Scott

Lifetime Supporter

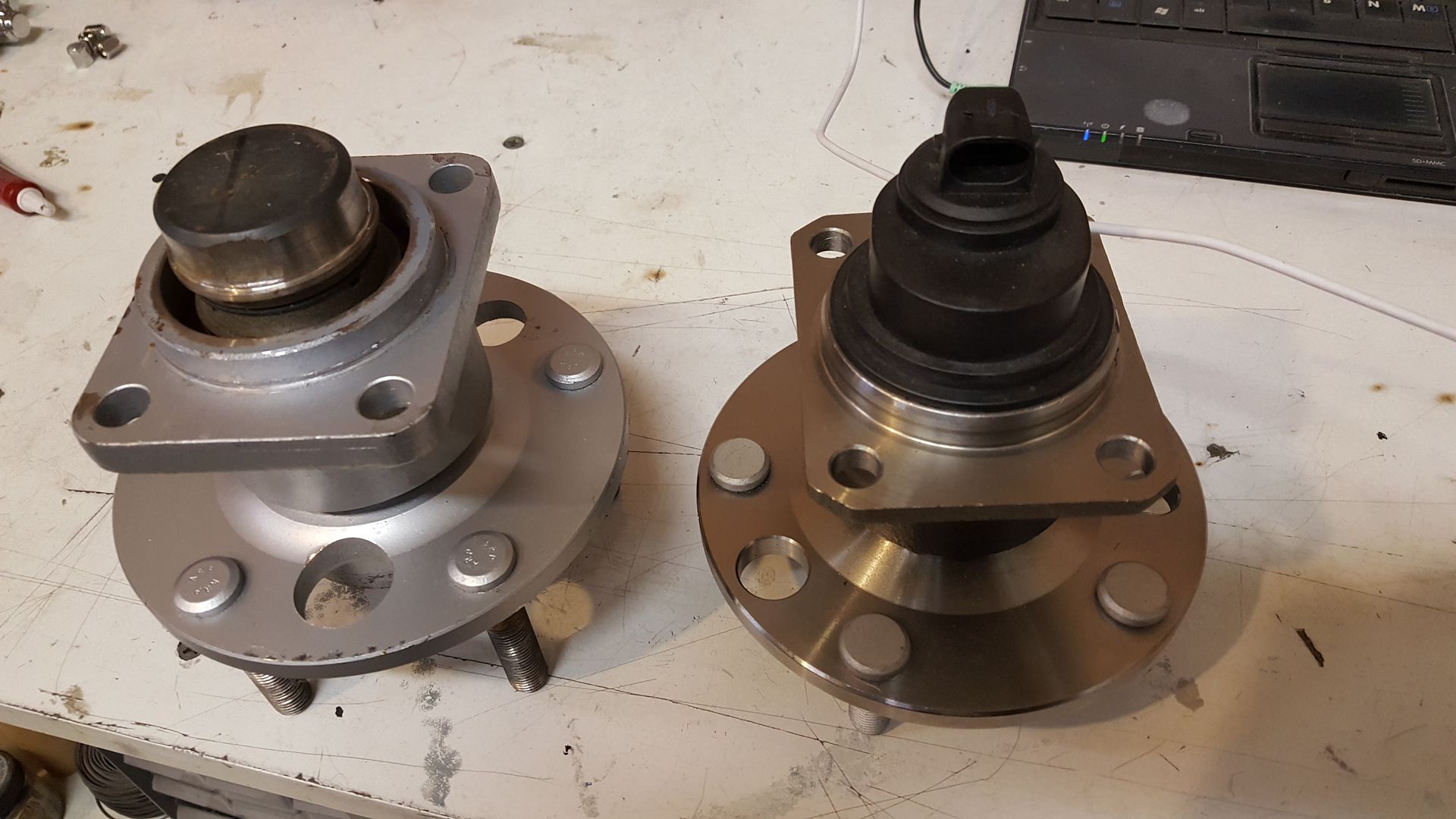

In looking at the ball joints today I noticed that one had a zerk fitting and that the other three were just open to the elements. If you haven't already done so, you should check that the fittings are in place.

The manual is mute on the topic (we can fix that)... are you greasing the ball joints and if so what type of grease are you using?

The manual is mute on the topic (we can fix that)... are you greasing the ball joints and if so what type of grease are you using?