I continue having problems with the FAST XIM system. This system incorporates a crank trigger(set at 50º BTDC) and a cam sensor(set at 10-40º before the crank trigger signal) to determine the crank shaft position and the signal that TDC for the #1 cylinder is coming up in 50º. This is simple enough to understand. The problem has been there since about day 1, since the engine has been fired up. There continues to be backfiring up through the injectors, jerky sounding starter, flames up through the injectors and 4 sets of ring gears with missing teeth. The engine will fire up and runs great once running, as seen in the videos I have posted. We have tried almost everything to correct the issue. I had reached the point where I wanted to go with a standard distributor(MSD). The issue is a timing problem. The teeth were knocked off by the engine trying to turn backwards from the backfiring. I realized that the experts that have helped missed the boat with initial timing of the engine. The first expert could not get the crank trigger to be set at 50º, so he set the computer to 46º to compensate(didn't set the crank trigger properly). The second expert told me I had to get the trigger to 50º and set the computer inital timing to20º. The rpm settings in the software start at 400(cranking) then 900(idle). I altered the crank trigger to reach the 50º setting by adding an aluminum extension to the mounting bracket. More about that later. Trying to get it to start with the new info and pieces resulted in the fourth ring gear breaking teeth after only two attempts at starting. I studied all of the MSD videos and they described my problem to a T. It was a "rotor phasing" problem. How it was with this system I don't know as I have a magnetic sensor where the distributor is(cam sensor). One of the videos on timing discussed how for the small block Chevy the "normal" initial timing for cranking is set at 12º. They talked also about timing advancement as the rpms climb. At any rate a light went off in my head. I needed lower advancement(or retarding) of the timing for the cranking rpms(400). So I set the initial timing to 8-12º for the 400 rpm collum and 20º for idle working up to 32º at WOT. When the engine ran in the past it was set at 20º so nothing was changed. This time when I tried to start the motor, it spun faster as though it was flooded and was trying to start. There was some backfirng through the injectors but not as forceful or as loud. Previous backfires sounded like shotguns going off. This was now just a pop, but the motor just wouldn't start. The computer box has been sent back several times and declared in good working order. One of the earlier trips found a bad driver to one coil. It was repaired at no cost.

I had met a fellow at a car show who had a 351 like mine with 8 port injection but his ignition was an MSD and it started like a charm. He gave me a contact with the person who built his system. He was contacted and the car was taken to his shop. After 2 days of his checking things he noticed that the crankshaft would turn 6-10º before the distributor(cam sensor) would move. We believe it is timing chain stretch from all the backfiring, and the attempts to turn the engine backwards when this happened. He was going down to Daytona for the races (July 4th) as he is a member of one of the Nationwide pit crews and doubles as their tuner.

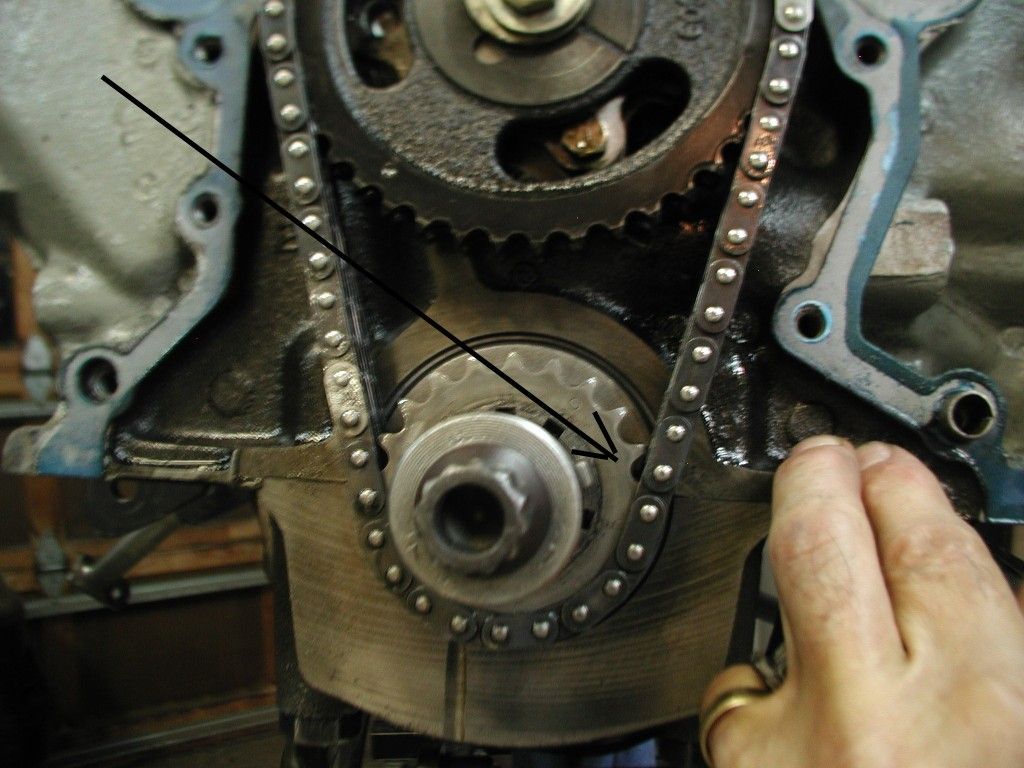

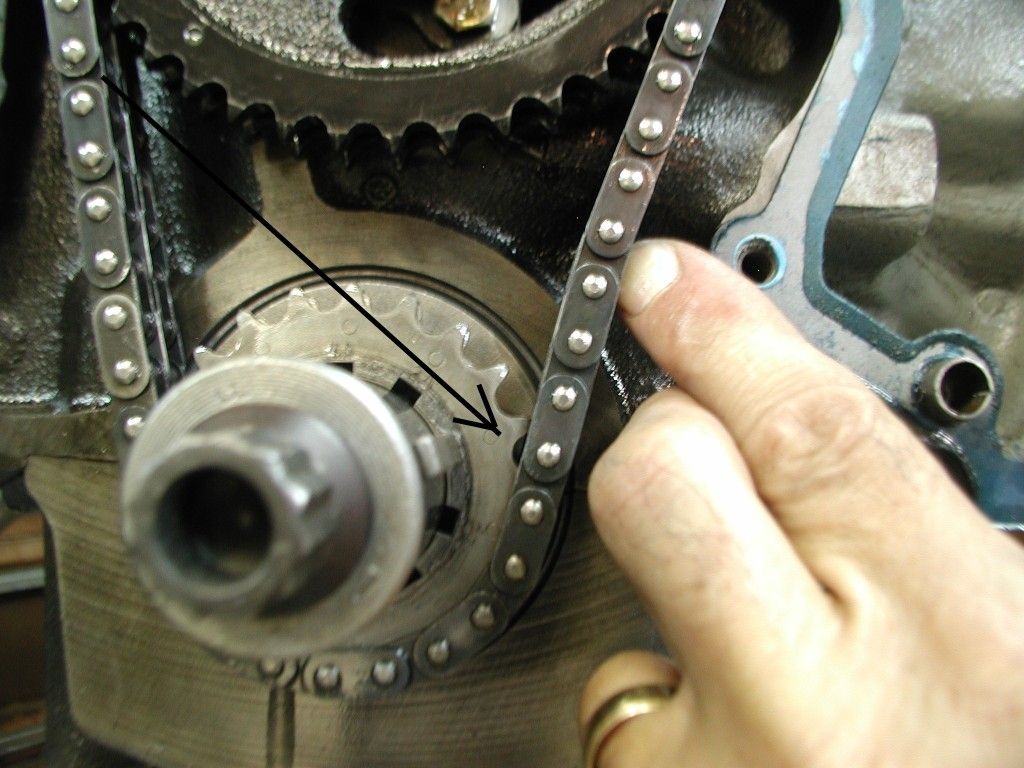

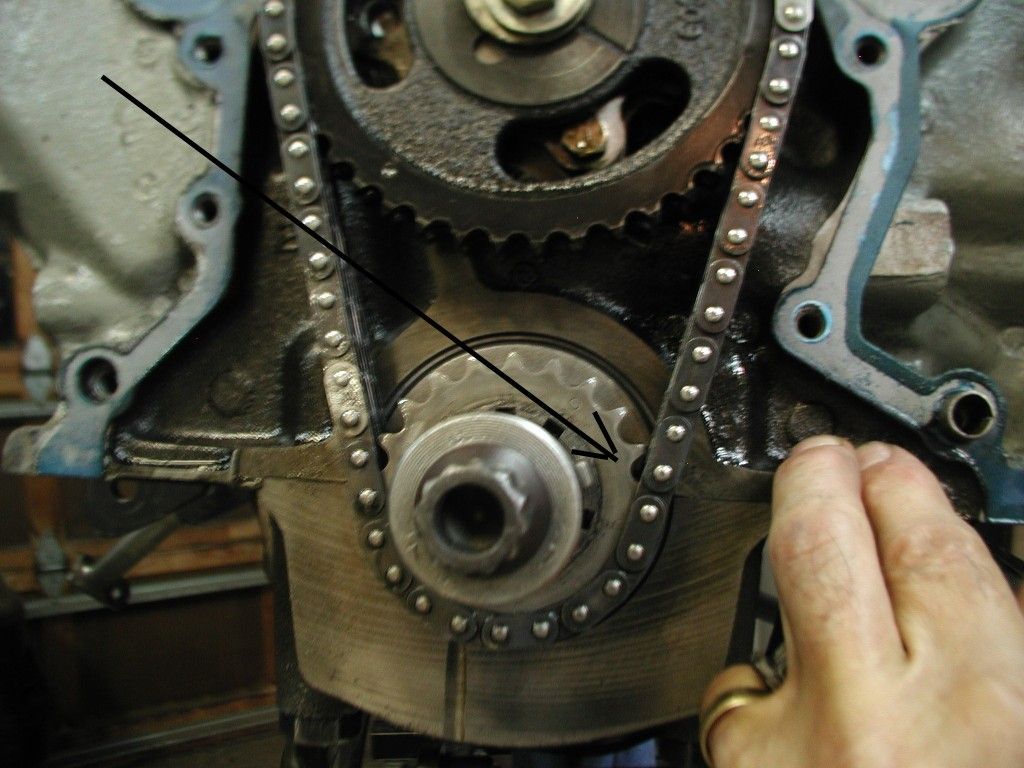

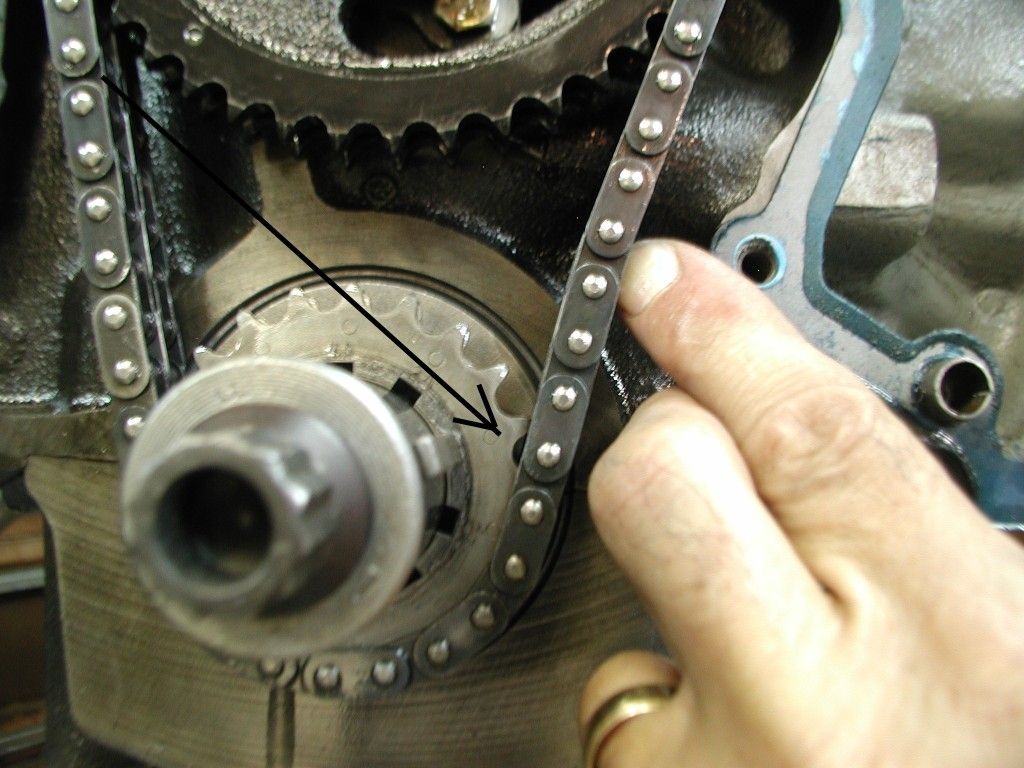

To save money and time, the car was brought home and the engine pulled. Inspection revealed the following. Notice the deflection and arrows.

I believe this introduced the rotor phasing I mentioned above and is retarding the timing even more so there is no real power stroke as firing is occurring on or about TDC. It still doesn't explain the backfiring up through the injectors though. Does this sound reasonable???

I have made the decision the go the MSD route and will install a new timing chain and either the digital 6AL-2, or the programmable unit as it will give me a rotor that will keep the fire on one cylinder at a time.

It was also discovered the crank trigger is an old one that has been altered(rounded out holes) so it can't be set to use the normal mounting holes as described in their video. It also has gouges out of the back of it. It isn't a new unit, and will be replaced.

Should the cam be "degreed in" or installed straight up? If degreed, should it be advanced or retarded? The car will be a street car with occasional track days.

Any suggestions would be appreciated.

Bill

I had met a fellow at a car show who had a 351 like mine with 8 port injection but his ignition was an MSD and it started like a charm. He gave me a contact with the person who built his system. He was contacted and the car was taken to his shop. After 2 days of his checking things he noticed that the crankshaft would turn 6-10º before the distributor(cam sensor) would move. We believe it is timing chain stretch from all the backfiring, and the attempts to turn the engine backwards when this happened. He was going down to Daytona for the races (July 4th) as he is a member of one of the Nationwide pit crews and doubles as their tuner.

To save money and time, the car was brought home and the engine pulled. Inspection revealed the following. Notice the deflection and arrows.

I believe this introduced the rotor phasing I mentioned above and is retarding the timing even more so there is no real power stroke as firing is occurring on or about TDC. It still doesn't explain the backfiring up through the injectors though. Does this sound reasonable???

I have made the decision the go the MSD route and will install a new timing chain and either the digital 6AL-2, or the programmable unit as it will give me a rotor that will keep the fire on one cylinder at a time.

It was also discovered the crank trigger is an old one that has been altered(rounded out holes) so it can't be set to use the normal mounting holes as described in their video. It also has gouges out of the back of it. It isn't a new unit, and will be replaced.

Should the cam be "degreed in" or installed straight up? If degreed, should it be advanced or retarded? The car will be a street car with occasional track days.

Any suggestions would be appreciated.

Bill