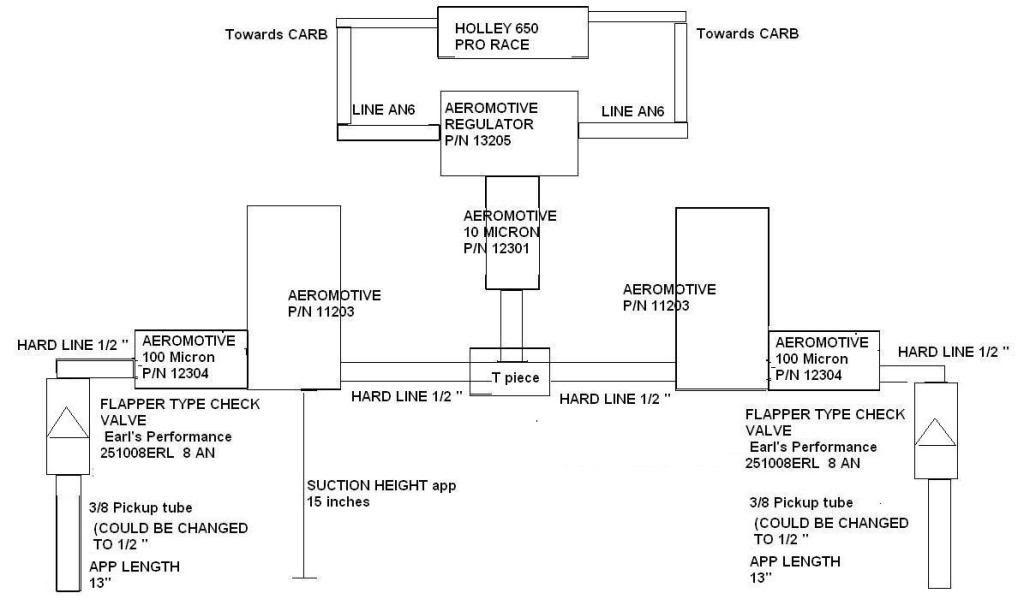

I am looking to start plumbing up the fuel system. I am running EFI. I currently have twin pumps and a solenoid operated selector. Other than staring at the chassis and unboxing the sending units that came from RCR, I have not done anything. I am not running fuel cells or foam, just regular tanks.

I am concerned about surging and running the pumps dry. I know this can be a problem. Many have done a surge tank, often with lower pressure pumps supplying the surge tank.

Any recommendations?

Also, crazy though it sounds, the whole make your own fuel system thing is new to me. Each tank needs a breather/check valve, correct? That should give you an idea of the intellectual level I am on. Scary, eh?

I am concerned about surging and running the pumps dry. I know this can be a problem. Many have done a surge tank, often with lower pressure pumps supplying the surge tank.

Any recommendations?

Also, crazy though it sounds, the whole make your own fuel system thing is new to me. Each tank needs a breather/check valve, correct? That should give you an idea of the intellectual level I am on. Scary, eh?