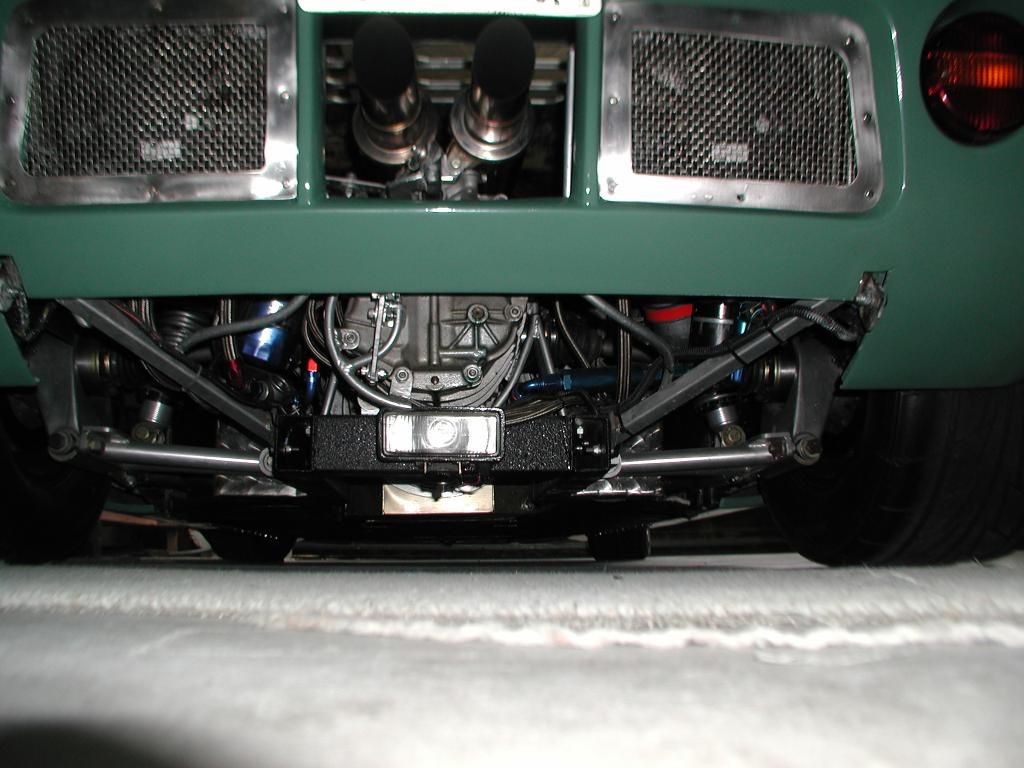

Info first. My engine setup is a 351W with a 930(inverted). I have a DRB. DRBs have a subframe members to support the engine and trans. So lets look at several issues you are facing. First let me say that my 930 sits on the frame.

The frame measures level on its feet, even with a 4" ground clearance in front and a 5" in the rear. I have a Kevko oil pan that is partitioned with trap valves to keep the oil around the pickup. It sits about an 1/8" lower than the frame and the level gauge on the valve covers measures dead level.

The pic is shot at an angle, so it looks like more. I also have a solid mount engine. The issue you have is that the deck height of the 351 is higher than the old 302. What ever pan you run, that is the best you will get. Not sure how the rear frame work looks on your car. What I can say is that if you have a true frame member at the rear anything similar to what my DRB is, you have an option, if your engine points down in the front. First, clamp a 2x4 to the bottom of you frame under the engine oil pan. Place the engine trans axle bolted together in the bay and let the engine sit on the 2x4. Measure the distance that separates the engine from the mount. That is where you want to build your mounts for the engine. With the trans sitting on the frame measure the valve cover to see if it is level. If it is then build your trans mount to the frame and bolt everything down. If it isn't raise the engine till it is. Measure the distance your engine is above the first measurement(engine to mount). If that measurement is greater than your frame you are out of luck, because your trans mount will be lower than all of your car.

If it is less than half, you can cut the frame in a saddle arrangement(U) for the trans to sit in.Weld in some steel to close up the face of the saddle. Your mounts will have to be solid back there as it will reinforce the frame. My suggestion is that it be a plate style mount to any bolts you can line up. If you can't then brace it to the side of the frame and add vertical pieces to the front and back of the cross member like an I beam arrangement to reinforce it at the saddle. I am not an engineer, so lets hear some thoughts on this.

If after all of this, the trumpets still hit the glass, then you will have to mill the top of the manifold the required distance for clearance,,,,,, or you can run it without a rear window ala Robert.

If this is clear as mud PM me and I can send you some drawings that might clear it up. My information is based on what one member did to the rear frame member of his DRB when he added a 5.4 to his build. Don't remember the trans he selected. As a last thought, if you wind up with a little nose down, you will have to run vents from the back of the intake to the front to eliminate steam pockets. That procedure is covered well elsewhere.

Bill