I'm trying to keep my fuel setup compact.

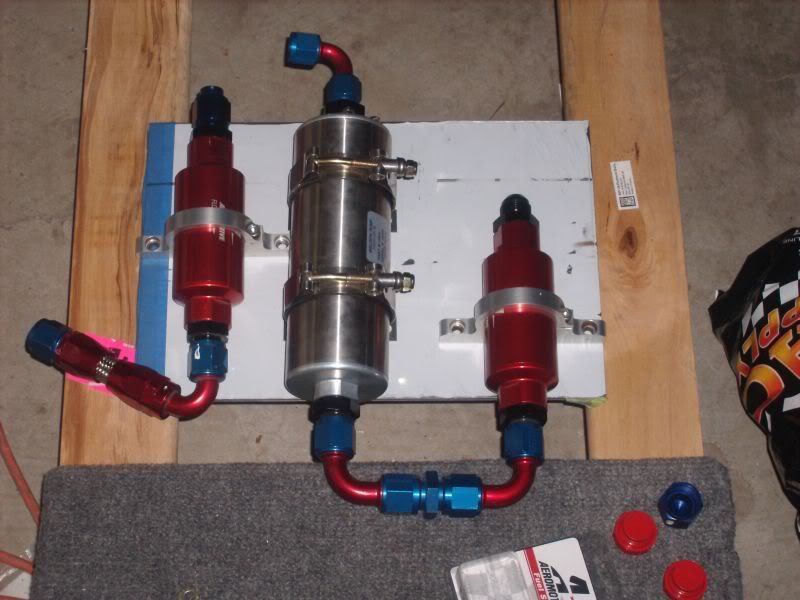

What I've got is basically this:

Note my awesome Weldon Racing pump - continual duty, no fuel controller needed, and flows up to 1600hp, muahahaha.

What I'm wondering is if you look at the bottom you have a 90* female/female on the filter and pump joined by a union. I will also be making the same connection at the top (female/female 90* with a union joining pump and post-pump filter).

I'm wondering if this is okay - will vibration cause these connections to loosen? I'd rather not use hose ends here because I'd have to signifigantly increase the size of the bracket. Here I can keep everything tight and compact.

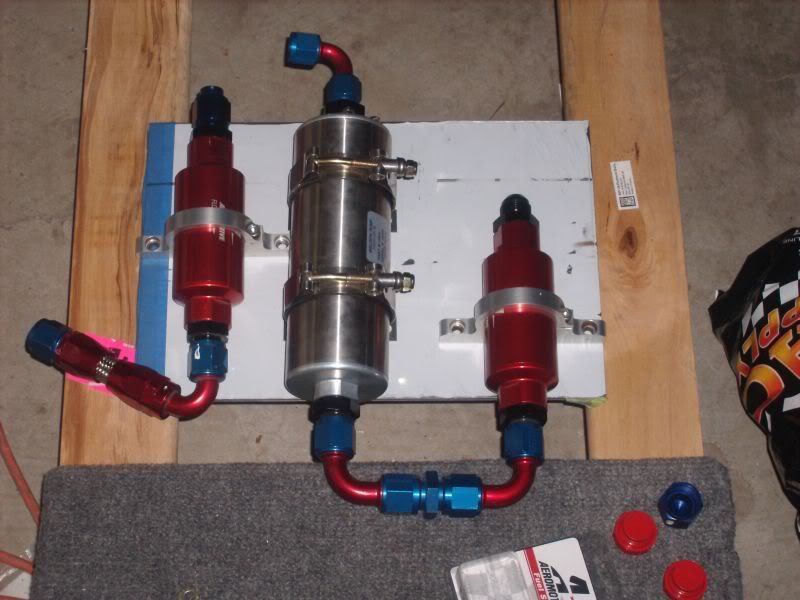

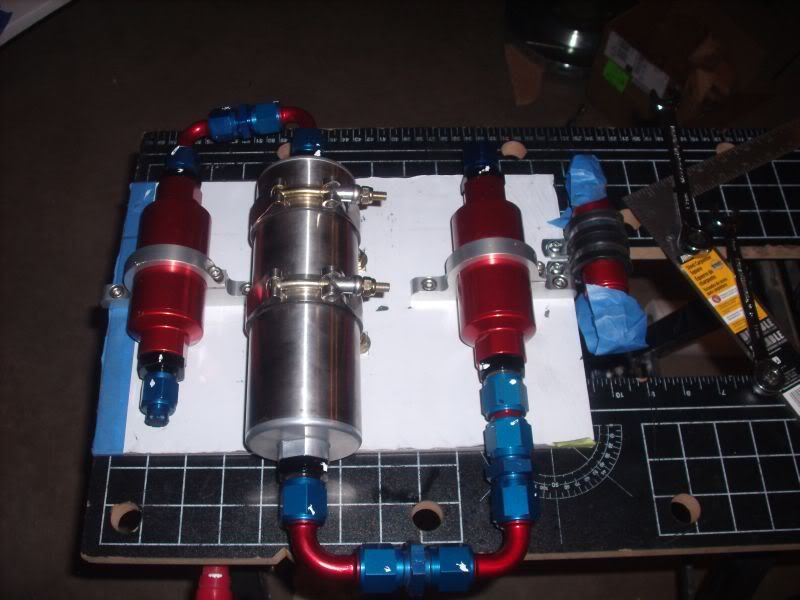

What I've got is basically this:

Note my awesome Weldon Racing pump - continual duty, no fuel controller needed, and flows up to 1600hp, muahahaha.

What I'm wondering is if you look at the bottom you have a 90* female/female on the filter and pump joined by a union. I will also be making the same connection at the top (female/female 90* with a union joining pump and post-pump filter).

I'm wondering if this is okay - will vibration cause these connections to loosen? I'd rather not use hose ends here because I'd have to signifigantly increase the size of the bracket. Here I can keep everything tight and compact.

.jpg&maxx=300&maxy=0)