- Forums

- GT40 Replica Manufacturers' Corner

- RCR Forum - RCR40/SLC/917/Superlite Aero

- The SLC Clubhouse

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SLC Build Thread-Chassis #53

- Thread starter Stage7

- Start date

Maybe I am not seeing the whole concept ? but wouldn't running the exhaust straight back into itself create a Sh*t load of back pressure ?

I don't think it would be any different than a standard H-pipe?

Maybe I am not seeing the whole concept ? but wouldn't running the exhaust straight back into itself create a Sh*t load of back pressure ?

I had the same question pop in my mind when I was designing it in my head. Then I remembered that fluids always flow the path of least resistance...so I built it. My crude compressed air test after it support's it shouldn't be a problem.

The proof will be on the dyno when I test it with open headers vs. the catback. If it's much more than a 2-3% difference, I will first cut out the cats and test it again. If the drop is still there, that will leave the overall design in question as I doubt the mufflers will be a problem.

I don't think it would be any different than a standard H-pipe?

H pipe is still at a 90 to the direct exhaust flow so the blow-by will pull the exhaust out, X work best because the air of both tubes are moving in the same direction works like a vacume drawning from each other. Even a big headed bolt on the inside of the tube will give you quite a bit of back pressure not just from the bolt itself but from the turbulance it creates.

Having a balance tube or cross over turn straight back in on itself is going to creat a Sh*t load of back pressure, you may gain some bottom end torque at low speeded, but top end HP will suffer big time when you open it up. A third tube out from the middle of the crossover would tame this down going back in the same direction as the exiting exhaust but no room for that. Any ways this will be very interesting to see what happens !

I will keeping my eyes on this one, RM please keeps us up on your findings.

Hope it all works out well for you.

I had the same question pop in my mind when I was designing it in my head. Then I remembered that fluids always flow the path of least resistance...so I built it. My crude compressed air test after it support's it shouldn't be a problem.

The proof will be on the dyno when I test it with open headers vs. the catback. If it's much more than a 2-3% difference, I will first cut out the cats and test it again. If the drop is still there, that will leave the overall design in question as I doubt the mufflers will be a problem.

The exhaust side of an engine is a big ass air compressor, air can become very solid when under pressure. Just to be on the safe side when you test this design you may want to build in wastegates close to the engine in case your exhaust loads your cylinders up more then connecting rods or pistons can take specially if you have hyperutictic pistons this could be

catastrophic. it always better to error on the side of caution.

Cheers.

Grant,

I appreciate your concern, but I don't know if I agree with the doomsday scenario. fwiw, the engine is fully forged.

Whether or not it is optimal will show itself. I'm not making any proclamations either way. I haven't seen a design like this before, so I don't know how it will work, or sound.

I already have a x-pipe design figured out too and I am building one with no cats for off road track driving. That will be another point of reference. I'm doing the different configurations to experiment and test. I'm building a couple other sets of headers and exhausts for people so they will get the design that works the best in the end. My car/exhaust system is the mule.

Before it ever sees the dyno, it will have 2 back pressure gauges in the 2nd set of o2 bungs right when it's started so no need for a wastegate. If it looks ugly revving a little in neutral, it's coming off.

btw, x-pipes are not *always* superior to h-pipes in different combo's/cars. Not always in sound or performance. They usually are though, especially in cars with sub-optimal collectors and extra long catbacks.

I appreciate your concern, but I don't know if I agree with the doomsday scenario. fwiw, the engine is fully forged.

Whether or not it is optimal will show itself. I'm not making any proclamations either way. I haven't seen a design like this before, so I don't know how it will work, or sound.

I already have a x-pipe design figured out too and I am building one with no cats for off road track driving. That will be another point of reference. I'm doing the different configurations to experiment and test. I'm building a couple other sets of headers and exhausts for people so they will get the design that works the best in the end. My car/exhaust system is the mule.

Before it ever sees the dyno, it will have 2 back pressure gauges in the 2nd set of o2 bungs right when it's started so no need for a wastegate. If it looks ugly revving a little in neutral, it's coming off.

btw, x-pipes are not *always* superior to h-pipes in different combo's/cars. Not always in sound or performance. They usually are though, especially in cars with sub-optimal collectors and extra long catbacks.

Last edited:

Grant,

I appreciate your concern, but I don't know if I agree with the doomsday scenario. fwiw, the engine is fully forged.

Whether or not it is optimal will show itself. I'm not making any proclamations either way. I haven't seen a design like this before, so I don't know how it will work, or sound.

I already have a x-pipe design figured out too and I am building one with no cats for off road track driving. That will be another point of reference. I'm doing the different configurations to experiment and test. I'm building a couple other sets of headers and exhausts for people so they will get the design that works the best in the end. My car/exhaust system is the mule.

Before it ever sees the dyno, it will have 2 back pressure gauges in the 2nd set of o2 bungs right when it's started so no need for a wastegate. If it looks ugly revving a little in neutral, it's coming off.

btw, x-pipes are not *always* superior to h-pipes in different combo's/cars. Not always in sound or performance. They usually are though, especially in cars with sub-optimal collectors and extra long catbacks.

The chances of taking out the engine is very extreme, it would take a

combination of issues to cause such a case to happen this is true,

It sounds like you've got a pretty good handle on it. Please keep us in the loop on this design, as it is very intriguing.

Cheers,

Grant

Last edited:

Ken Roberts

Supporter

I'm trying to find some mufflers for my upcoming build. Can you tell me about your selection Roberto. I will be using the LS7 headers and cats.

Hi Ken. I haven't decided which ones I'm using yet, but I have Dynomax Ultra Flows and Vibrant Ultra Quiet Resonators (which I would use as a muffler).

Hi Rm,

Are you able to post up some more pics of the cats and how it connects up to the headers? Plumbing the exhaust has been one of my big questions when planning this build. Thanks!

Are you able to post up some more pics of the cats and how it connects up to the headers? Plumbing the exhaust has been one of my big questions when planning this build. Thanks!

Thanks guys.

Zubin: best pix I have are here: http://www.gt40s.com/forum/slc-clubhouse/34136-slc-build-thread-chassis-53-a-6.html#post349244

and here: http://www.gt40s.com/forum/slc-clubhouse/34136-slc-build-thread-chassis-53-a-6.html#post349245

Grant: I do have plans for turbo setup, but there are other projects ahead of it.

Zubin: best pix I have are here: http://www.gt40s.com/forum/slc-clubhouse/34136-slc-build-thread-chassis-53-a-6.html#post349244

and here: http://www.gt40s.com/forum/slc-clubhouse/34136-slc-build-thread-chassis-53-a-6.html#post349245

Grant: I do have plans for turbo setup, but there are other projects ahead of it.

Thanks Roberto!

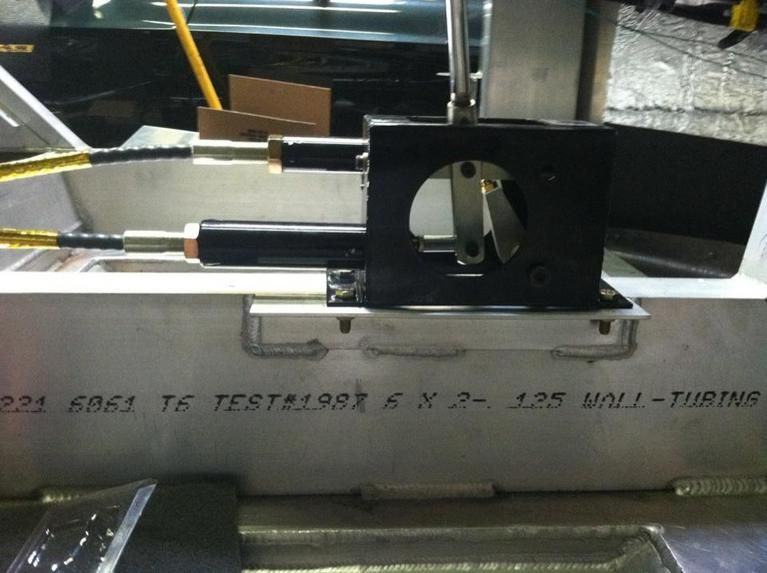

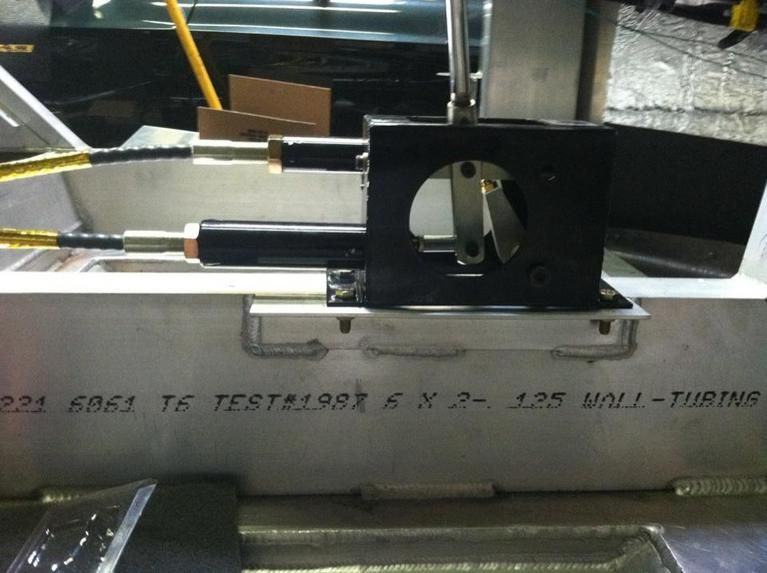

Custom brackets for throttle cable:

Bracket on. Relocating ops next:

Bracket on. Relocating ops next:

Last edited:

bracket for remote coils:

shifter mounted:

shifter mounted:

Last edited:

Evap mounted:

Steam vents fully routed:

Steam vents fully routed:

Mufflers on.