You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel return port in gas tank lower than maximum fill level?

- Thread starter EFNFAST

- Start date

The higher the better Alex, I cant remember which system your fitting this week , if its the return from the pressure regulator for the carb or heaven forbid an EFI setup it should ideally be as high as possible & directed into the main fuel tank. There would be times with a full tank that the level would cover the return anyway regardless of where its situated. Wont matter much on an EFI setup, but with a carb setup, discharging the the excess from a regulator against a 'head' of fuel could alter the pressure slightly.

, if its the return from the pressure regulator for the carb or heaven forbid an EFI setup it should ideally be as high as possible & directed into the main fuel tank. There would be times with a full tank that the level would cover the return anyway regardless of where its situated. Wont matter much on an EFI setup, but with a carb setup, discharging the the excess from a regulator against a 'head' of fuel could alter the pressure slightly.

Fran is test fitting a carb for me, so I'm hoping its for carb

But let me word my question better.

Here's my gas tank. I'm talking about the return line from the regulator to the gas tank.

I drew 2 rough lines. The bottom red line is the bottom of the return line. The top red line is the max fill line (any higher than this and it comes pouring out my vent line).

As you can see, if I fill the tank to the absolute max it can take, the return line will be well covered by the fuel (although not for long, lol)

Is this okay, or should the return line ALWAYS be above the fuel line? The reason I ask is because the A1000 needs the return line to keep itself cool - so if the tank is filled to max and the return line is a bit below the max mark, will the fuel still cycle back in and kepe the a1000 cool, or will bad things happen?

But let me word my question better.

Here's my gas tank. I'm talking about the return line from the regulator to the gas tank.

I drew 2 rough lines. The bottom red line is the bottom of the return line. The top red line is the max fill line (any higher than this and it comes pouring out my vent line).

As you can see, if I fill the tank to the absolute max it can take, the return line will be well covered by the fuel (although not for long, lol)

Is this okay, or should the return line ALWAYS be above the fuel line? The reason I ask is because the A1000 needs the return line to keep itself cool - so if the tank is filled to max and the return line is a bit below the max mark, will the fuel still cycle back in and kepe the a1000 cool, or will bad things happen?

Cannot 'see' any problems with that setup Alex, but wont your 'vent' line run to a higher point in the car to prevent any loss of fuel overboard? Even if your tank is filled to the very top by the -8 # you have drawn on it its only a few inches above, but if in doubt you could try either of these ideas, having a couple of extra fittings in a tank can come in handy especially with EFI.

Last edited:

The vent is a slight concern, but that's the highest point I can stick the vent fitting at - any higher and you run into the rear crossbeam

I don't have any pictures of it, but I have the vent hose running upwards for a little bit, then downwards (no u-trap anywhere) so if fuel does get into it it should slosh back into the tank, or if it's an extreme slosh, slosh out onto the ground, but not get trapped anywhere

I don't have any pictures of it, but I have the vent hose running upwards for a little bit, then downwards (no u-trap anywhere) so if fuel does get into it it should slosh back into the tank, or if it's an extreme slosh, slosh out onto the ground, but not get trapped anywhere

Wouldn't that be a bad idea? - you'd have to basically form a U and go underneath the rear crossbeam. If any fuel sloshes into the 'U' it isn't going to come back out unless you have a really hard slosh.

I could put the vent fitting there and run it upwards and back, buuuuuut then I'd have to chop into the rear aluminum bulkhead panel, and I don't really feel like doing that because I'd rather not have a hose sticking in the interior that you can see.

More thought, always more thought, heh.

Btw, in terms of positioning the return bung in a fuel tank, how low below the top of the fill line would you be comfortable placing it in a small fuel tank (8gal) before you'd be worried about it causing any type of pressure issues or backflow issues?

The reason I ask is because I've been researching the issue and it seems that a lot of people will run their return line to their sump (yikes, that's low!). Some have problems with it, some (those with smaller cells like 5gal) don't seem to have problems. Obviously the ideal is dumping it back at the top, but if that isn't an option how low is too low?

I could put the vent fitting there and run it upwards and back, buuuuuut then I'd have to chop into the rear aluminum bulkhead panel, and I don't really feel like doing that because I'd rather not have a hose sticking in the interior that you can see.

More thought, always more thought, heh.

Btw, in terms of positioning the return bung in a fuel tank, how low below the top of the fill line would you be comfortable placing it in a small fuel tank (8gal) before you'd be worried about it causing any type of pressure issues or backflow issues?

The reason I ask is because I've been researching the issue and it seems that a lot of people will run their return line to their sump (yikes, that's low!). Some have problems with it, some (those with smaller cells like 5gal) don't seem to have problems. Obviously the ideal is dumping it back at the top, but if that isn't an option how low is too low?

Your Sump if gravity fed from the tank will have a greater head of fuel above it, the guys with smaller tanks have a lesser amount of 'head' or fuel therefore a smaller problem , I really dont think you will have any issues with your current setup & dont think the small 'U' would cause an issue in that additional vent if you decide to fit it since the amount of fuel head above it is minimal even with tank topped off. The higher the better, that about sum's it up.

, I really dont think you will have any issues with your current setup & dont think the small 'U' would cause an issue in that additional vent if you decide to fit it since the amount of fuel head above it is minimal even with tank topped off. The higher the better, that about sum's it up.

Afterthoughty... If that large fitting with blue tape is your filler, you will need a vent from highest point to the filler tube in order to properly fill the tank, otherwise its going to trap air in that upper portion above the vent fitting every time you fill it, & burp & phart fuel all over EFN in the process, dont want you to turn yourself into a Roman Candle just yet

Afterthoughty... If that large fitting with blue tape is your filler, you will need a vent from highest point to the filler tube in order to properly fill the tank, otherwise its going to trap air in that upper portion above the vent fitting every time you fill it, & burp & phart fuel all over EFN in the process, dont want you to turn yourself into a Roman Candle just yet

Last edited:

Yea, that sums up my thoughts as well (higher the better) - unfortunately silly triangle shaped objects make this a problem over square shaped objects, lol!

I just like to think all this through now because it's a heck of a lot easier to change a fuel setup now than when there's fuel in it!

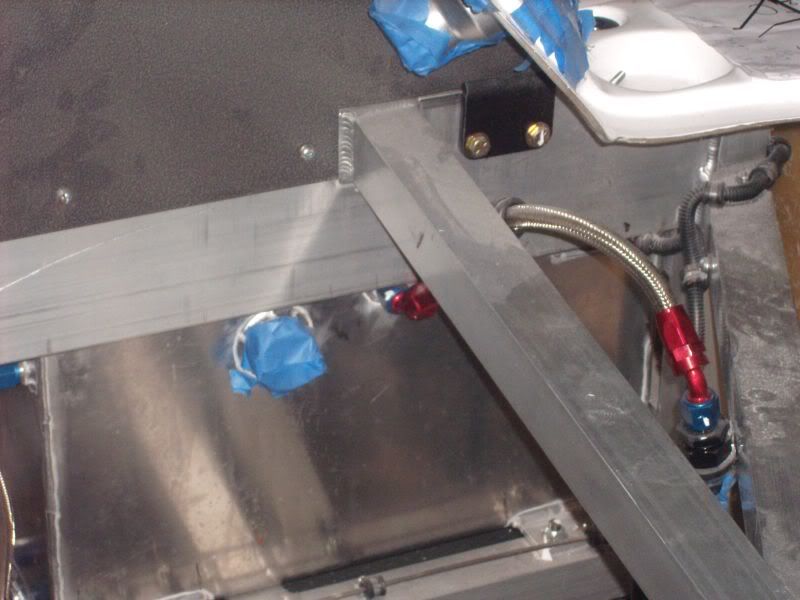

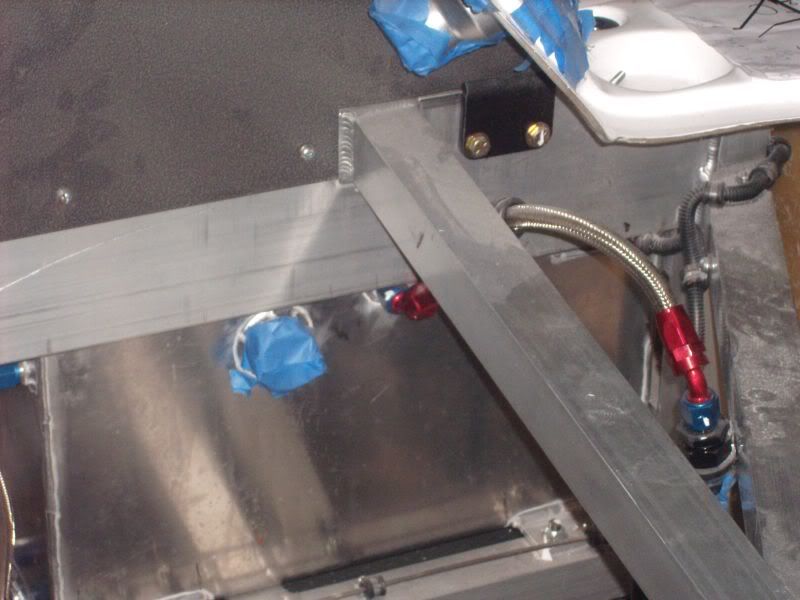

Btw, here's 2 pictures with the tank mounted and vent in place.

If I fill the tank up to the bottom of the vent, I can get 29 1/2L in. So if I leave a few litres out, say only filling 25L, then I think even though it isn't ideal, I should be okay-ish .... it would take a violent slosh to get fuel into the vent line, but then it would drain back down into the tank immediately (unless it was a huge surge, in which case it would puke it out)

Also, if you see the return line in the first picture (far left side of the tank), filling to 25L would have the return above the max fill line. Filling to 29L (max) would have it ~ 1/4'' below the max fill line, so I guess that isn't too too horrible.

It may be kind of hard to tell from the last picture, but by placing a vent fitting where you suggested and coming under the crossbeam, I don't think would help that much - it'd only be ~ 1/4'' higher than the current fitting, not to mention the potential u-trap.

The one thought I did have though is what happens if I added another vent line into the fill neck, and t'd that line into this vent line? Good idea, or potentially bad idea?

I just like to think all this through now because it's a heck of a lot easier to change a fuel setup now than when there's fuel in it!

Btw, here's 2 pictures with the tank mounted and vent in place.

If I fill the tank up to the bottom of the vent, I can get 29 1/2L in. So if I leave a few litres out, say only filling 25L, then I think even though it isn't ideal, I should be okay-ish .... it would take a violent slosh to get fuel into the vent line, but then it would drain back down into the tank immediately (unless it was a huge surge, in which case it would puke it out)

Also, if you see the return line in the first picture (far left side of the tank), filling to 25L would have the return above the max fill line. Filling to 29L (max) would have it ~ 1/4'' below the max fill line, so I guess that isn't too too horrible.

It may be kind of hard to tell from the last picture, but by placing a vent fitting where you suggested and coming under the crossbeam, I don't think would help that much - it'd only be ~ 1/4'' higher than the current fitting, not to mention the potential u-trap.

The one thought I did have though is what happens if I added another vent line into the fill neck, and t'd that line into this vent line? Good idea, or potentially bad idea?

In that picture, the top of the filler neck is roughly even with the bottom of the vent tube (~29 1/2 L).

So my plan would be to atmost fill it with 27-28L since that brings it to the bottom of the filler neck.

I'm not so much concerned about my limited fuel capacity as i am doing this safely (i.e., not a rolling fire trap, heh)

So my plan would be to atmost fill it with 27-28L since that brings it to the bottom of the filler neck.

I'm not so much concerned about my limited fuel capacity as i am doing this safely (i.e., not a rolling fire trap, heh)

Hi Alex,

Thread high jack coming....

Are you running a check valve on the return line? I've seen an arguement that running the return (assuming EFI) to the bottom of the tank is safer as in roll over fuel cant get out from it, but roll over check valves look like the safest option I think?

I'm planning to use roll over check valves for both the vent and EFI return and I'm going to use a filler plate with a flappy valve in it so in the event of the filler neck being ripped off there isn't a 2" hole for the fuel to escape from (all from Fuel Safe).

I also thought the fuel return just emptying into the top of the tank would make an annoying noise (like a drunk guy peeing non-stop), being so close to the passenger compartment.

Thoughts?

Thread high jack coming....

Are you running a check valve on the return line? I've seen an arguement that running the return (assuming EFI) to the bottom of the tank is safer as in roll over fuel cant get out from it, but roll over check valves look like the safest option I think?

I'm planning to use roll over check valves for both the vent and EFI return and I'm going to use a filler plate with a flappy valve in it so in the event of the filler neck being ripped off there isn't a 2" hole for the fuel to escape from (all from Fuel Safe).

I also thought the fuel return just emptying into the top of the tank would make an annoying noise (like a drunk guy peeing non-stop), being so close to the passenger compartment.

Thoughts?

Julian

Lifetime Supporter

Also discharging below the fuel level witha downcomer avoids the possibility of static discharge. Virtually all industrial flammables tanks are designed with returns or fuel inlets below the liquid level.

In a longitudinal tank like the GT40 the fuel liquid head is not going to be very much to overcome.

In a longitudinal tank like the GT40 the fuel liquid head is not going to be very much to overcome.

Thoughts?

Yea - I hate you guys for making me re-think everything again and again, lol!:laugh:

I keeed, I keeed, I <3 all of you :heart:

Not going to use a check valve because it's just one more thing that can fail (And be a real PITTA to figure out). No roll-over valve in my vent line either. I thought this issue in graet depth when I vented it, and decided against it - if I were going to use a valve it would be a discriminator valve (lets air out, keeps fuel in) BUT when talking to Fuel Safe and others they recommended against it just because the valves can fail and then trap air as well ... not good!

I figure the chance of roll-over is minimal, so I'm not too worried.

Some people say running the return to the bottom (sump) is a good idea, some say it's a horrible idea. Honestly, after several hours reading and googlling I have NO idea what is proper anymore and what will/won't cause pressure issues. I'm just so confused

Also discharging below the fuel level witha downcomer avoids the possibility of static discharge. Virtually all industrial flammables tanks are designed with returns or fuel inlets below the liquid level.

In a longitudinal tank like the GT40 the fuel liquid head is not going to be very much to overcome.

*sigh* Alex hates fire hazards a lot.

I hadn't thought about static discharge with fuel continually pouring into the tank. Is this a serious risk to consider? Most fuel setups I'm familiar with just have a -6/8/10 bung at the top (or near the top) and fuel dumps into it.....

Dont see how your going to have a static discharge problem if you have braided fuel lines & the discharge is the fuel return ( braided ) & already connected to your alloy tank, its more likely to happen when you pull up to the gas station & touch the fuel pump nozzle to the nice alloy fuel tank connected to that alloy frame with lots of electrons buzzing around it................

Learn & Practice the M.I.S.S & K.I.S.S principle..

Learn & Practice the M.I.S.S & K.I.S.S principle..

Howard Jones

Supporter

This is how I did mine. I see no reason to extend the tank above the fill port. I needed a flat surface to mount all the stuff on including the level sender and vent and return port, and I wanted to pump from a sump at the center of the tank. Also everything can be removed from the tank for maintenance.

I also filled mine and found it will hold 14 gals as you see it.

I also filled mine and found it will hold 14 gals as you see it.

Attachments

Howard, do you have any pics of your sump? As you can see from mine, my sump is at the side of the tank - not my favorite location, but it was designed well enough that fuel starvation shouldn't be an issue unless I'm running reallly low and pull a very hard turn.

I can't figure out how you'd sump it at the back and have access to it, because the sump would sit below the rear crossbeam blocking access to it?

I can't figure out how you'd sump it at the back and have access to it, because the sump would sit below the rear crossbeam blocking access to it?

Similar threads

- Replies

- 15

- Views

- 2K

- Replies

- 98

- Views

- 16K