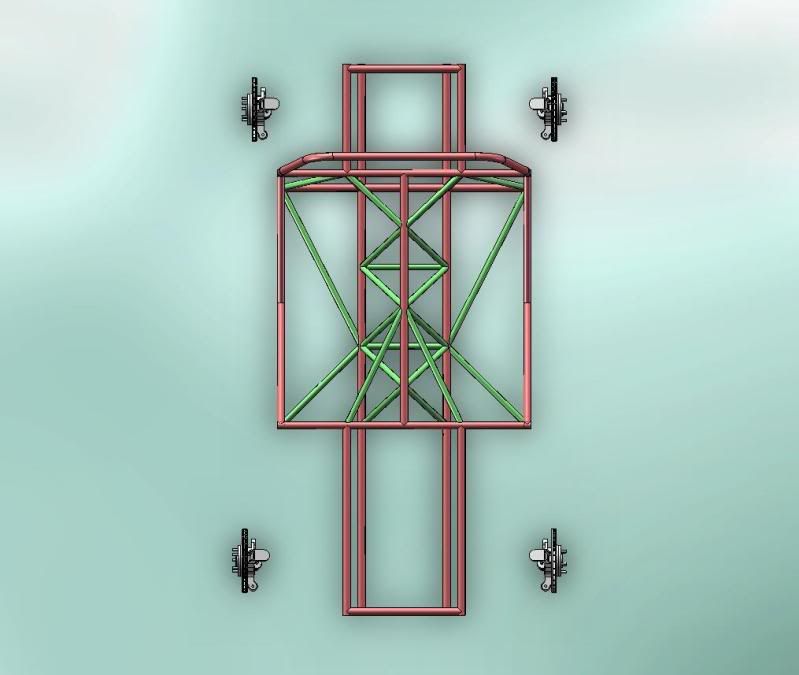

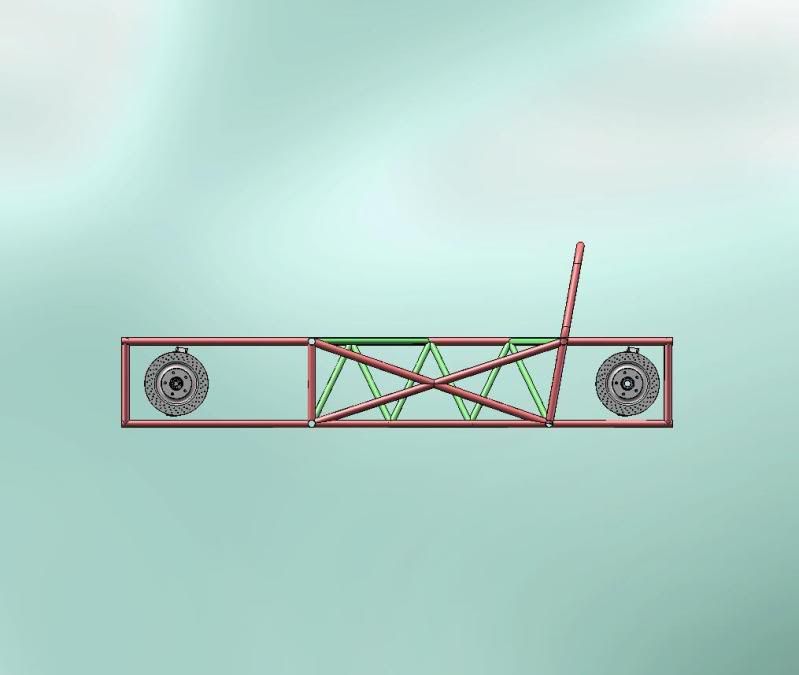

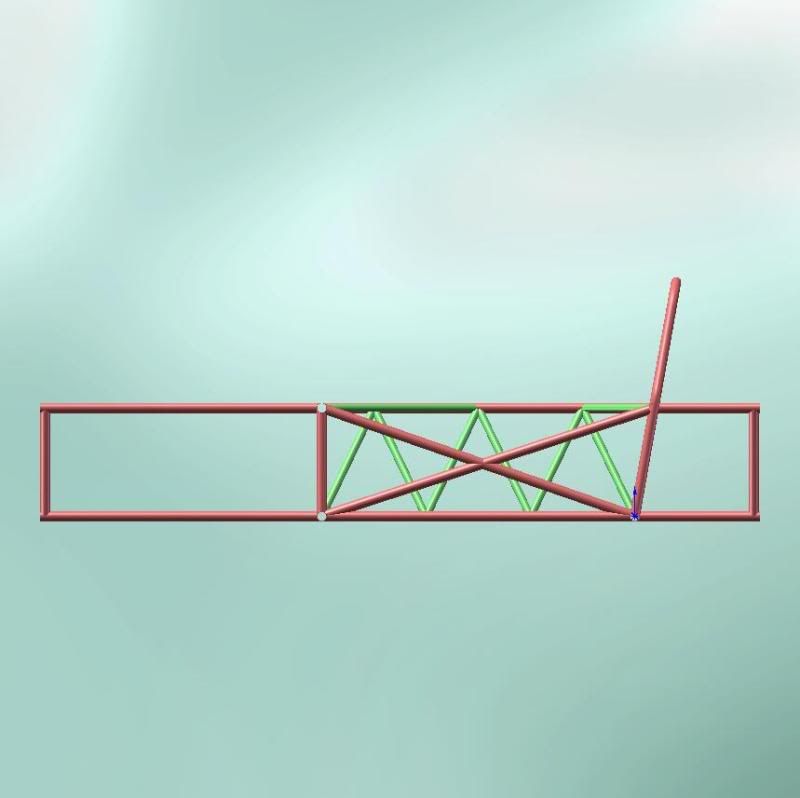

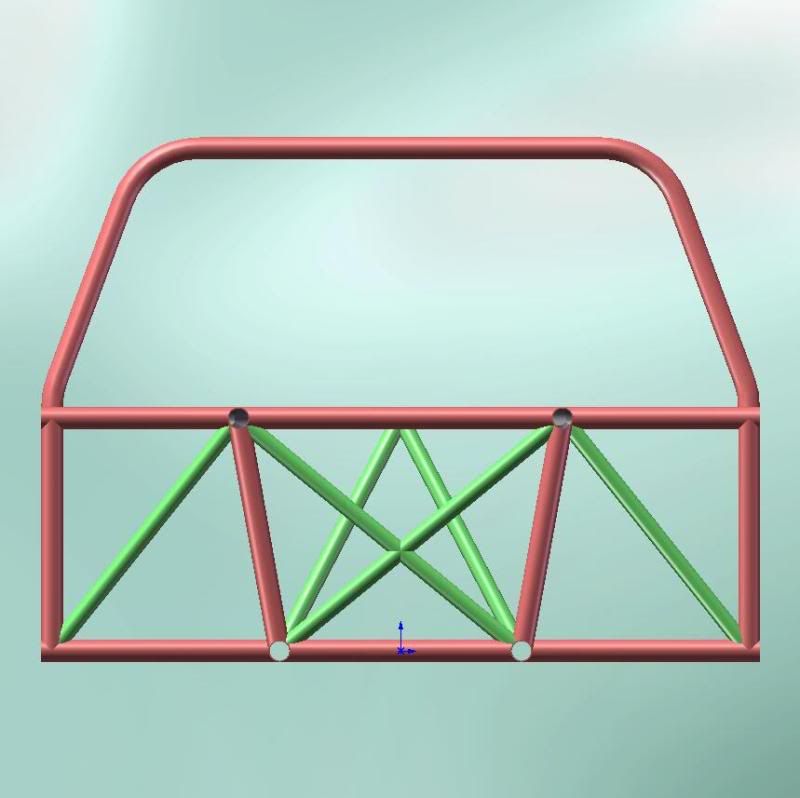

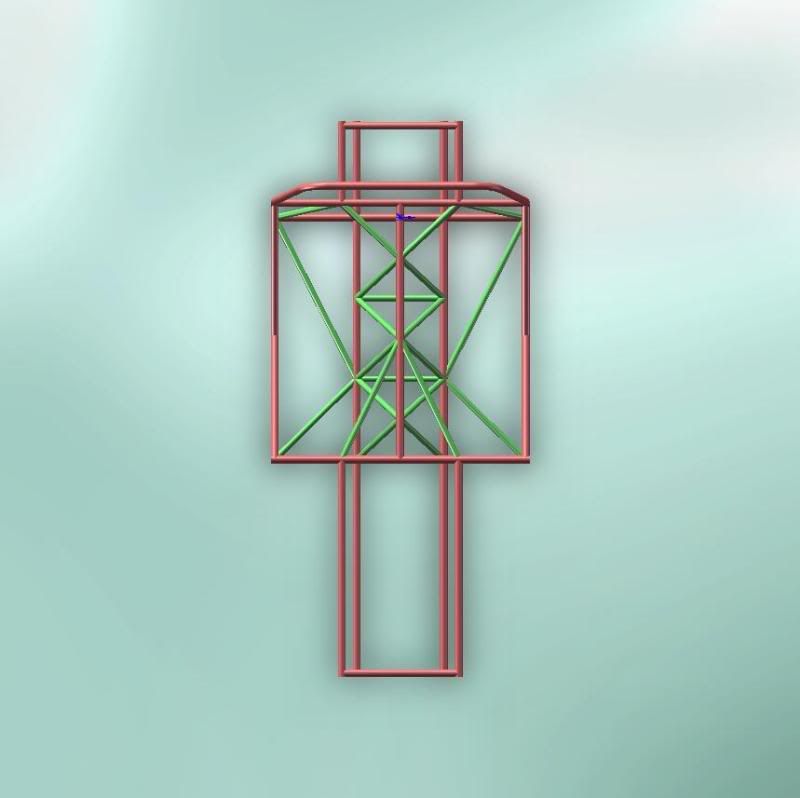

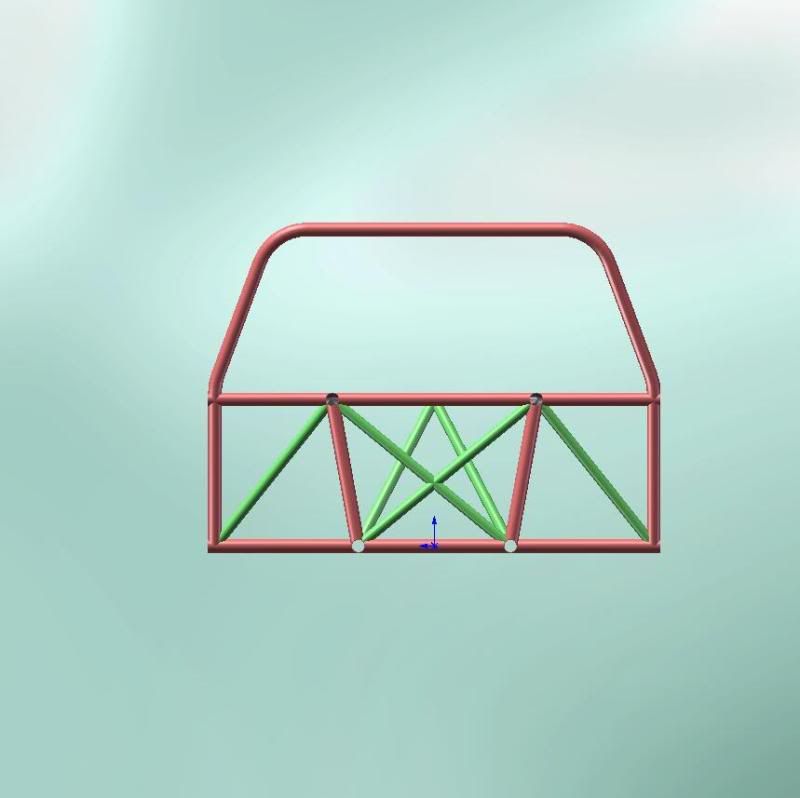

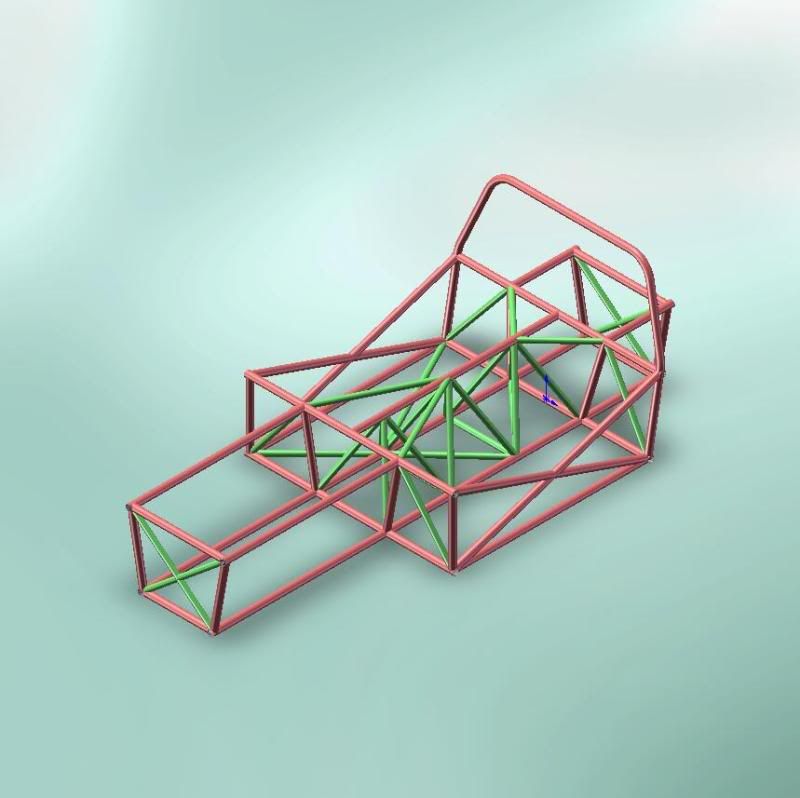

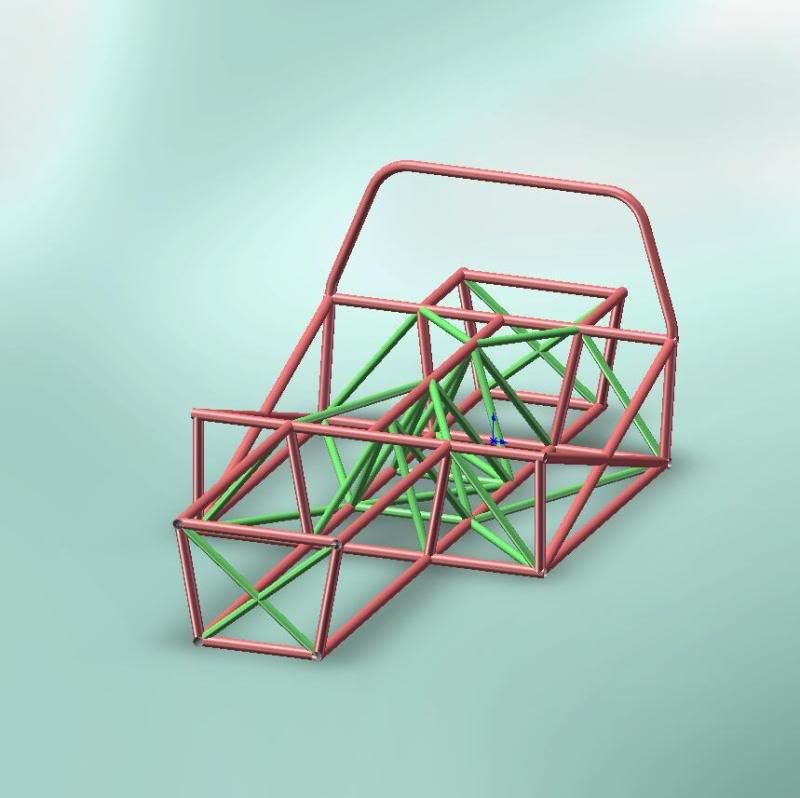

This is my first stab at designing a tortionally rigid tube frame. It currently weighs 185 lbs for the frame. The red bars are 1.625 X 0.083 4130 tubing and the green bars are 1.25 X 0.065 4130 tubing. I need to add more triangulation up front and at the rear. My next step will be taking more exact measurements of the drivetrain to place in cad.

The final 2 pictures show the wide fender kit that I've purchased for for the buildup. There won't be much datsun left in this project. I just want to have enough of it so I can register it, insure it and drive it on the street on that occasional nice summer day.

My overall goals for this project are sub 2000lbs and 600 hp.

Regards,

Justin

This is my first stab at designing a tortionally rigid tube frame. It currently weighs 185 lbs for the frame. The red bars are 1.625 X 0.083 4130 tubing and the green bars are 1.25 X 0.065 4130 tubing. I need to add more triangulation up front and at the rear. My next step will be taking more exact measurements of the drivetrain to place in cad.

The final 2 pictures show the wide fender kit that I've purchased for for the buildup. There won't be much datsun left in this project. I just want to have enough of it so I can register it, insure it and drive it on the street on that occasional nice summer day.

My overall goals for this project are sub 2000lbs and 600 hp.

Regards,

Justin