You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

James' GT-Forté scratch build GT40 MkI

- Thread starter harvs

- Start date

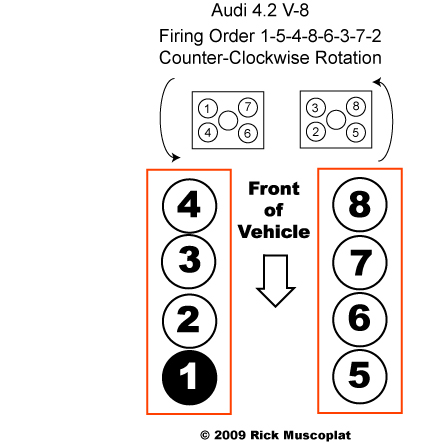

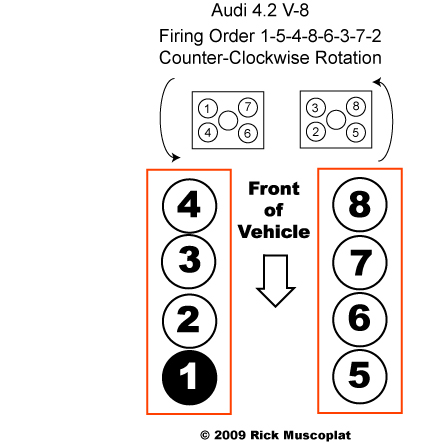

I've been thinking about how I'll do my exhaust - I want to go for the 180 degree arrangement. Does this look about right? I've avoided having the cylinders closest the front of the engine having to swap collectors and the cylinders which do swap sides go to the nearest side of the collector - so hopefully packaging should be slightly less difficult. (The collectors are viewed from the engine looking rearwards).

Does the ordering look ok?

Does the ordering look ok?

Attachments

A quick google throws up this

Which seems (once you reverse the rotation) to be identical.

So it's going to be different to the to the SBF and 1UZ-FE then (see below)?

I wonder how different it will sound?

X represents the flywheel end of the engine

1UZ-FE

1 2

3 4

5 6

7 8

X

Firing Order 1-8-4-3-6-5-7-2

Firing Order (Ford Cylinder numbering) 1-5-4-2-6-3-7-8

Audi ABZ

5 1

6 2

7 3

8 4

X

Firing Order 1-5-4-8-6-3-7-2

SBF

5 1

6 2

7 3

8 4

X

Firing Order 1-5-4-2-6-3-7-8

Which seems (once you reverse the rotation) to be identical.

So it's going to be different to the to the SBF and 1UZ-FE then (see below)?

I wonder how different it will sound?

X represents the flywheel end of the engine

1UZ-FE

1 2

3 4

5 6

7 8

X

Firing Order 1-8-4-3-6-5-7-2

Firing Order (Ford Cylinder numbering) 1-5-4-2-6-3-7-8

Audi ABZ

5 1

6 2

7 3

8 4

X

Firing Order 1-5-4-8-6-3-7-2

SBF

5 1

6 2

7 3

8 4

X

Firing Order 1-5-4-2-6-3-7-8

Thanks David. Think I prefer the thought of the rotations in the collectors going in opposite directions, rather than the same way as in that pic. Not that I think it would make that much difference...

Not sure about the different firing orders. As long as it's 180° I can't see how changing the firing order would make a difference?

Not sure about the different firing orders. As long as it's 180° I can't see how changing the firing order would make a difference?

Here we go, inner Audi Rzeppa type CV joints (the manual suggests some A4's also used tripod types), cheapest I've found them, they're for the 98-01 S4 which uses the 'DSY' 01E and has 260hp/295lb-ft (195kW/400Nm) so should be ok for decent amounts of power/torque. I've a slight unknown as I know Audi changed the flange PCD at some point but I think the 01E's are all the same.

AUDI S4 INNER CV JOINT (BRAND NEW) 98>01 - J & R Trading (UK) Ltd Store

No connection with them and no idea how good they are but a 2 year warranty on them would suggest they're not total rubbish.

As a follow up, these are not the right ones, at least they're wrong for my 01E anyway.

Hi David

What's wrong with them? Different size?

Have you looked at Car Parts Online, Spare Parts, Motor Spares from CarParts4Less.co.uk ?

There are kits listed there for £23 a side delivered...

What's wrong with them? Different size?

Have you looked at Car Parts Online, Spare Parts, Motor Spares from CarParts4Less.co.uk ?

There are kits listed there for £23 a side delivered...

- Int.teeth, diff.side, conn.to conn.shaft 33

- Internal Splines 33

- Joint Diameter (mm) 100

- Seal Diameter/ Body diameter (mm) 100

- Fitting Position Front Left & Right Inner

Too small, I'm not sure if it's that Audi used a different PCD on the earlier 01E boxes or they're just wrong full stop. Either way those ones won't work and I'm pretty sure the one you listed above won't either as I believe they are 130mm not 100mm (and to confuse matters further I believe there is a 108mm size Audi do too)

CarParts4Less don't list them for the Superb (which was my donor) but I'll have a look through the gearbox spreadsheet see if I can find one from an Audi.

CarParts4Less don't list them for the Superb (which was my donor) but I'll have a look through the gearbox spreadsheet see if I can find one from an Audi.

Interesting. The pcd of the bolt holes on my 01E flanges is about 115mm. Guess yours must be quite a bit more.

Ah, OK. We've got the same size then. Think tripodic cv joints are what were originally fitted. There's some info here - looks like they are hard to get though.

An alternative may be to use a different cv joint with an adaptor. Although this would shorten the shaft lengths and increase the angles a little.

I've received my custom flywheel today. Nice and shiney, seems a pity to hide it away in a gearbox!

An alternative may be to use a different cv joint with an adaptor. Although this would shorten the shaft lengths and increase the angles a little.

I've received my custom flywheel today. Nice and shiney, seems a pity to hide it away in a gearbox!

Attachments

Ooooh, shiny shiny!

Who did you get that from? (I need to get one made up at some point)

Ouch, maybe I should re-consider, make up an adapter and either re-use the granada ones or the S4 ones then. On the plus side making up an adapter means can equalise the driveshafts (the 01E flange spacing is asymmetric).

Who did you get that from? (I need to get one made up at some point)

Ouch, maybe I should re-consider, make up an adapter and either re-use the granada ones or the S4 ones then. On the plus side making up an adapter means can equalise the driveshafts (the 01E flange spacing is asymmetric).

Got it from these guys... dealt with Ben Crisp

TTV Racing Components

Unit 15 Notley Enterprise Park

Raydon Road

Colchester

CO7 6QD

Fax: 01473 312014

UK

We are movingon the 22-6-2013 please make a note of our new address.

TTV Industrial Ltd

t/a TTV Racing Components

Old London Road

Copdock

Ipswich

Suffolk

IP8 3JF

UK

TTV Racing component manufacturers - Flywheels, steel flywheels, aluminium flywheels, Pulleys, Valve guides, studs

TTV Racing Components

Unit 15 Notley Enterprise Park

Raydon Road

Colchester

CO7 6QD

Fax: 01473 312014

UK

We are movingon the 22-6-2013 please make a note of our new address.

TTV Industrial Ltd

t/a TTV Racing Components

Old London Road

Copdock

Ipswich

Suffolk

IP8 3JF

UK

TTV Racing component manufacturers - Flywheels, steel flywheels, aluminium flywheels, Pulleys, Valve guides, studs

I've been giving the engine some thought recently, in particular how I'm going to control it. I'm planning individual throttle bodies, so I'll definitely need to go with a standalone ECU. At the minute I'm leaning towards Megasquirt and probably MS3 so I can run fully sequential fuel and spark. I like the idea that I can build the Megasquirt myself. Looking over on MegaSquirt Engine Management Systems it sounds like an oscilloscope would be pretty handy for checking sensors / outputs etc. I've managed to get an analogue scope locally for a reasonable price. Also got an electronics book so I can brush up on Ohms law etc - it's been a little while since I did this at school!

Attachments

I've fabricated a metal folder / bending brake to bend the metal for the suspension U-brackets. I got to use the lathe for the first time (for turning down the internal hinge tube), which was good.

1 down, 19 U-brackets to go!

1 down, 19 U-brackets to go!

Attachments

I've fabricated a metal folder / bending brake to bend the metal for the suspension U-brackets. I got to use the lathe for the first time (for turning down the internal hinge tube), which was good.

1 down, 19 U-brackets to go!

Making a bending brake was the very first thing I did for my project. Has really come in handy for the aluminum body panels. You will probably need a wider version of it for those though. I think Darren said it needed to be over 40". Could measure mine if you like but I think the widest part you need to bend is the rear bulkhead as I recall. Not easy to do on mine as I used 6061-T6 and a bit thicker than he called for.

Hi Darrin. Yep, I've made a folder which is 1m wide too, so that will get used quite a bit when it comes to the panels. The little one is much stronger / rigid for bending the U-brackets. It's surprising how strong 3mm plate is!

Similar threads

- Replies

- 3

- Views

- 580

- Replies

- 3

- Views

- 801

- Replies

- 8

- Views

- 779

- Replies

- 25

- Views

- 3K