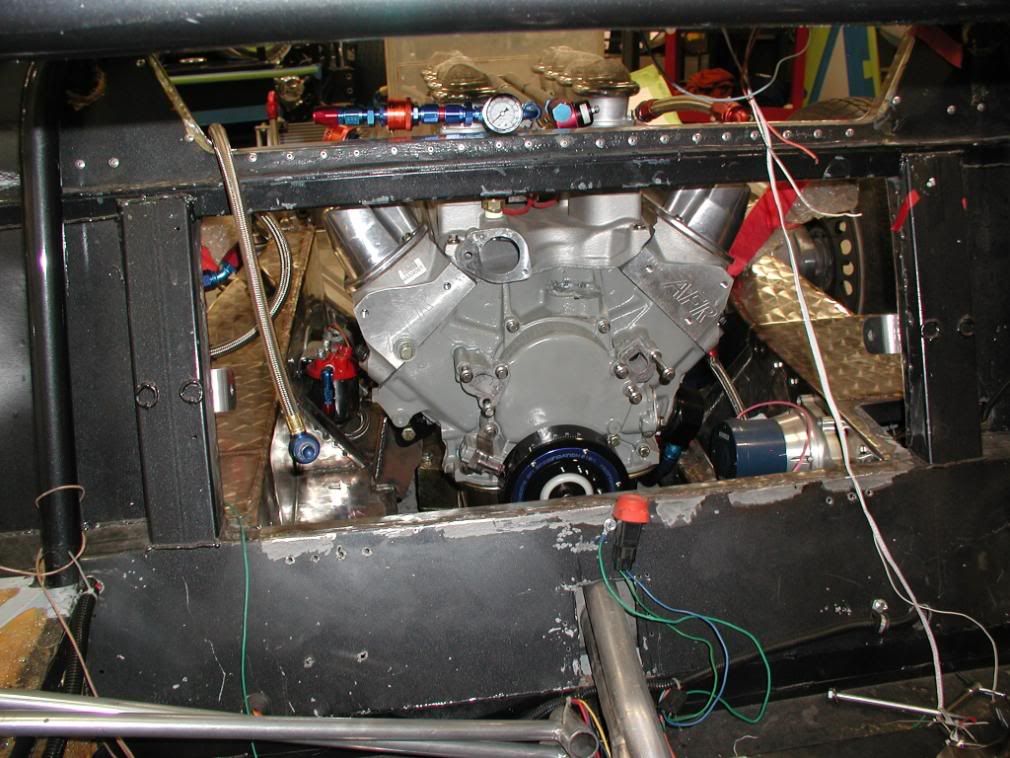

You surely should set your engine more forward, from the pics you seems to have enough room (and remember many GT40, including the originals, have their water pump pulley protruding in the cockpit through the firewall - you could use a shorter water pump if you don't fancy that idea).

This could maybe solve (or reduce) the drive shaft angle issue, and maybe also have the horseshoe clear the engine block.

For you oil filter no problem, you could use a remote filter, or a shorter one...

This could maybe solve (or reduce) the drive shaft angle issue, and maybe also have the horseshoe clear the engine block.

For you oil filter no problem, you could use a remote filter, or a shorter one...