I have completed the first step of the fuel system. It is enough to get the car running and on the road. I have made all the test and all works well. Crank up will come on Tuesday. Here is the ideal setup and it will be completed in the future if the way it is lined up runs into a problem from cornering or braking. I had already started on my system before I obtained this setup. So mine will differ a bit.

This system is for both tanks, one set of pumps and one fuel sending unit.

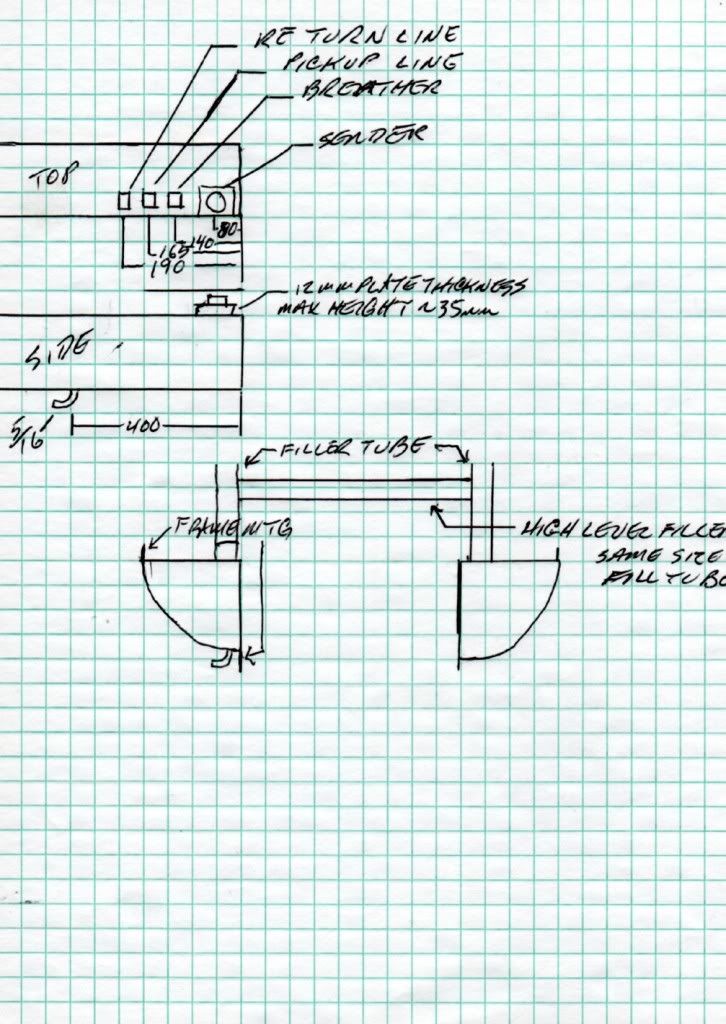

My system will involve the following. I am using one low pressure pump and one high pressure pump and one sending unit on the tank with the pumps. I went this way to conserve on cost and simplicity. Fewer thing to go wrong and lack of space for all the hoses.. Lord knows I don't need anything else to go wrong. So Here is the routing.The low pressure pump pick up is mounted on the rear of the passenger side tank. It could have been from the top as the drawing shows, but that area on the DRB has a frame rail above the tank leaving a one inch gap. There is a panel welded above the frame rail and that area holds the swirl pot, the 4 coils for that bank of plugs, and the rear clip fan. So it was getting a little crowded. An elbow connector on top of the access plate was too high. The fuel line would also have to be run through the frame rail and additional paneling to get to the pumps. The access plate was added to get the fuel pickup where it belonged(two right angle turns to get to the bottom of the tank and a sock filter is on the end) and to install the trap door. The trap door is to keep fuel in the rear of the tank so the pickup stays covered.

Just in front of the trap door about 3-4 inches is a set of baffles with a slit up the middle to prevent the sloshing of fuel to the front.

There are a series of these in the tank to slow down the wave movement of fuel in the tank. The fuel leaves the tank and goes through a Fram fuel filter to the low pressure pump. From there up to the swirl pot. Down to the high pressure pump. Up to the 10 micron filter and to the EFI. The fuel exits the fuel pressure regulator and returns to the swirl pot. From the swirl pot it overflows and returns to both tanks via a T arrangement. It enters the tanks about mid way up the tank, at the rear of the tanks. This allows the fuel to be returned on the passenger side in the trap door area. So fuel will always be there for the low pressure pump. Even on a long downhill run. In Tennessee the mountain runs are several miles long! In the drivers side tank, it dumps right over the crossover line. The two tanks are joined at the bottom of the tanks. There is a 5/16 connector between the tanks which levels the fuel in both tanks. This is mounted through the frame rails and secured to the bottom to the car. DRBs use the washboard floors so it hides and protects the fuel line.

You will notice in the drawing that there is a big crossover line in the front between the two filler lines. This would allow you to fill both tanks from one side of the car. That is a nice idea, but I don't have the room in the front clip area due to battery placement and I don't like the idea of that fuel line in the drivers compartment. I guess if it were a welded line I wouldn't worry so much. But it isn't and I will. Also, I modified the vent lines. I have vent lines from the rear and front of both tanks. The fronts and rears are linked and then go up to a vent next to the gas fillers. In line just before the vents are rollover valves that allow the tanks to breath with changing fuel levels., but will not allow fuel to go up the lines in braking, acceleration or lord help a shunt or rollover. The fuel fillers have screw down caps under the Lemans caps. The drawing doesn't show it but the ideal situation for the fuel pickup lines is to be T'd also, drawing from both tanks. for me that would entail hacking that tank to install another trap door so air would not be sucked up. So I am using only one pickup in the passenger side. Running my pumps with the motor off and no centrifugal or inertia forces acting, the fuel level in the passenger tank does not go dry with a five gallon load shared between the two tanks.

When I frist started this idea, I had the return line only to the drivers side and passive flow to the passenger side.What I observed was that the fuel level in the passenger side would drop to nearly completely empty. When shut off the level would rise.

So two things against the passive leveling(fuel return to one tank). First the obvious. The flow from the overflow was faster to the tank than the passive leveling. Second, I did that system before I put the rollover valves in line. The flow to the drivers side was so fast that fuel would fill the tank and shoot up the vent and out of the car.That was just sitting still with out any outside forces acting on the fuel. I guess if I had the rollover valves in line it would have stopped the fuel from squirting out of the vent and forced the fuel over to the other tank, but that still isn't a good situation. I believe that is why all modern cars that have vented tanks(locking gas caps) have rollover valves installed in their vent lines.

Bill