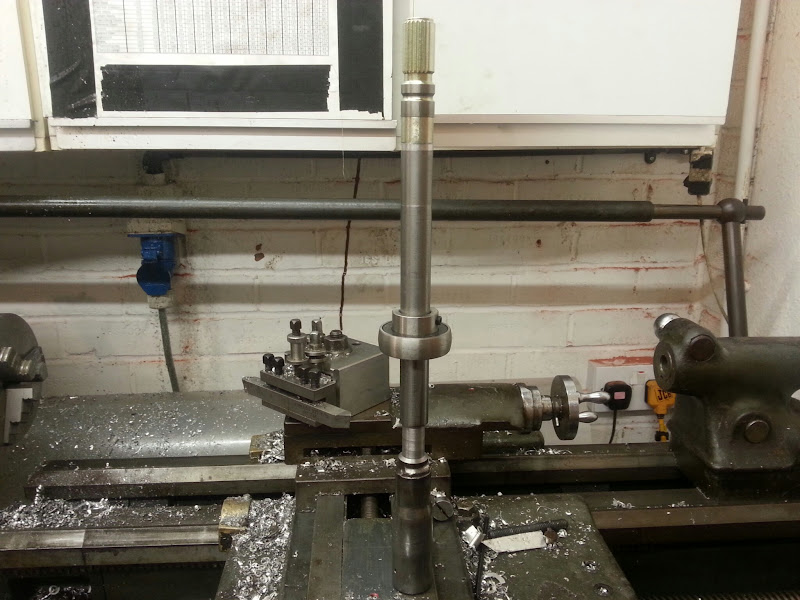

Just fitted a Corsa C EPAS column in the '40, the top of the column has a 22.5mm splined (male) shaft. I want to fit a steering wheel quick release sleeve to this. The sleeve I have has hex head (about 1.5" across the flats) that locates into the steering wheel, and has an internal hole diameter of about 20mm, that mated with the previous column. So I may have to get a new hex sleeve made to fit the steering wheel and mate with the column. I have a couple of options:-

1) get new sleeve made with a hole 22.5mm diameter (no splines) that simply slips over the shaft of the column and then roll pin (x2) that in place. Question, would roll pins be a good idea in this scenario? I'm worried about the roll pins gradually closing through time and failing.

2) do I go the whole hog and get new sleeve made with 22.5mm diameter internal splines that simply slips over the shaft of the column and then roll pit that in place?

3) source something that natively mates with 22.5mm splines?

Any advise welcome,..... no old jokes about steering nuts. K

1) get new sleeve made with a hole 22.5mm diameter (no splines) that simply slips over the shaft of the column and then roll pin (x2) that in place. Question, would roll pins be a good idea in this scenario? I'm worried about the roll pins gradually closing through time and failing.

2) do I go the whole hog and get new sleeve made with 22.5mm diameter internal splines that simply slips over the shaft of the column and then roll pit that in place?

3) source something that natively mates with 22.5mm splines?

Any advise welcome,..... no old jokes about steering nuts. K