You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

monocoque

- Thread starter mission.gt40

- Start date

so is the monocoque identical wether its made from ali or steel ?

No.

The MkIV and I believe the two aluminium MkV's are rivetted aluminium honeycomb vs the welded steel of the MkI/MkII/MkIII/Other MkV's.

Not entirely sure if they're bonded as well, certainly if anyone was doing a modern version with an aluminium honeycomb it would be bonded these days.

MK5's are not honeycomb but just made from sheet aluminium.

The MK4 was Honeycomb.

Honeycomb material is much, much stronger.

It would make no sense to use flat sheet these days.

The rivets are there to hold the joints together while the adhesive sets.

Pics of a Tornado Aluminium Honeycomb GT40 Monocoque are attached.

The MK4 was Honeycomb.

Honeycomb material is much, much stronger.

It would make no sense to use flat sheet these days.

The rivets are there to hold the joints together while the adhesive sets.

Pics of a Tornado Aluminium Honeycomb GT40 Monocoque are attached.

Attachments

Ed McClements

Supporter

Here's a steel chassis in production for a Gelscoe car

You couldn't just copy this design, but use aluminium instead...the materials have completely different properties and need different chassis designs and construction methods. To see how an aluminium chassis is made, look at Marcus or Chris Goldsmith's Lola builds on this site.

You couldn't just copy this design, but use aluminium instead...the materials have completely different properties and need different chassis designs and construction methods. To see how an aluminium chassis is made, look at Marcus or Chris Goldsmith's Lola builds on this site.

MK5's are not honeycomb but just made from sheet aluminium.

Thanks Andy, that'll teach me to believe wikipedia where it stated those two were aluminium honeycomb!

The Mk V tub

looks like the photo is back to front.

page 119 of the legend lives on.

hello again

first off im loving this, been a member a week and theres already lovers tiffs lmao

I just know ford made an ali version of the gt40, they made aeroplanes ffs

heres an article that might get your brains cooking a bit and lotus have been doing

it for decades !!

A key component in chassis rigidity is the Flow Drilling Screws which are made by a company called EJOT in partnership with the company I work for ( Weber Screwdriving Systems ). The fasteners are applied to the two aluminum extrusions with bonding material sandwiched between, and using high rpm and high thrust ( both controlled by computer) and usually fixtured or as an end-effector on a robot. During installation the fastener is applied on the top surface of the materials being joined, it initially heats (locally) then allows the aluminum to "flow" through the mateials in question creating a small threaded hole and boss behind the joint which the FDS fills and is seated to a specific torque. This is 'air and water tight' and contracts & constricts around the fastener as it cools to give a hugely strong and rigid clamping of the materials being bonded. All of this happens in 1.5 seconds. This then allows the extr weusions and adhesive to be cured without movement or flex. Lightweight, rigid, and super strong. We also do the Lamborghini Gallardo, Opel / Vauxhall, and the Audi range of vehicles and several other automotive products. Only now are automotive manufacturers looking at this process for US cars.

glue and frigging torque screws

Get on this one DELO have made an epoxy that with 4 anquor points suspended a 17 tonne lorry

im deffo using that glue mmmmmm maybe M3 scotch weld

a full aluminium bonded gt40 has been made by ford, that's a fact, might be a prototype but they bloody did !! The holy grail and that's the one I want fellas.

im checking out the aluminium honeycomb this week and ill keep you informed !!

first off im loving this, been a member a week and theres already lovers tiffs lmao

I just know ford made an ali version of the gt40, they made aeroplanes ffs

heres an article that might get your brains cooking a bit and lotus have been doing

it for decades !!

A key component in chassis rigidity is the Flow Drilling Screws which are made by a company called EJOT in partnership with the company I work for ( Weber Screwdriving Systems ). The fasteners are applied to the two aluminum extrusions with bonding material sandwiched between, and using high rpm and high thrust ( both controlled by computer) and usually fixtured or as an end-effector on a robot. During installation the fastener is applied on the top surface of the materials being joined, it initially heats (locally) then allows the aluminum to "flow" through the mateials in question creating a small threaded hole and boss behind the joint which the FDS fills and is seated to a specific torque. This is 'air and water tight' and contracts & constricts around the fastener as it cools to give a hugely strong and rigid clamping of the materials being bonded. All of this happens in 1.5 seconds. This then allows the extr weusions and adhesive to be cured without movement or flex. Lightweight, rigid, and super strong. We also do the Lamborghini Gallardo, Opel / Vauxhall, and the Audi range of vehicles and several other automotive products. Only now are automotive manufacturers looking at this process for US cars.

glue and frigging torque screws

Get on this one DELO have made an epoxy that with 4 anquor points suspended a 17 tonne lorry

im deffo using that glue mmmmmm maybe M3 scotch weld

a full aluminium bonded gt40 has been made by ford, that's a fact, might be a prototype but they bloody did !! The holy grail and that's the one I want fellas.

im checking out the aluminium honeycomb this week and ill keep you informed !!

Attachments

JimmyMac

Lifetime Supporter

Not to forget Mick Ridley's aluminium build Eddy - excellent workmanshipHere's a steel chassis in production for a Gelscoe car

You couldn't just copy this design, but use aluminium instead...the materials have completely different properties and need different chassis designs and construction methods. To see how an aluminium chassis is made, look at Marcus or Chris Goldsmith's Lola builds on this site.

GT40 Aluminium Mononcoque Chassis

Here are some pics of an aluminium 16 swg rivited and bonded chassis Im building for my GT40 In these pics the chassis weighs 145 lb. The finished chassis will weigh less than 250 lb including all mounting points, and roll cage....

www.gt40s.com

great workmanship but not really in keeping with the legend hey ?Not to forget Mick Ridley's aluminium build Eddy - excellent workmanship

GT40 Aluminium Mononcoque Chassis

Here are some pics of an aluminium 16 swg rivited and bonded chassis Im building for my GT40 In these pics the chassis weighs 145 lb. The finished chassis will weigh less than 250 lb including all mounting points, and roll cage....www.gt40s.com

im not knocking him, each to their own n all that

You won't knock him, but his legacy. Mick can't respond anymore.great workmanship but not really in keeping with the legend hey ?

im not knocking him, each to their own n all that

Quote: "Car 110 had an aluminum tub and did not work out very well if I remember correctly. Alan Mann cars had aluminum body's , not sure if all Mann cars did."

GT/110 / X-1 McLaren Roadster AL tub

AMGT-1 MK-1 lightweight with AL panels, not all

AMGT-2 MK-1

lightweight with AL panels, not all

XGT-1 MK-II

lightweight with AL panels, not all

XGT-2 MK-II

lightweight with AL panels, not all

XGT-3 MK-II

lightweight with AL panels, not all

regards,

jim p

GT/110 / X-1 McLaren Roadster AL tub

AMGT-1 MK-1 lightweight with AL panels, not all

AMGT-2 MK-1

lightweight with AL panels, not all

XGT-1 MK-II

lightweight with AL panels, not all

XGT-2 MK-II

lightweight with AL panels, not all

XGT-3 MK-II

lightweight with AL panels, not all

regards,

jim p

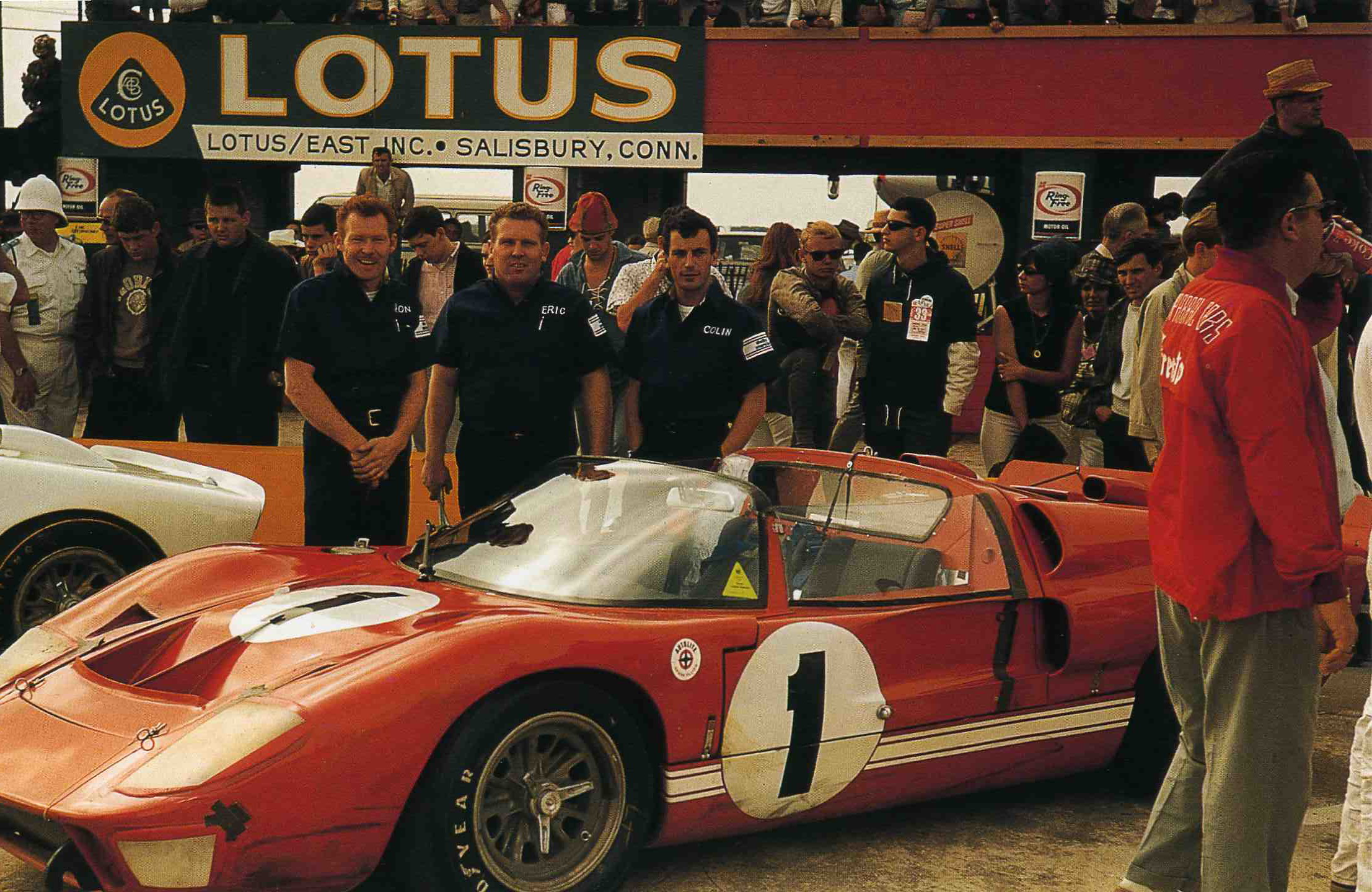

GT/110 / X-1 McLaren Roadster AL tub

Sebring Winner in 1966 at the hands of Mr Miles.

Similar threads

- Replies

- 3

- Views

- 349

- Replies

- 0

- Views

- 250