Hi

I´m using a complete new clutch setup . The idea was to depart from the 89 porsche turbo pressureplate as it was just build in that year. Another shortcome of it is that there are not many alternative (high performance) pressure plates. On top of that it is pretty expensive and quite heavy.

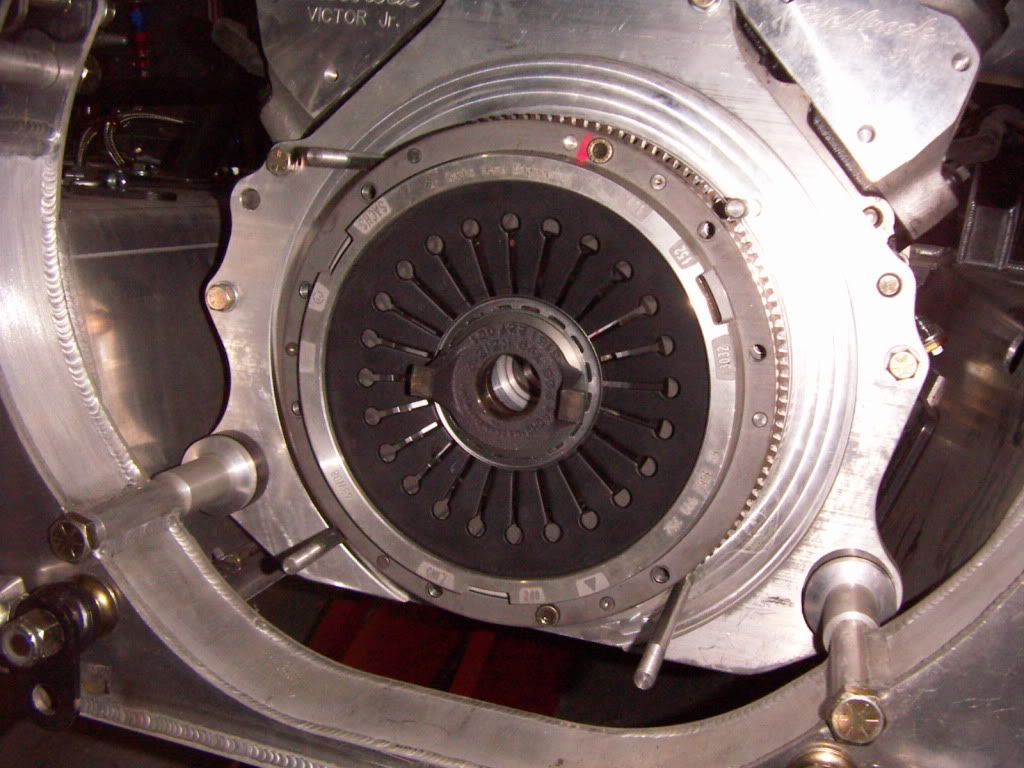

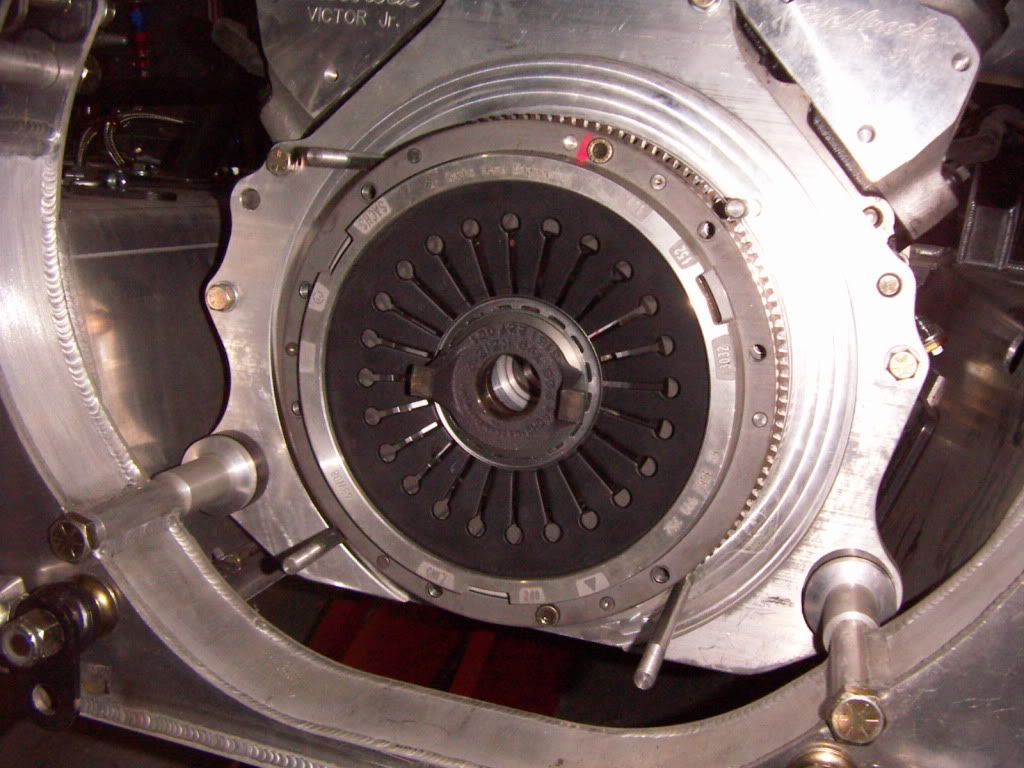

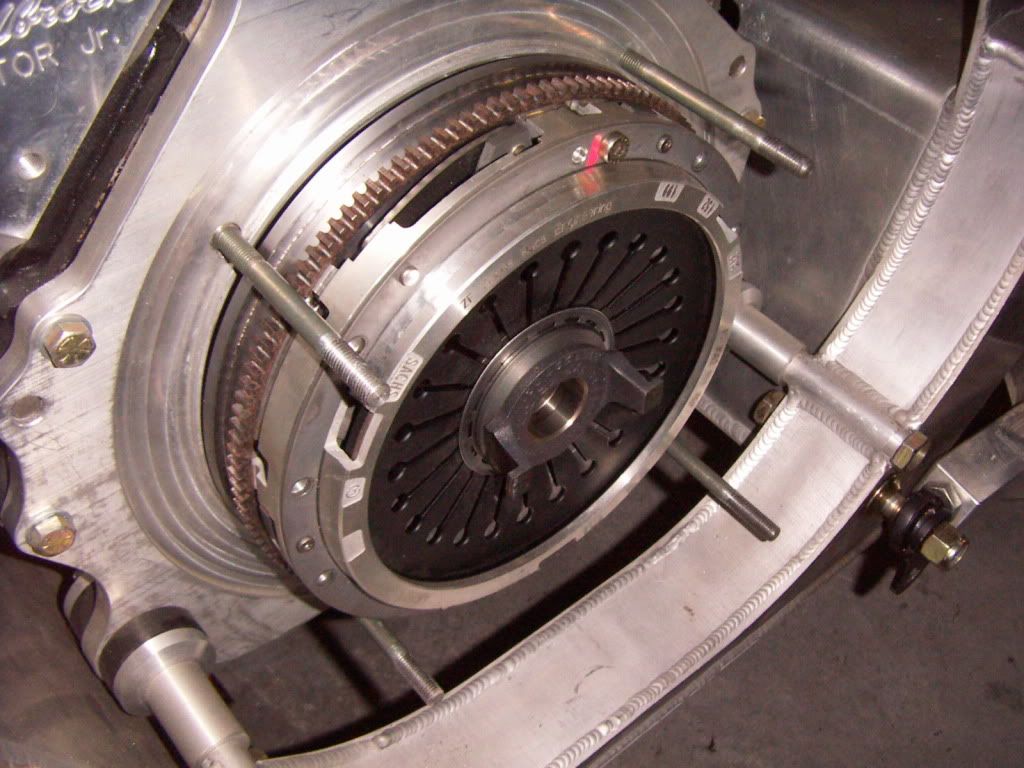

I´m now using a setup which utilizes the parts of Porsches GT2 and GT3 and RS series starting from the 964 up to the current 997 types. They all use the same dimension clutch components. The pressure plate is available in 3 different spring force choices ( stock, performance, high performance).

There are also five different frictionplates available. Everything is stock porsche or Sachs performance parts.

The different combinations give the option to go from 500 NM up to 1200 NM of torque capability.

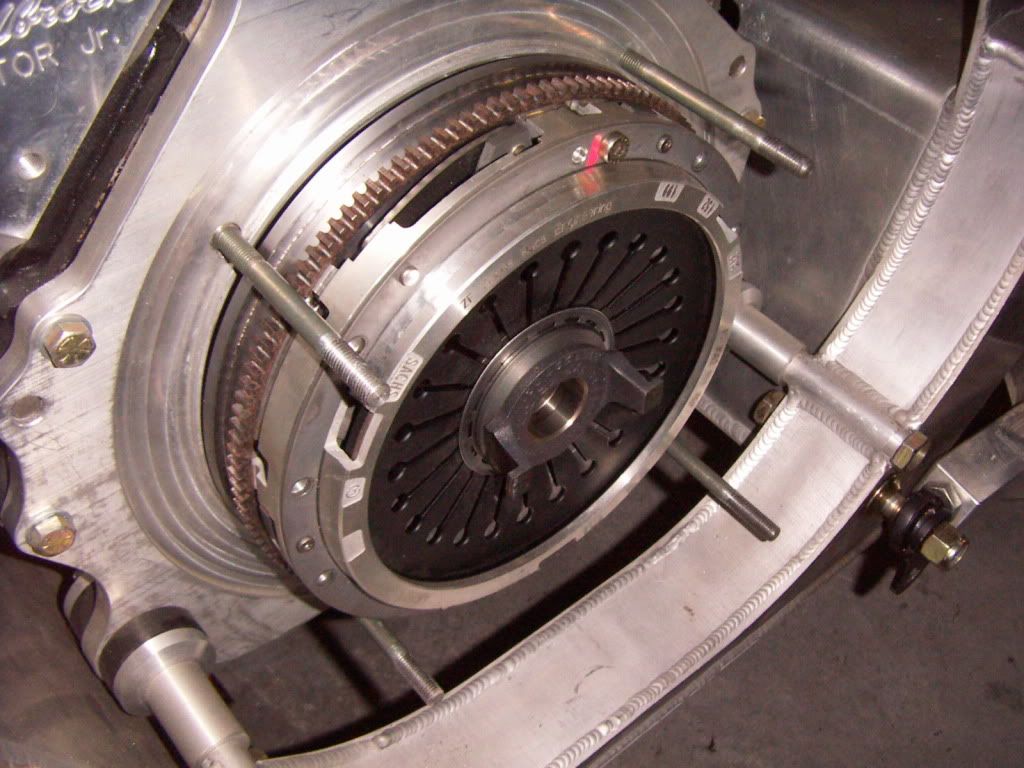

The whole assembly is app 4 lbs lighter than the usual KEP setups or setups using the original 89 turbo pressure plate. Of course i had to make up a specific flywheel for that. The combo fits G50, G96 ( for shure) and probably also 930 Transaxles.

A major difference is also that the ringgear is sandwiched inbetween the pressure plate and the flywheel ( standard porsche as of the 964). This results in a needed pinion depth of 82 mm which none of the usual gear reduction startes can provide. As already showed in Ron´s and Randy´s thread the stock starter can not be used when mounted the engine much more forward than the RCR reco, because the starter solenoid won´t clear the chassis.

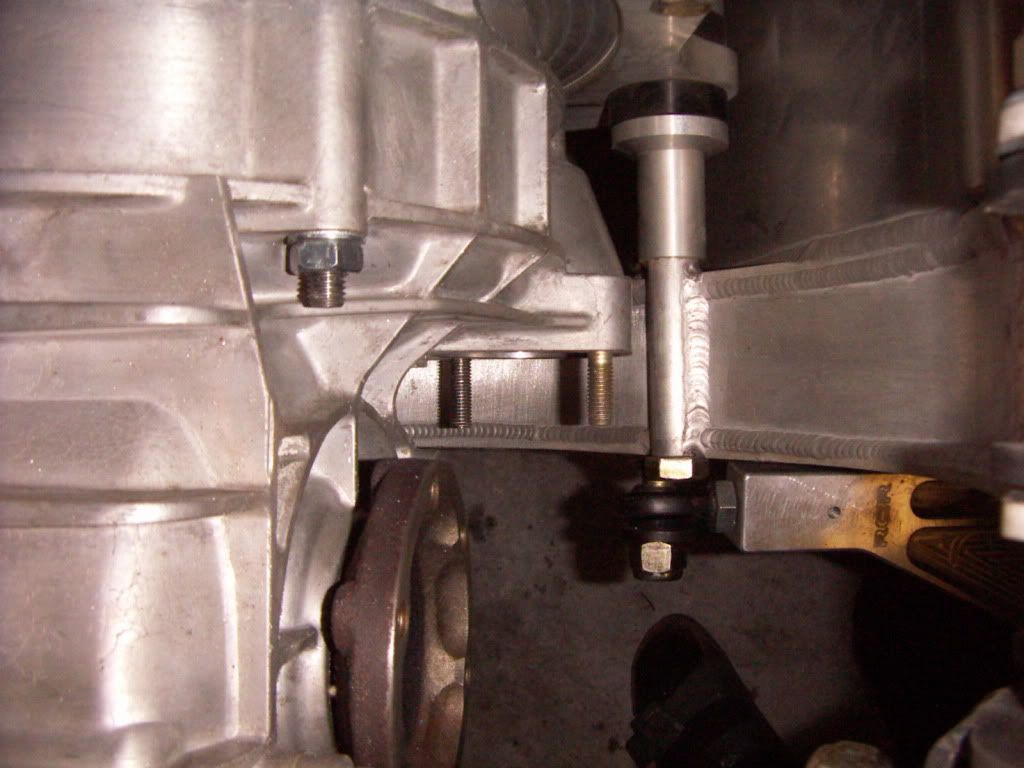

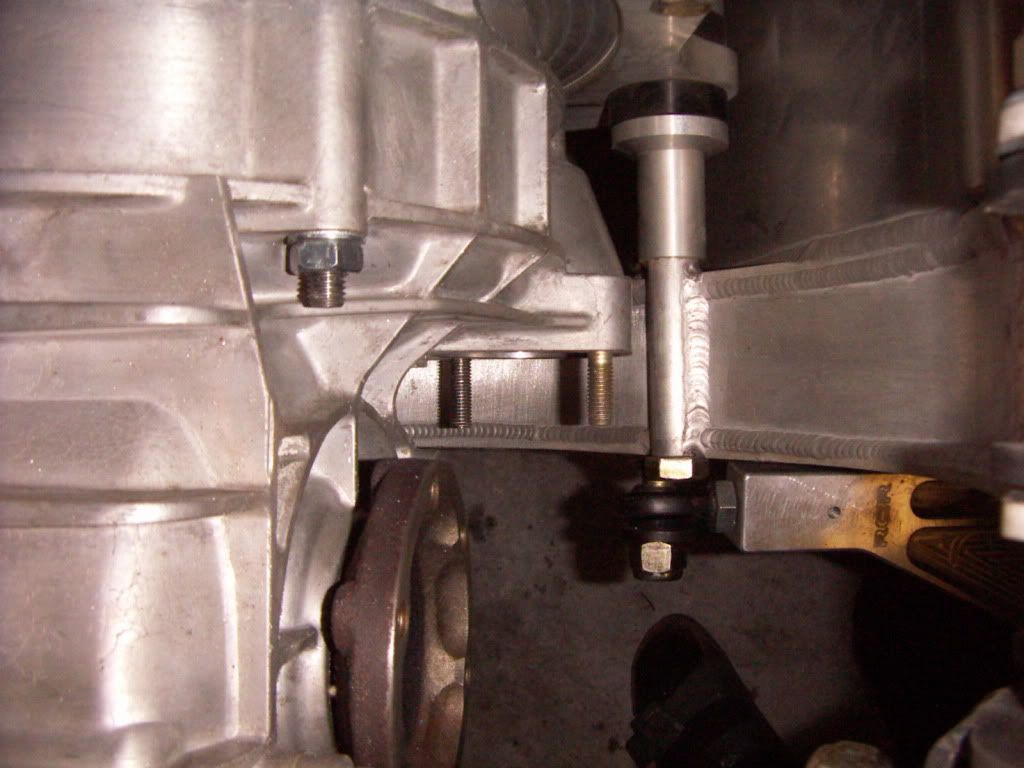

I have found a very innovative starter with a planetary gear reduction drive, 2 KW motor, the solenoid mounted behind the motor thus pushing the drive shaft. On top of it, it is very lightweight. The concept of this starter allows to mount it without any clearance issues, because it is nothing more than a cylinder. The starter has the correct pinion depth.

for calculation of the clutch master and slave cylinder i did the attached calculation sheet. best solution so far seems to be the stock porsche slave and a 3/4 inch master. There is also a CNC milled slave available from MPL which has a bigger piston, thus reducing the pedal forces.

I will start with the stock one and see how it is.

The excel chart could be used on every clutch setup as long you know and change the yellow fields.

If one is itterating to the max release bearing travel you could also calculate the clutch stop dimension needed.

looking forward to test this assembly in summer

TOM

I´m using a complete new clutch setup . The idea was to depart from the 89 porsche turbo pressureplate as it was just build in that year. Another shortcome of it is that there are not many alternative (high performance) pressure plates. On top of that it is pretty expensive and quite heavy.

I´m now using a setup which utilizes the parts of Porsches GT2 and GT3 and RS series starting from the 964 up to the current 997 types. They all use the same dimension clutch components. The pressure plate is available in 3 different spring force choices ( stock, performance, high performance).

There are also five different frictionplates available. Everything is stock porsche or Sachs performance parts.

The different combinations give the option to go from 500 NM up to 1200 NM of torque capability.

The whole assembly is app 4 lbs lighter than the usual KEP setups or setups using the original 89 turbo pressure plate. Of course i had to make up a specific flywheel for that. The combo fits G50, G96 ( for shure) and probably also 930 Transaxles.

A major difference is also that the ringgear is sandwiched inbetween the pressure plate and the flywheel ( standard porsche as of the 964). This results in a needed pinion depth of 82 mm which none of the usual gear reduction startes can provide. As already showed in Ron´s and Randy´s thread the stock starter can not be used when mounted the engine much more forward than the RCR reco, because the starter solenoid won´t clear the chassis.

I have found a very innovative starter with a planetary gear reduction drive, 2 KW motor, the solenoid mounted behind the motor thus pushing the drive shaft. On top of it, it is very lightweight. The concept of this starter allows to mount it without any clearance issues, because it is nothing more than a cylinder. The starter has the correct pinion depth.

for calculation of the clutch master and slave cylinder i did the attached calculation sheet. best solution so far seems to be the stock porsche slave and a 3/4 inch master. There is also a CNC milled slave available from MPL which has a bigger piston, thus reducing the pedal forces.

I will start with the stock one and see how it is.

The excel chart could be used on every clutch setup as long you know and change the yellow fields.

If one is itterating to the max release bearing travel you could also calculate the clutch stop dimension needed.

looking forward to test this assembly in summer

TOM

Attachments

Last edited: