You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel widening ....

- Thread starter SJA

- Start date

There is a Swedish company that will widen wheels: Flgrikt Alu.svets o Smide - www.falgrikt.se

Stew,

I have mine out for widening to 12" right now. Supposed to be delivered back within the next two weeks.

It is company in germany with a great reputation about widening "porsche fuchs- rims" and other rims.

.....:::::Rindt-Felgen:::::.....

Will post pictures as soon i´m back from a trip to US ( hopefully the wheels are in my workshop when i arrive)

TOM

I have mine out for widening to 12" right now. Supposed to be delivered back within the next two weeks.

It is company in germany with a great reputation about widening "porsche fuchs- rims" and other rims.

.....:::::Rindt-Felgen:::::.....

Will post pictures as soon i´m back from a trip to US ( hopefully the wheels are in my workshop when i arrive)

TOM

GOT my Wheels back ( after the promised lead time of 6 -8 weeks) from "Rindt Felgen".

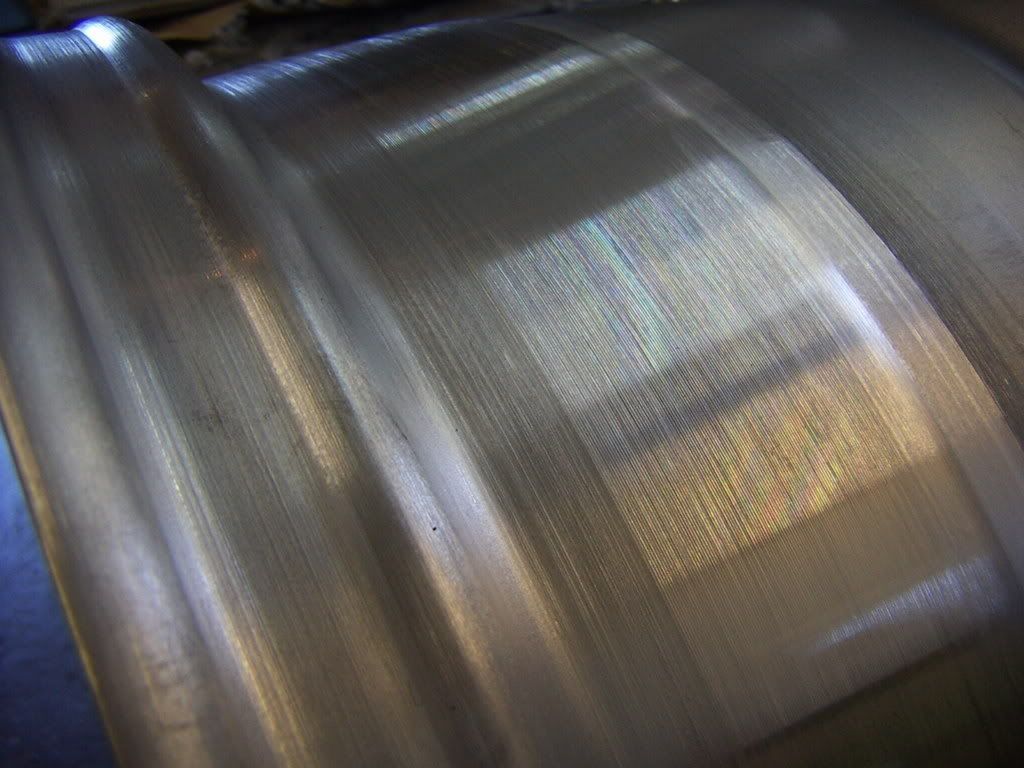

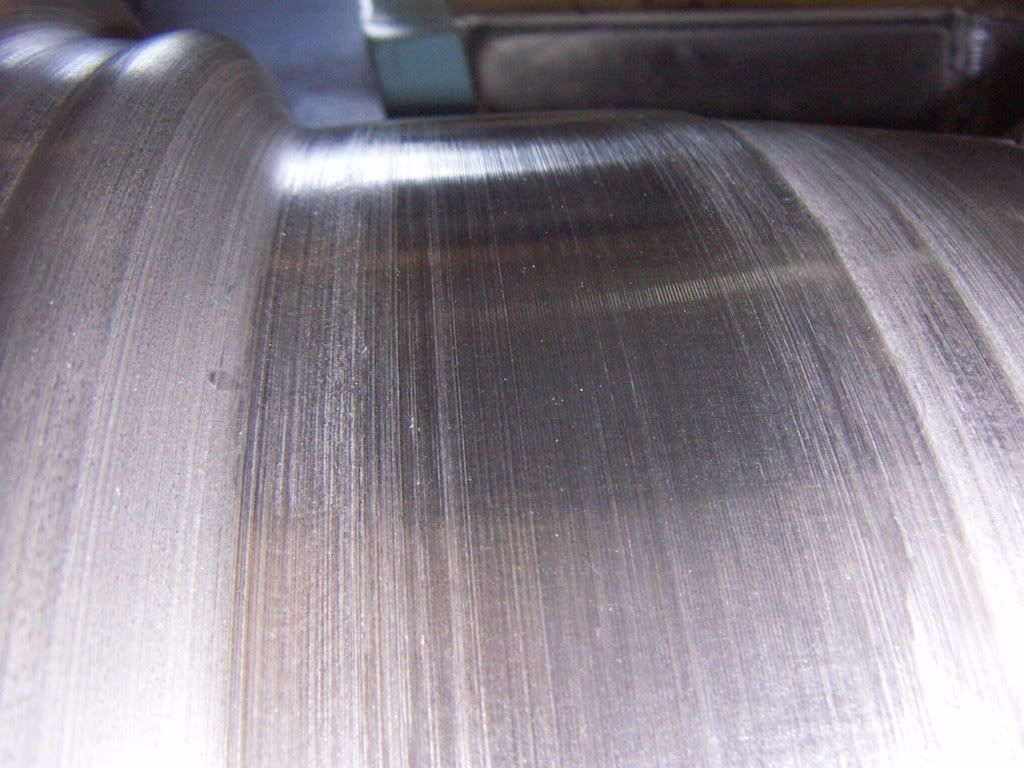

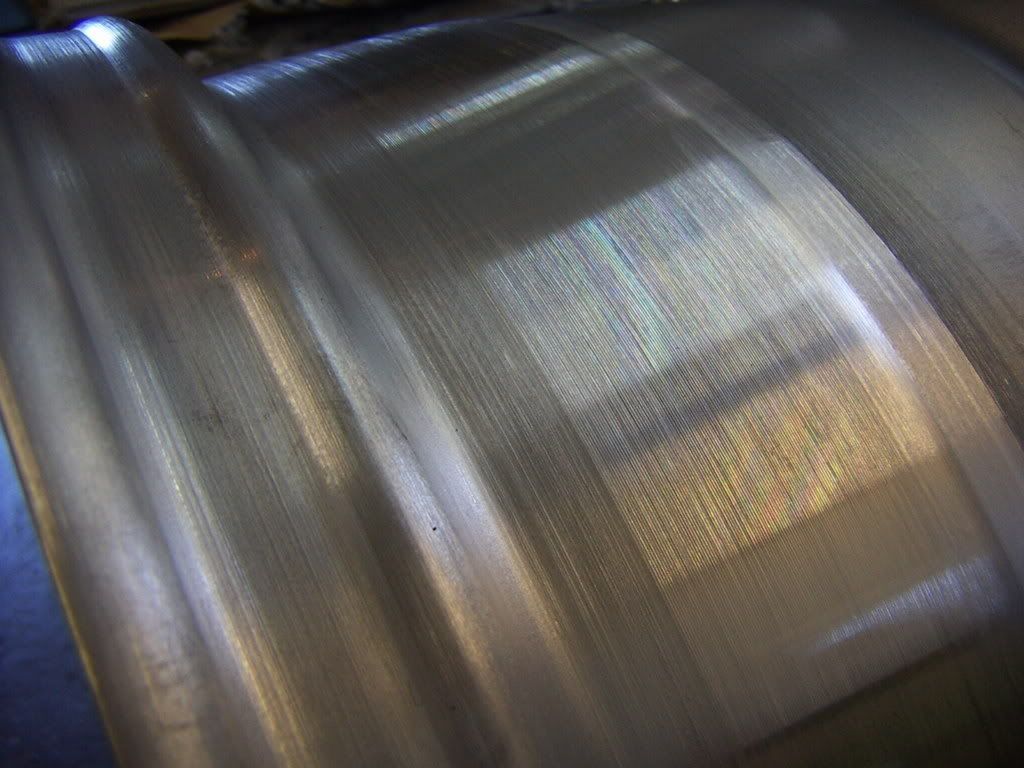

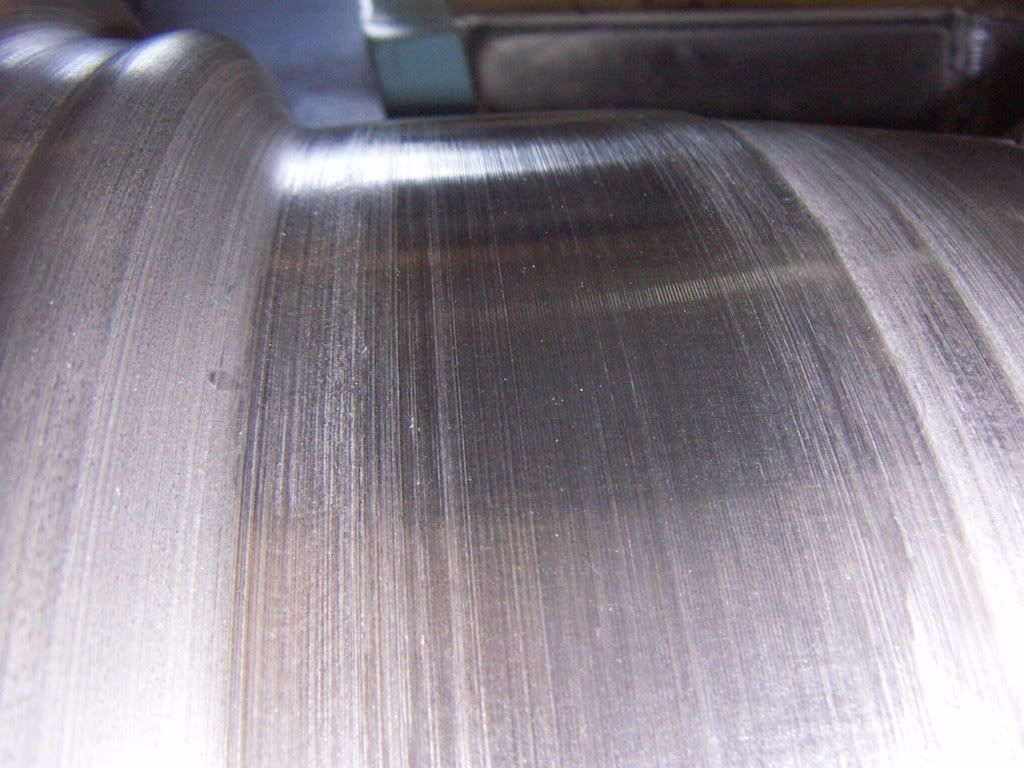

They look great. They cut the wheel and insert a closed ring. The ring is than welded in place from both sides and than turned down i a lay. As mentioned they do a lot of this wheels and also have a TUEV certificate for a smple wheel.

THe wheels look great. I will decide at the very end of the build how to finsih them. Right now i would opt for semi gloss black powdercoating.

The dimension is now 12x15" to fit the 345/35/15 PIRELLI.

Nice deep dish

TOM

They look great. They cut the wheel and insert a closed ring. The ring is than welded in place from both sides and than turned down i a lay. As mentioned they do a lot of this wheels and also have a TUEV certificate for a smple wheel.

THe wheels look great. I will decide at the very end of the build how to finsih them. Right now i would opt for semi gloss black powdercoating.

The dimension is now 12x15" to fit the 345/35/15 PIRELLI.

Nice deep dish

TOM

eglitom,

does the TUV certificate cover the process of widening the wheel ie the quality of the work or does it cover the design and or testing of the widened wheel, There is a big difference. I do work for TUV here in Australia, unlikely that TUV would certify the design but would certify the test procedure. Ask to see the certificate.

does the TUV certificate cover the process of widening the wheel ie the quality of the work or does it cover the design and or testing of the widened wheel, There is a big difference. I do work for TUV here in Australia, unlikely that TUV would certify the design but would certify the test procedure. Ask to see the certificate.

GOT my Wheels back ( after the promised lead time of 6 -8 weeks) from "Rindt Felgen".

TOM

I don't know much... but i know what i like... and those i like :thumbsup:

TUEV CERTIFICATE:

THey have both:

They are using a manufacturing procedure following the E.T.R.T.O . They are certified from TUW RW in foolwing this process standard.

For widened motorcycle wheels ( following the same procedure) they provide a TUEV certificate for the wheel(design) itself. For widened car wheels the economy of scale is not there, to test every single type of wheel to provide a according certificate.

For myself i know that they are good and provide a excellent quality work, never heard anything bad happening. Fine for me.

TOTAL COST:

Widening both wheels +2" : total cost including shipping in germany = 414 EUROS.

TOM

THey have both:

They are using a manufacturing procedure following the E.T.R.T.O . They are certified from TUW RW in foolwing this process standard.

For widened motorcycle wheels ( following the same procedure) they provide a TUEV certificate for the wheel(design) itself. For widened car wheels the economy of scale is not there, to test every single type of wheel to provide a according certificate.

For myself i know that they are good and provide a excellent quality work, never heard anything bad happening. Fine for me.

TOTAL COST:

Widening both wheels +2" : total cost including shipping in germany = 414 EUROS.

TOM

Tom,

Have you fitted a tire to these yet, I notice the 'well' of the 'original' width rim is smaller in dia at the point where you have some marker pen writing. As the wheel is now effectively larger in dia in this area due to the widening process it may make tire fitting a bit more difficult.

Have you fitted a tire to these yet, I notice the 'well' of the 'original' width rim is smaller in dia at the point where you have some marker pen writing. As the wheel is now effectively larger in dia in this area due to the widening process it may make tire fitting a bit more difficult.

So you are saying they dont have TUV certification for widening car wheels but they do have TUV certification for widening motorcycle wheels. I might suggest that the two applications are vastly different. The ETRTO (european tyre and rim technical organisation) specifies standard dimensions and engineering information for the design of wheels. They do not tell you how to make them.

I would at least want to see 100% radiography with zero porosity and method of heat treatment after welding.

The results of a failure would be catastrophic. Not trying to scare you or anyone else, just be sure of the quality of the work, not just that it looks good.

I would at least want to see 100% radiography with zero porosity and method of heat treatment after welding.

The results of a failure would be catastrophic. Not trying to scare you or anyone else, just be sure of the quality of the work, not just that it looks good.

Tom

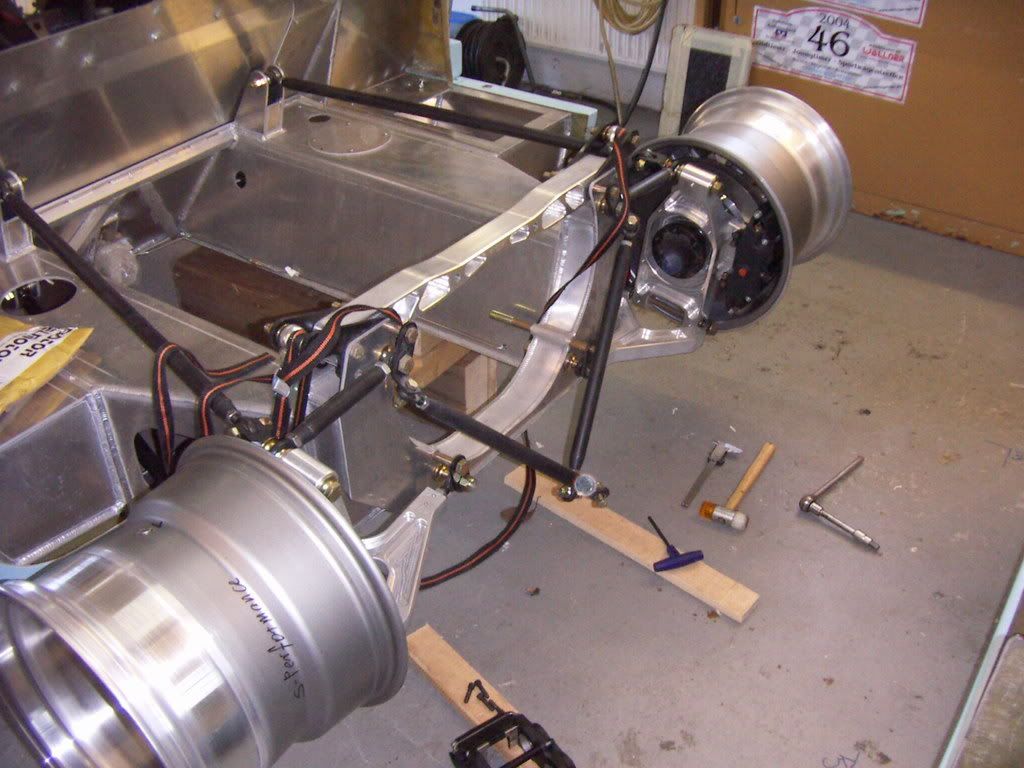

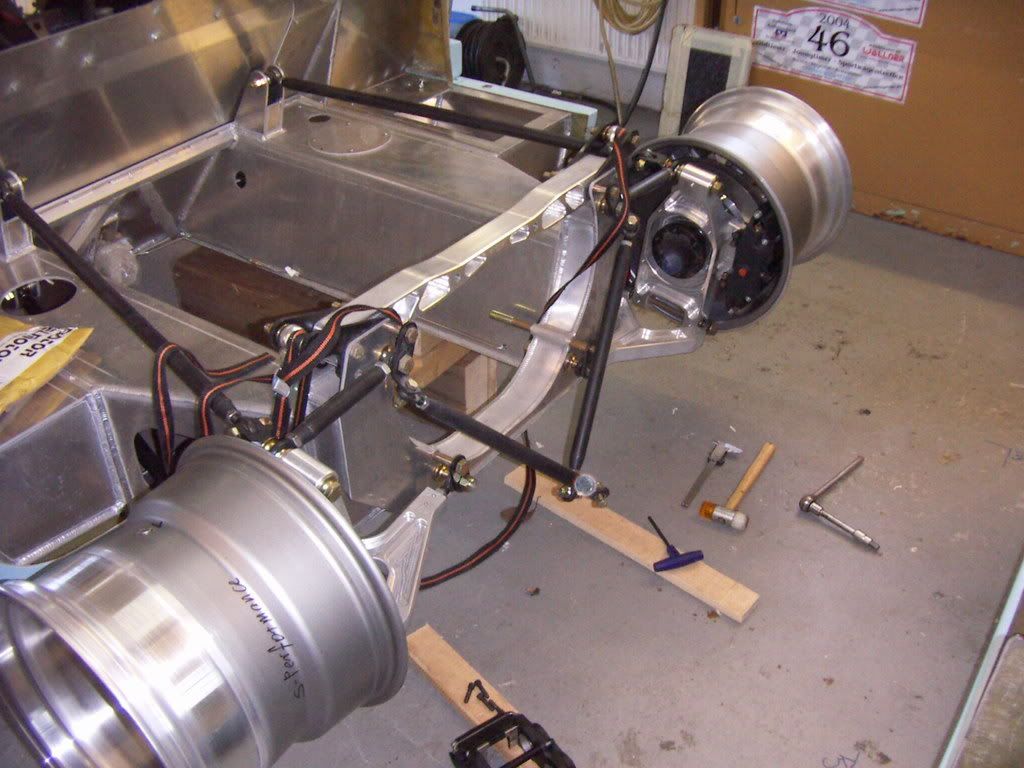

Looks like a nice fit to the chassis. Do you know the width across the top of the rear tread side to side? I am using a 15 X14 wheel in the rear with avons and I measure 76", (193mm) to the top of the tread, and approx 78", (198mm) to the outside of the tire. I was just curious how close to that you are.

Cheers

Phil

Looks like a nice fit to the chassis. Do you know the width across the top of the rear tread side to side? I am using a 15 X14 wheel in the rear with avons and I measure 76", (193mm) to the top of the tread, and approx 78", (198mm) to the outside of the tire. I was just curious how close to that you are.

Cheers

Phil

Attachments

Phil,

With the +2" wide track (each side) suspension mounted i have the following dimensions:

outside to outside: 73,5 " (1867 mm)

trhread to thread outside: 72,5" (1842 mm)

I wonder what the size of the wide orignals was ?

TOM

I think I recall the originals being 14" wide..

I think I recall the originals being 14" wide..

Randy, for the wheels you are correct ( some of them even had 15x15")

But the question i meant was the track width as measured by Phil and me ( outside to outside)

TOM

Tom

If I remember correctly the backspace on the original BRM wheels was 4 7/8", so with an original track of 56", that would leave 9 1/8" on each wheel. So 56" + 18 1/4 makes it approximately 74 1/4". I think that pin drive adapters might add a total of 3/4" to the overall width on some setups. Overall as long as suspension and body work clears I think most chassis will end up in this general area. I have no adapters on my rear uprights, but my bodywork measures 80" inside lip to lip, and I wanted to fill the wheel opening without rubbing.

I will take some accurate measurements and see exactly what my track is.

As you said let everyone decide for themselves, whatever works.

Cheers

Phil

If I remember correctly the backspace on the original BRM wheels was 4 7/8", so with an original track of 56", that would leave 9 1/8" on each wheel. So 56" + 18 1/4 makes it approximately 74 1/4". I think that pin drive adapters might add a total of 3/4" to the overall width on some setups. Overall as long as suspension and body work clears I think most chassis will end up in this general area. I have no adapters on my rear uprights, but my bodywork measures 80" inside lip to lip, and I wanted to fill the wheel opening without rubbing.

I will take some accurate measurements and see exactly what my track is.

As you said let everyone decide for themselves, whatever works.

Cheers

Phil

This confirms the original dimensions of the RCR 40, nice to hear.Tom

If I remember correctly the backspace on the original BRM wheels was 4 7/8", so with an original track of 56", that would leave 9 1/8" on each wheel. So 56" + 18 1/4 makes it approximately 74 1/4". I think that pin drive adapters might add a total of 3/4" to the overall width on some setups. Overall as long as suspension and body work clears I think most chassis will end up in this general area. I have no adapters on my rear uprights, but my bodywork measures 80" inside lip to lip, and I wanted to fill the wheel opening without rubbing.

I will take some accurate measurements and see exactly what my track is.

As you said let everyone decide for themselves, whatever works.

Cheers

Phil

I´m in the process of making my own flares now and realised of you go to close with the flare radius towards the top outside of the wheel it touchs the flare arc by moving in at app 10h and 14 h ( don´t know how to express it otherwise) so i need roughly a distance of 3/4 of an Inch from the vertical upright out line of the tire towards the top inner flare arc.

( will show pictures as soon i have the first mockup designs ready)

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 1

- Views

- 707