Dear all

i´m in the process of collecting parts for changing my induction system from Holley to a WEBER IDA 48 setup.

I already have purchased a very nice pair of NOS IDA´s from a VW guy in germany. Don´t know where they have been made, because the embossed field after "made in" is kept blank. Nevertheless they are very nice and all tolerances which i can measure are ok.

Additionaly i did purchase a pair of brandnew spanish IDA´s.

They did look very nice from the outside ( although the casting surface is slightly rougher than on my NOS pair). Also from the inside they looked ok on the first sight. They dont feature the brass fuel float anymore .

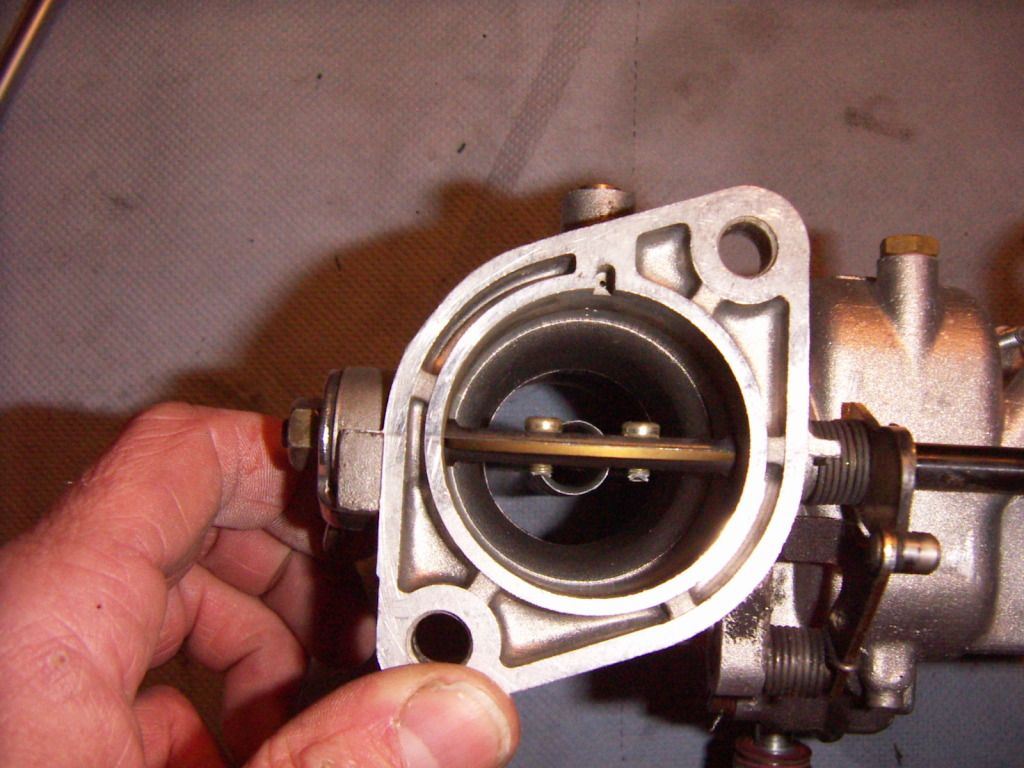

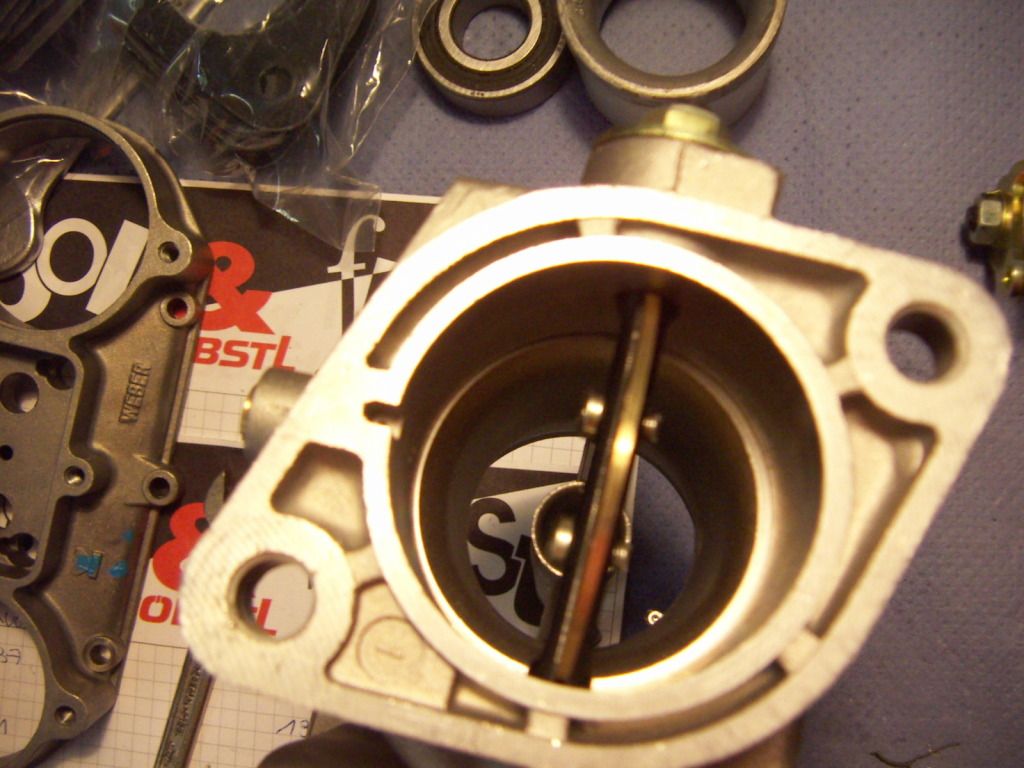

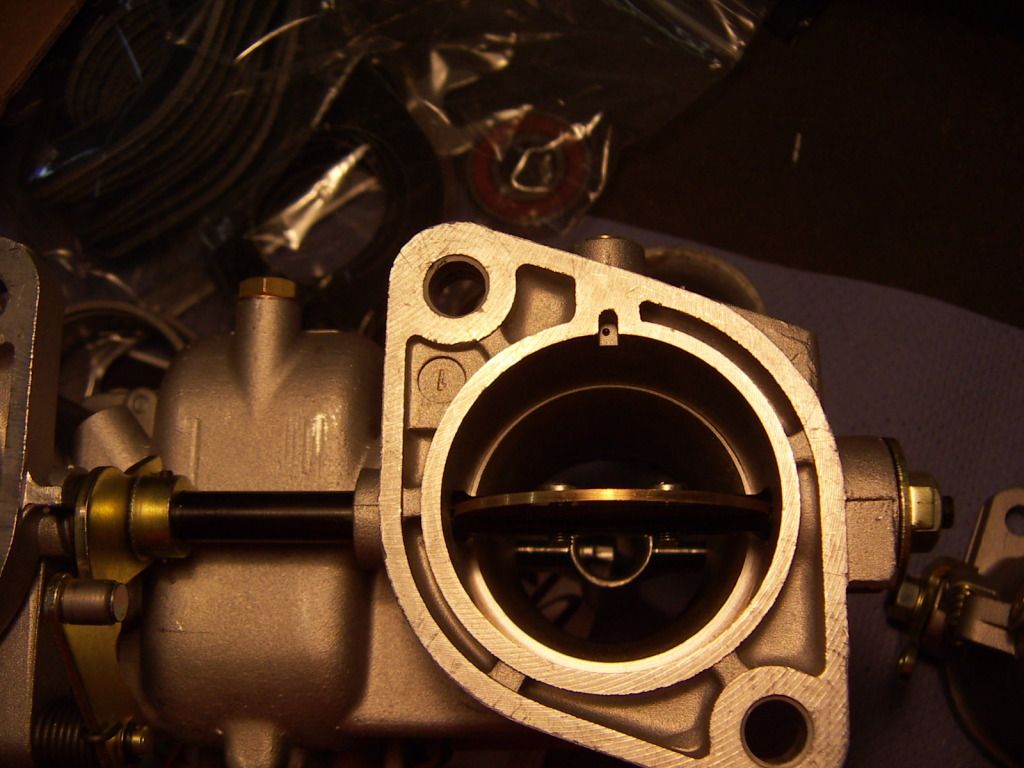

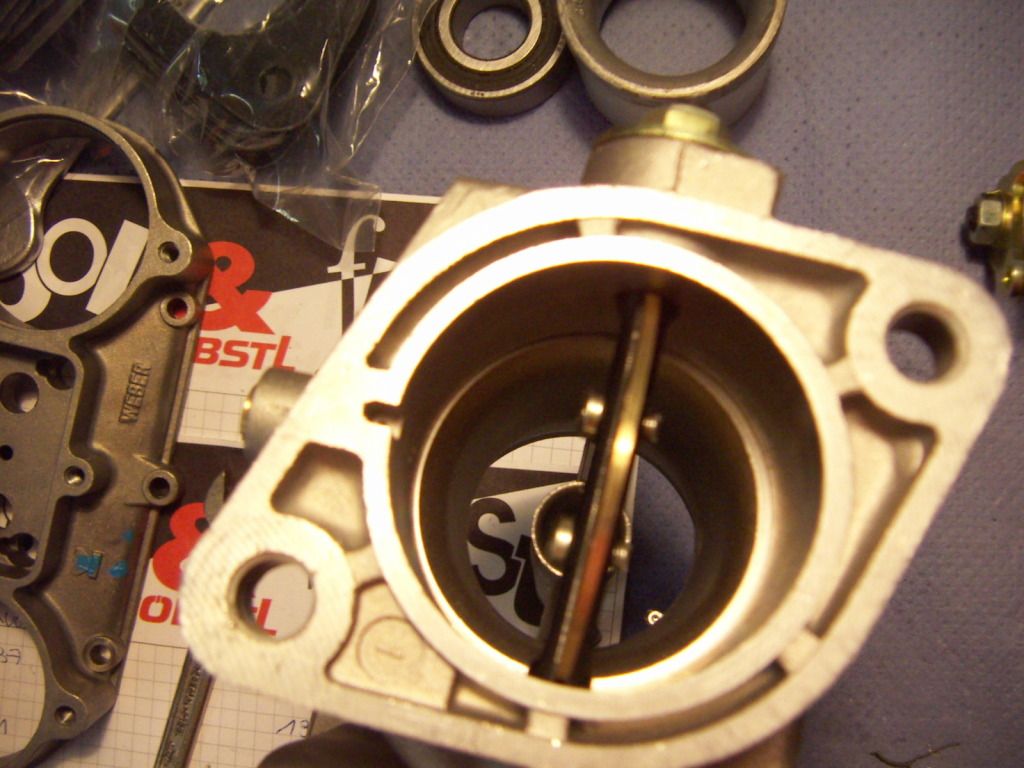

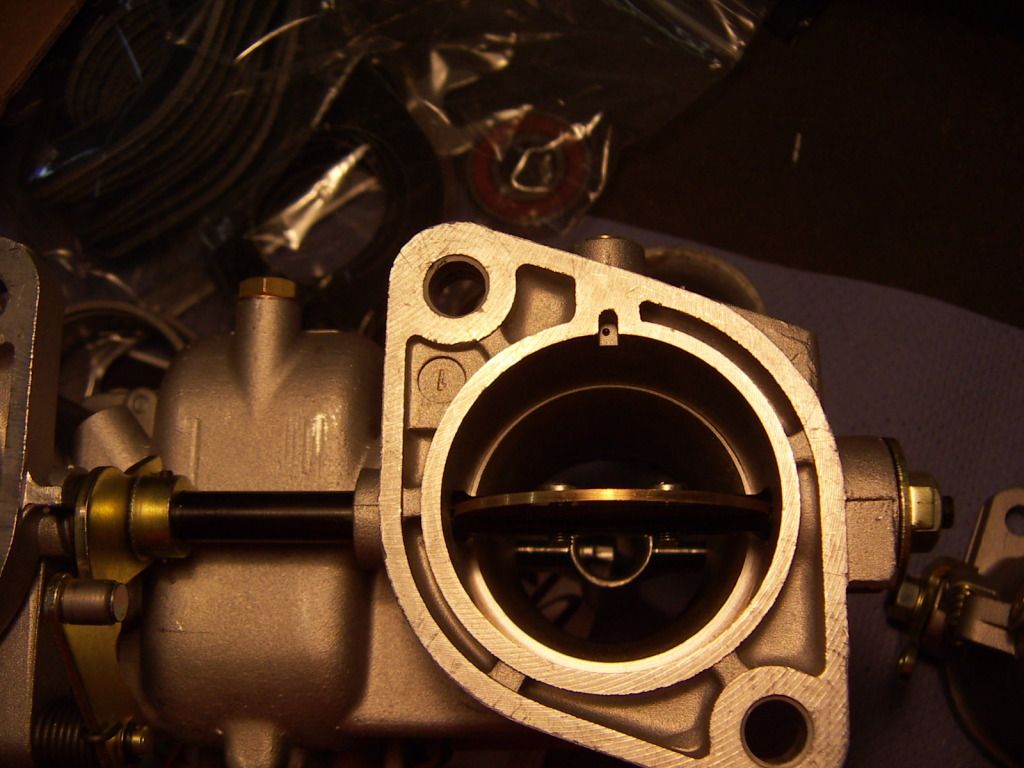

In closer inspection i found the following.

The bore of the venturi choke is app 1 - 1,5mm bored offset to the bore of the the throttle blade. This is consistently wron on every bore on each of the new carbs. The venturi bore of the NOS pair is exactly centered towards the throttle blade bore.

The dealer i purchased the carbs from checked his stock and also asked back at WEBER UK. According to his answer every of the carbs of this production run shows this issue. WEBER UK thanked me for the notation of this issue but also answered that they will continue to sell this stock givven the numbers of this already sold without complaints. They will inform the factory about this issue in order to correct it for the next batch ( good luck).

here are some pics.

As my engine needs a lot of air (331 with RPM up to 7800) i will have the need to optimise the flow through the carbs as good as possible to keep low rpm driveability ok and still moving enough air for the high RPMS without the need to go to the biggest venturi choke. To achieve this i have planned to remachine the Venturi choke by CNC to have no step on the transition from venturi to throttle blade bore and do flow optimisation on every other part as well which could be done without loosing signal strength on the main circuit. As this is not possible with this carbs i will send them back and look around for good ones.

THe dealer is taking the carbs back without any discussion and he has been very helpful and quick in getting answers.

So if you are in the processe of purchasing IDA´s look exactly what you get.

If anyone of you has a nice ( even used ) spare pair of 48 IDA´s which he would be willing to sell, please inform me.

Thanks

TOM

i´m in the process of collecting parts for changing my induction system from Holley to a WEBER IDA 48 setup.

I already have purchased a very nice pair of NOS IDA´s from a VW guy in germany. Don´t know where they have been made, because the embossed field after "made in" is kept blank. Nevertheless they are very nice and all tolerances which i can measure are ok.

Additionaly i did purchase a pair of brandnew spanish IDA´s.

They did look very nice from the outside ( although the casting surface is slightly rougher than on my NOS pair). Also from the inside they looked ok on the first sight. They dont feature the brass fuel float anymore .

In closer inspection i found the following.

The bore of the venturi choke is app 1 - 1,5mm bored offset to the bore of the the throttle blade. This is consistently wron on every bore on each of the new carbs. The venturi bore of the NOS pair is exactly centered towards the throttle blade bore.

The dealer i purchased the carbs from checked his stock and also asked back at WEBER UK. According to his answer every of the carbs of this production run shows this issue. WEBER UK thanked me for the notation of this issue but also answered that they will continue to sell this stock givven the numbers of this already sold without complaints. They will inform the factory about this issue in order to correct it for the next batch ( good luck).

here are some pics.

As my engine needs a lot of air (331 with RPM up to 7800) i will have the need to optimise the flow through the carbs as good as possible to keep low rpm driveability ok and still moving enough air for the high RPMS without the need to go to the biggest venturi choke. To achieve this i have planned to remachine the Venturi choke by CNC to have no step on the transition from venturi to throttle blade bore and do flow optimisation on every other part as well which could be done without loosing signal strength on the main circuit. As this is not possible with this carbs i will send them back and look around for good ones.

THe dealer is taking the carbs back without any discussion and he has been very helpful and quick in getting answers.

So if you are in the processe of purchasing IDA´s look exactly what you get.

If anyone of you has a nice ( even used ) spare pair of 48 IDA´s which he would be willing to sell, please inform me.

Thanks

TOM