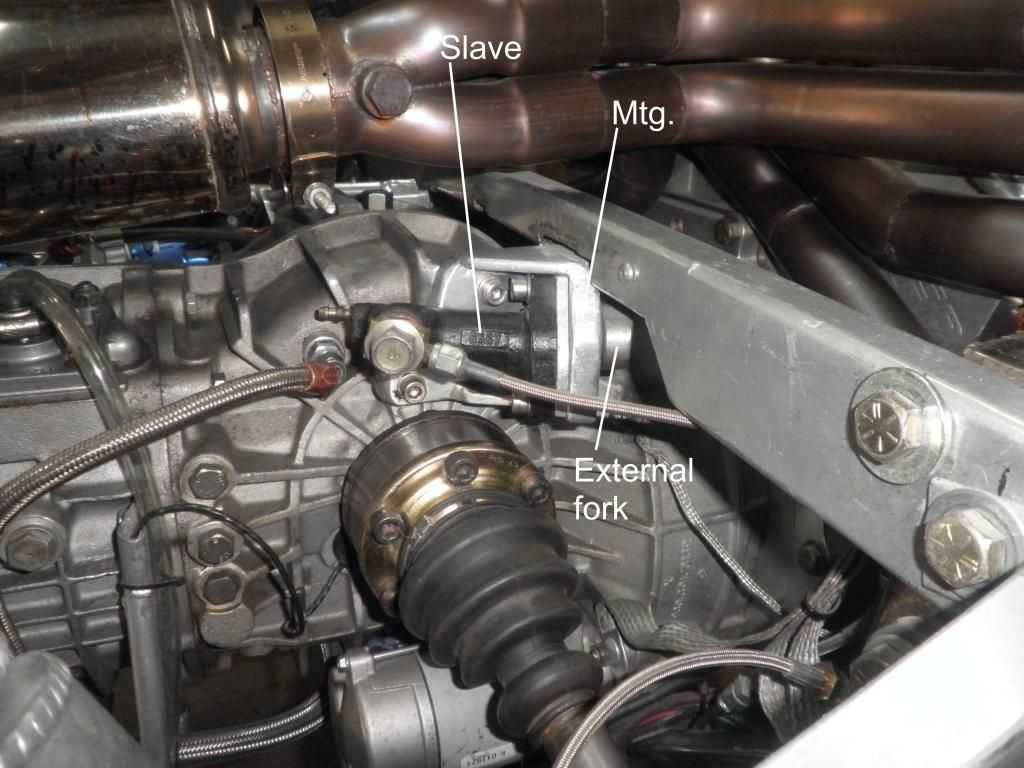

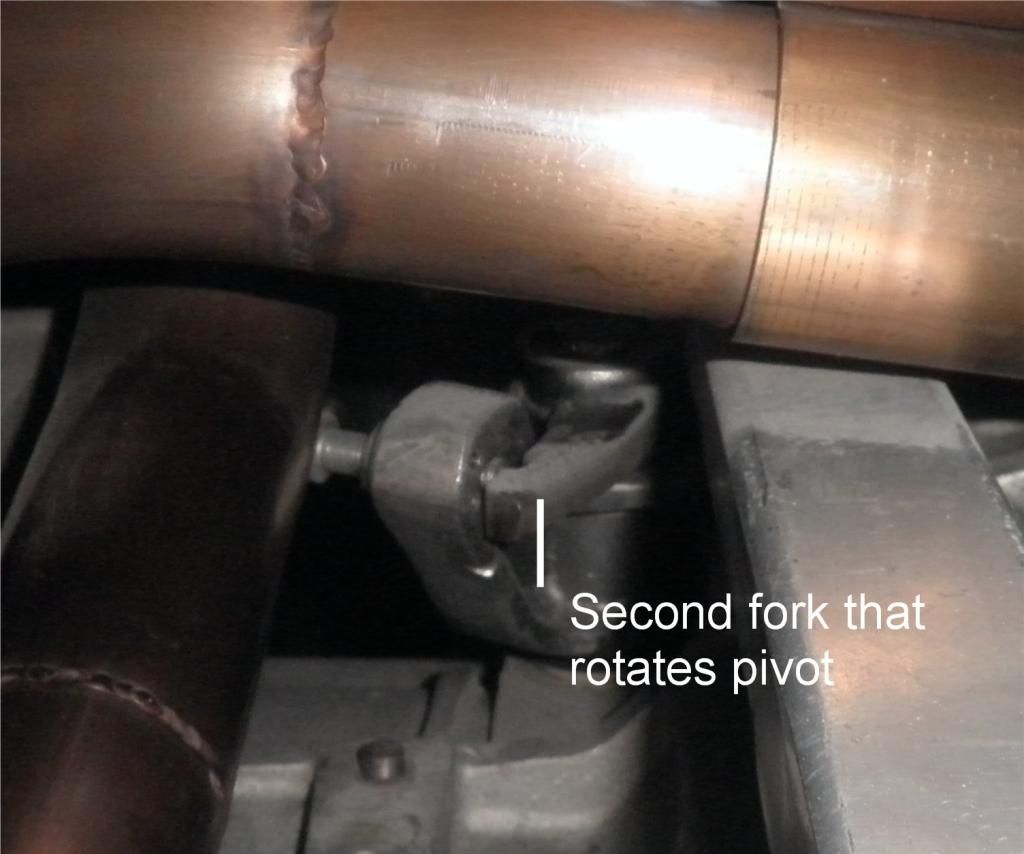

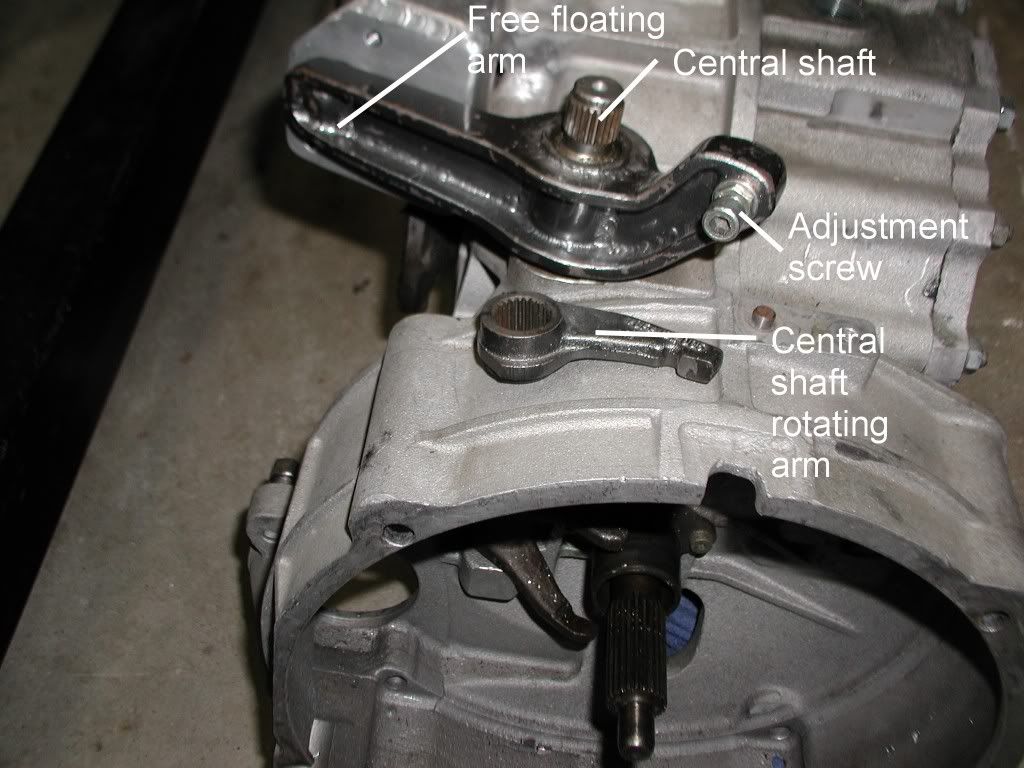

I have an issue with a new installation, where pushing the clutch all the way causes the slave cylinder to push the end of the fork onto the back of the spinning clutch. This happens right at the end of the travel and the clutch works fine if I do not press all the way down. I have tried adjusting at the pedal end however it did not make any difference.

Gearbox is G50-01 with Porsche slave cylinder. Pedal box is Tilton on a RCR40 chassis. Master cylinder and Tilton pedals were provided as part of RCR kit.

One thought would be to create a pedal stop, however I have not read of anyone else needing to do this.

Any ideas on how to limit the travel of the slave cylinder?

Thanks

Colin

Gearbox is G50-01 with Porsche slave cylinder. Pedal box is Tilton on a RCR40 chassis. Master cylinder and Tilton pedals were provided as part of RCR kit.

One thought would be to create a pedal stop, however I have not read of anyone else needing to do this.

Any ideas on how to limit the travel of the slave cylinder?

Thanks

Colin