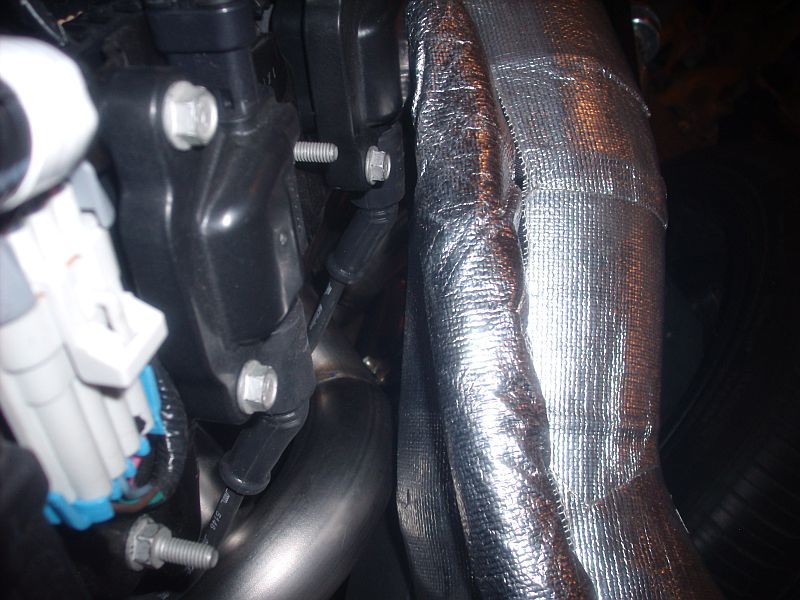

My air intake tube is pretty farkin close to the headers (it is what it is due to body fitment and equal length headers). About 1 finger width away.

I've wrapped it in 2 layers of thermotec adhessive heat barrier to try to minimize heat soak while idling.

I'm kind of limited as to what I can use to reflect heat because it's close to the headers (so can't be loose anywhere near there) and also can't be very thick (because it comes like 1/8'' away from the body), so usual theory of as many layers as possible is limited here.

I don't think there's much else I can do? The only other thing I can think of is running some flexible ducting from the side scoop and point it at that area, but I don't think that will accomplish anything (at speed it will be cool anyways, at idle it won't do any good)

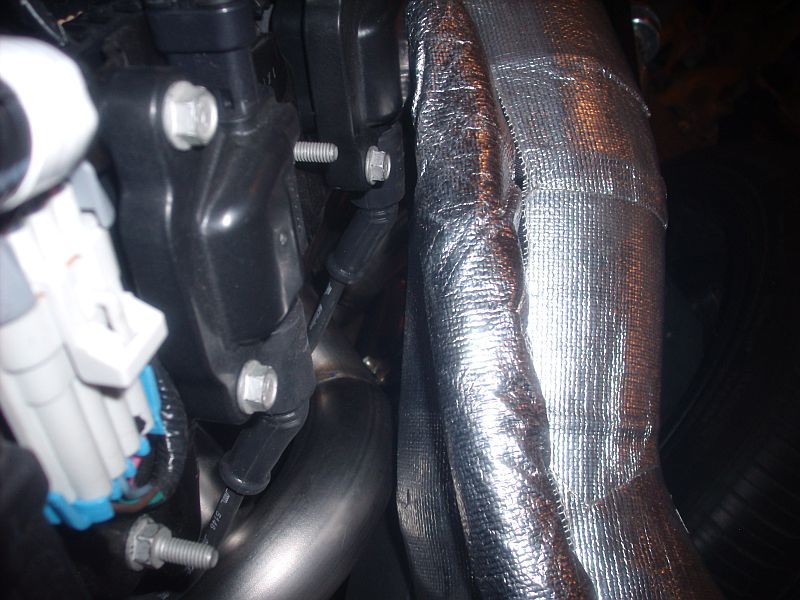

I've wrapped it in 2 layers of thermotec adhessive heat barrier to try to minimize heat soak while idling.

I'm kind of limited as to what I can use to reflect heat because it's close to the headers (so can't be loose anywhere near there) and also can't be very thick (because it comes like 1/8'' away from the body), so usual theory of as many layers as possible is limited here.

I don't think there's much else I can do? The only other thing I can think of is running some flexible ducting from the side scoop and point it at that area, but I don't think that will accomplish anything (at speed it will be cool anyways, at idle it won't do any good)