It's all about the use.

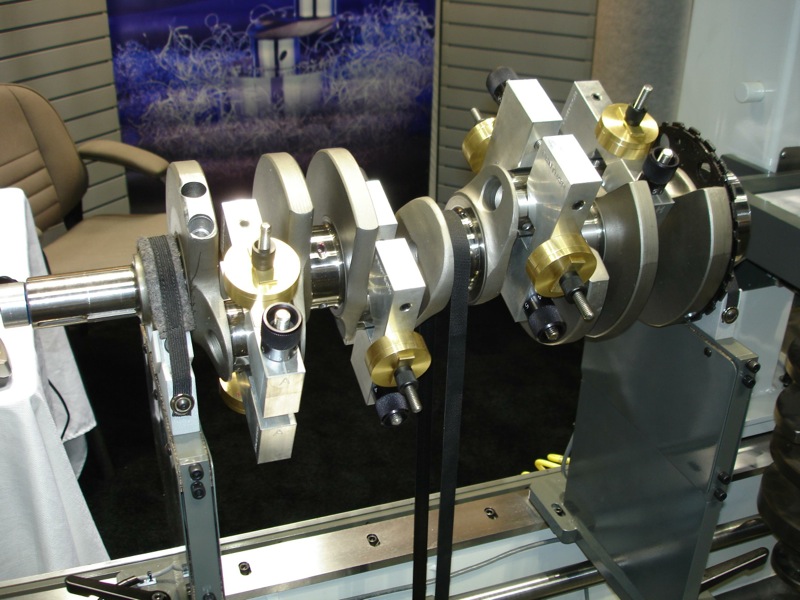

If you intend to take it to the track, even a few times a year then the engine rotating assembly needs to be balanced as an assembly by a qualified machine shop. Engines that are production built (ALL crate engines) are not balanced. They are part-specific weight selected. That means all the pistons, pins, rods, are selected individually in a range of weight groups, the crank machined to given tolerance, and then assembled. Tolerance stacking can then take the rotating assembly far out of the range of what would be considered a machine shop custom balanced engine. A qualified machine shop should be able to hold a less than 2 gram out of balance fairly easily with less than 1 gram as a target for the whole assembly. This would include your choice of the flywheel, clutch pressure plate, damper, and belt pulley.

Street rods, streetcars, or whatever you want to call them will never see engine revs remain above 3500-4000 RPMs for 30 mins at a time making 50 -100% of its potential HP. This is what happens on track if you are trying to maintain a quick pace. A street engine will spend the majority of its life at idle or at cruise speeds. They also will spend nearly all their lives making less than 25%, or less, of their potential HP. IMHO, nobody makes a street/track engine that will survive track use. BUT a track use built engine will be very happy on the street if the compression ratio and cam timing are carefully considered.

So what to do? Crate engines are a great way to get all the parts in one box. The crate 535HP LS chevy is just about right as far as hp goes and comes with a controller and associated parts that seem to work for most people. If I was doing this again I might just do that except take it apart and send the rotating assembly and block to my chosen shop to get it balanced, prepared, and reassembled with ARP rod bolts, While it was apart I would have the heads looked at, a really nice valve job done, some port cleanup and valve springs checked.

Now you have a motor that will run like a top for the car's lifetime.

Of course, you can do all this yourself and build a monster motor. Just be SURE you have someone who can tune it for you. I have been on record here for years taking the position that 500HP is plenty (maybe too much) for a 2500ish pound streetcar. Of course, it's your money so you are free to do whatever turns your crank.

That's my 2cents worth.

Engine Balancing: Achieve smooth performance & reliability. Learn the importance & tips for balancing various engine types.

www.enginebuildermag.com