Having finished the X-pipe and oil inlet heatshields, the starter heatshield was next. However, when I went to install the starter, it collided with the catalytic converter.

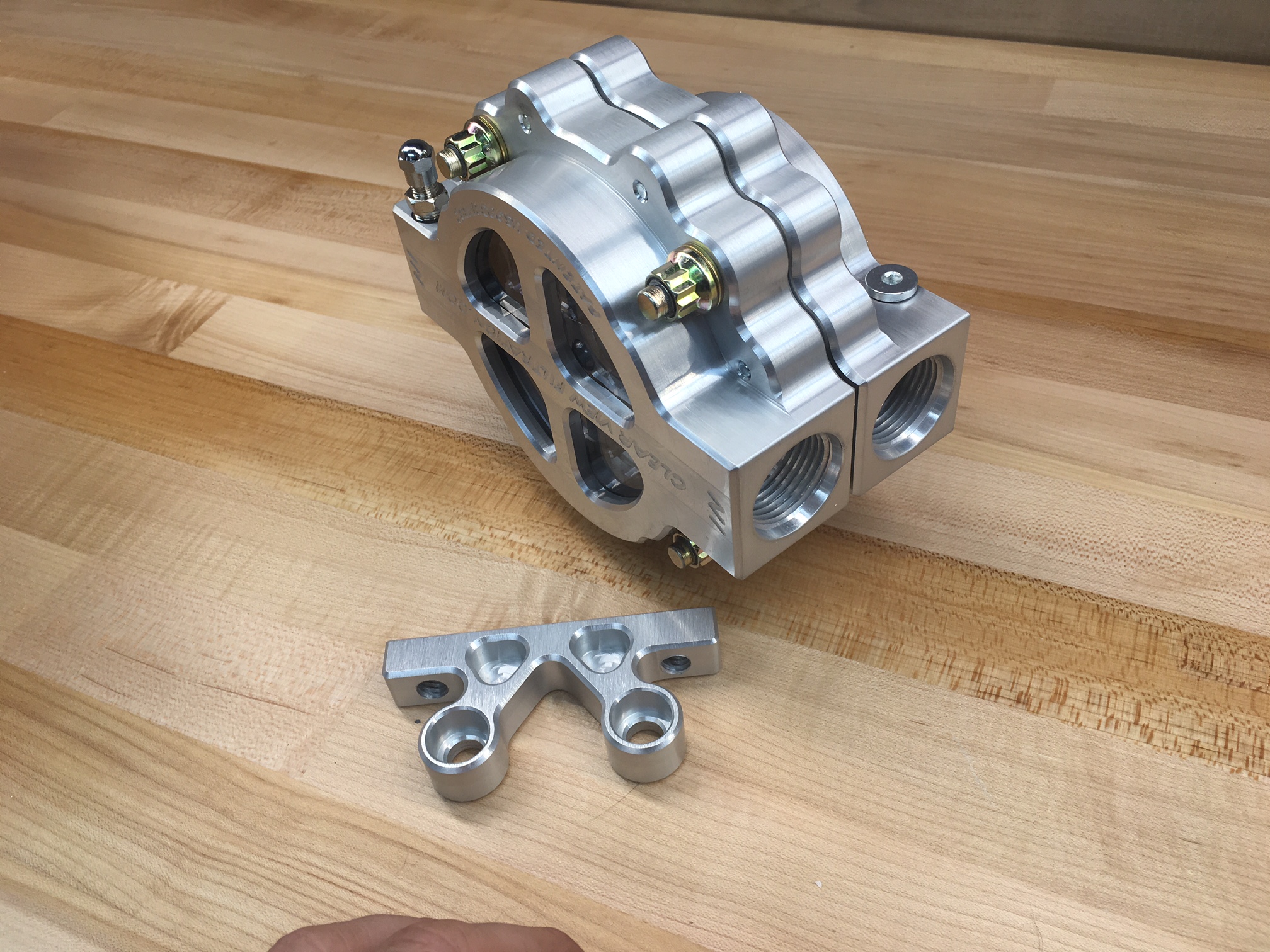

How the F did that happen? Not the first time that something was overlooked because I didn’t have all of the relevant parts in place when making decisions. In a previous post I used a rotary table to machine the starter’s mounting flange to clock the starter to its maximum, so I thought I was screwed. The only solution would be to machine the starter’s gear reduction housing which, if possible, would result in the top bolt being captured between the mounting flange and the housing. Not ideal, but workable. So, I popped the starter apart and determined that I was in luck. There are isolated cavities on the left and right of the cavity that contains the gears. This allowed me to machine a notch for the captured bolt (the problem at hand) as well as drill and tap a hole to support the heat shield. Once that was done, I repeated the process of machining the mounting flange to further clock the starter as described in t

his post.

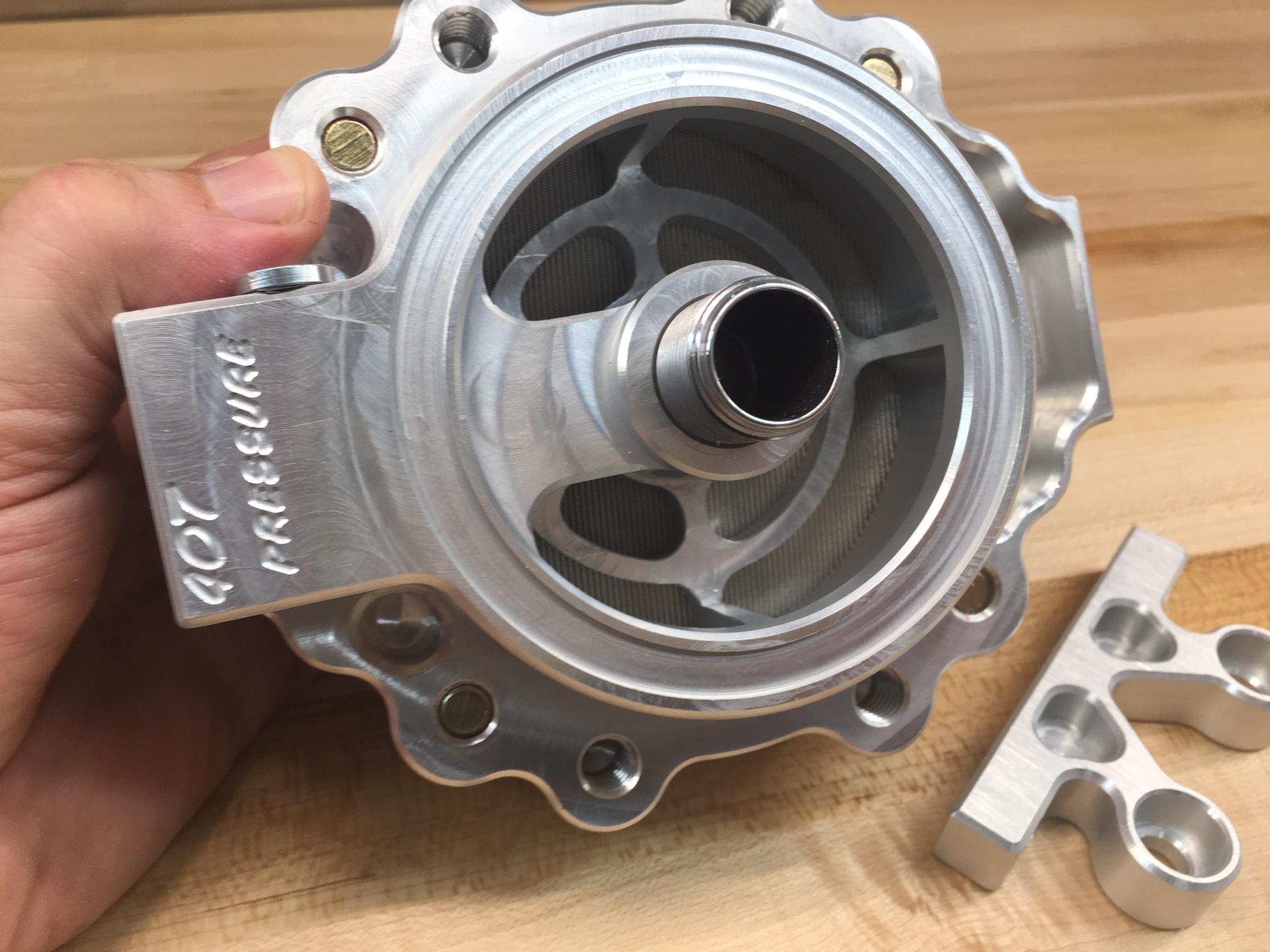

The cavity on the right will be notched to accommodate the head of the captured bolt and the cavity on the left will be drilled and tapped to provide support for the heat shield

While the starter/catalytic converter collision was a very unpleasant surprise, the reality is that I would have wound up in the same place even if I had noticed the issue before fabricating the cat-back system. That said, you really want to know that you can get out of a hole BEFORE you fall into it.

As is typical in a SL-C, everything was really tight and it took me a while to figure out how to design the heat shield. Part of the challenge is that the mounting flange is cantilevered at a 15-degree angle resulting in the assembly constantly falling over while I was that trying to take measurements. After much frustration, it occurred to me to 3D print a jig to hold it at the correct angle… yeah, that made a big difference.

Starter mounted to a 3D-printed jig (top), miscellaneous scrap shims (left), feeler gauge (center), digital angle finder (right) and mock 3D-printed bend profile (top right). Note the modifications to the starter; a notch has been machined into the top to accommodate the captured bolt and a hole has been tapped on the right side to support the heat shield.

I have found the following useful when measuring awkward items. Scrap shims of various thicknesses combined with a feeler gauge. Just make sure that you debur the edges of the shims so that they sit flat. A digital angle finder is also very useful — Abe has a manual one, but he borrows my digital one a lot. It measures to one tenth of a degree and there are buttons to zero it and to display the reverse angle which means that you don’t need to do any math. It’s well worth the $16. I also 3D printed narrow sections of the bend profiles to fine tune clearances. For example, the thin black piece in the upper right of the picture above is the profile of the main shield and a welded mounting arm.

Like the other heat shields, this one required me to learn a few more sheet metal tricks:

Tutorial:

I spent a little over two hours watching a tutorial on Solidworks sheet metal features; 80% I knew, 10% showed me how to do certain things better, 5% was completely new and 5% was irrelevant to my use case. The high-end CAD packages have a lot of advanced features and it’s worth spending a little time and money to access quality online training.

Unfold and Fold Features:

For the last two heat shields I was able to use Solidwork’s

Corner Relief feature to ensure that bending wouldn’t deform the corners. However, no matter what I tried, SendCutSend rejected several of the bends because it didn’t like several of the corner reliefs. The solution was to use the

Unfold feature to flatten the problem flanges, add extruded cuts to the problem corners, and then refold the flanges via the

Fold feature. Problem solved.

Closed Corner Feature:

Once the bend radius and K-factor are set for the type and thickness of material, the software automatically calculates the bend allowances which is great. However, I had several areas where after making several bends the material bent back onto itself and I wanted to ensure that the gap was tight enough to be welded. Fortunately, Solidworks has a

Closed Corner feature that does exactly that. You simply click on the two edges that you’d like to “close,” specify the desired distance between those edges, and then choose one of three options; (1) butted, (2) edge A overlapping edge B or (3) edge B overlapping edge A. SendCutSend specifies 15 thousands as the minimum tolerance which worked out great.

In the picture below, the feature is closing the corner between the two blue edges. The yellow part showing how one of the flanges is being extended. The second flange remains unchanged because I had specifically trimmed it in a previous step, but in many cases both sides are extended. You can also see the left most (i.e., butted) of the three options is selected and that the distance is 15 thousands of an inch.

It would be extremely difficult to figure out all of the bend allowances and closed corners without CAD. The curved line on the right is the final shape, but that flange was extended to provide a parallel edge to the bending line allowing it to be pushed in the CNC back stop. If you look closely, there are small bridges on the curved portion to facilitate removal post bending.

Multi-Body Part:

I have been aware of the multi-body feature for years, but I never used it. My workflow was to design separate parts and combine them into an assembly to ensure that everything fit. This works, but you have to update the relevant dimensions in multiple files and you have to mate everything in the assembly. I have used external global variable files before, but that takes a little effort.

With a multi-body part, you basically design other parts in the same file. This allows those parts to be parametrically driven by the first part. There is no need to update the dimensions in multiple files, no need for an external global variable file, and no need to mate the parts in an assembly. I wouldn’t do this with all of my parts, but in the right situation it really simplifies workflow.

Part too Small:

One of the parts was rejected by SendCutSend because it didn’t meet the minimum size for bending. The solution was to extend the part to meet the minimum size and to add bridges to make it easy to remove the excess post bending.

The heatshield involved four laser-cut pieces, one hand-cut piece, ten CNC bends and two spacers fabricated on the lathe. The bends were perfect, but when I went to install it I didn’t have as much clearance as I wanted, so I cut a 45-degree corner into the bend with the red line below and then welded a piece into the gap.

The heatshield is solidly mounted at three points; the arm that connects to the lower flange bolt, the tapped screw in the front face of the starter’s casting, and the tab (purple) that was added to the long bolt in the back of the starter. It is solid enough that the assembly can be lifted by the heat shield.

The starter was easy to take apart, but I couldn’t reassemble because it needs to be compressed. So, I took it to a repair shop. When, I decided to add a mounting tab to the rear bolt the starter’s halves separated on that side and I couldn’t get it back together. So, I made a second trip to the repair shop. If you’re going to remove that bolt, ensure that you tightly clamp the starter in a vice before doing so.

Heatshield (left) and starter (right). The arrow points to the rear mounting tab and spacer. You need to clamp the starter when loosening the long bolt to install the rear tab or you’ll be visiting the repair shop to get things put back together.

Three heat shields down, nine more to go.