Built me a new table for working on the Chassis today. Plan on going to get some tubing tomorrow & actually getting some progress done. Should have some pics to post in the near future (if all goes well LOL). Hope my engine/trans addapter kit gets here soon. Just got some stainless Heim ends for a great price.:thumbsup::thumbsup:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Lotus build

- Thread starter Mike S.

- Start date

Got word from Kennedy that it'll still be a few days till my adapter kit goes out. So today I made a makeshift adapter to get the trans/engine mated for length any way. Built a wood cradle so the engine sits level. Got them set in the frame & with a little measuring. Found out I didn't have as much of an oil pump clearance issue as I though (I'd only eyeballed it before.) By reversing the lower wish bone I'd made before. I should be able to bolt it to the trans cradle/bulkhead. Ordered 3lbs of nickel/bronze welding rod (fluxed) & that should be in by weeks end. So making some progress any way.

Never mind I think I figgured it out. Forgot had to upload to photobucket LOL

Anyway this is where I'm at with getting the Buick 215 in the Lotus frame. A little cutting off of what I'd done before & bolting & clamping. It looks like a little more Then it'll fit quite nicely. My Kennedy addapter should be here in the next few days.:thumbsup

Anyway this is where I'm at with getting the Buick 215 in the Lotus frame. A little cutting off of what I'd done before & bolting & clamping. It looks like a little more Then it'll fit quite nicely. My Kennedy addapter should be here in the next few days.:thumbsup

Last edited:

Mike, great build; being a Europa fan, I'm sure you're aware of Europa Engineering / Banks Service Station & the 62 Europa: Banks Type 62. Gorgeous lines on that car, and I think Richard even put a SBC in one for a US customer who "had" to have it.

Here's a twin turbo Alfa V6 that he built, which is more in keeping (IMO) with the car's character than a SBC (pic attached).

Your Buick motor ought to fit well too; it's a nice little compact and lightweight lump. Will you keep it carbureted or go EFI?

Here's a twin turbo Alfa V6 that he built, which is more in keeping (IMO) with the car's character than a SBC (pic attached).

Your Buick motor ought to fit well too; it's a nice little compact and lightweight lump. Will you keep it carbureted or go EFI?

Attachments

Hi John thanks yes I'm well aware of Banks LOL I've looked a lot at the pix of the tube chassis he's built. I've though about scrapping this frame for a tube one. One of my big concerns with the Europa. Is there is no side structure but the body fiberglass. I'm old school & not much into electric fuel injection. Probably just a 4bbl Holly. I'd love a 4X2 Weber set up but they are pretty expencive. It'll be a street only car so stay simple (cheap?). The tube you see sticking out one side will be for a roll bar though.

With the new V8 engine & wanting to use much bigger tires(was looking at some 295 50 15s today). I'm retinking using inboard brakes & go with outside ones. I'm a little leary of the torque on the rear axle from the inertia of a larger wider tire. The car itself won't be very heavy but I don't want to be wearing out brakes or snapping axles. Any advice from the collective wisdom here would be appreciated.

Been chopping steel & grinding & welding the last few days. Took some time to drive to Riverside this afternoon to pick up a new trans case. Went to get the wheels too but couldn't find the damned place. Guess they don't believe in signs so you can find them. I'll call again tomorrow & get better directions I gues. Hope to have some new progress pix soon. The Kennedy adapter kit came & is a thing of beauty. All billet aluminum & steel flywheel. Well worth the nearly $700 with shipping if it works a good as it looks.

With the new V8 engine & wanting to use much bigger tires(was looking at some 295 50 15s today). I'm retinking using inboard brakes & go with outside ones. I'm a little leary of the torque on the rear axle from the inertia of a larger wider tire. The car itself won't be very heavy but I don't want to be wearing out brakes or snapping axles. Any advice from the collective wisdom here would be appreciated.

Mike,

I wouldn't be too worried using 295/50/15's as far as inertia is concerned. Outside of Avons most 295/50/15's are pretty hard compounds and spin easily under initial acceleration. That's been my experience on my SPF GT40. Very interesting build you're doing. I also have a S1 Europa with 2L Zetec, but you're at a 47D level! I might be concerned with the Europa hubs and bearings. It looks like you have VW axles, but the hub bearings are standard? That arrangement may not hold up considering they're marginal on Europas with far less power than you're looking at.

Last edited:

I just got a new set of hub bearings. I think they'll be ok since I don't plan on racing it or doing anything too harsh with it. If the bearings don't hold up I'll just get some different ones & have the seats machined out to take them. I've decided to go back to at the wheel disk brakes. It'll solve several other problems of brackets & clearance. I have a set of Fiat X19 rear calipers & they are all alum. so nice & light. Yes I'm running the VW CV joints & stub axels welded into the stock drive axles. Will be close to what McLaren did but not splined. At aprox. 200+ horse I think it should all work ok.

Bought my new "Rhino" trans case & side plates & wheels & tires this week. Getting the frame & susp. tacked together & figuring things out. Re-did some of the things I'd done before & didn't really like (I'm my own worst enemy/critic). If it doesn't LOOK the way I think it should I'll re-do it again until I'm satisfied.

Been raining like crazy the last two days & can't get much done. The chassis is in the driveway. But went to Shore metals & got some steel I needed & did some welding in the garage on the radius rods & other brackets etc. So not a complete loss. I'll sand blast some parts & get them ready to paint. Hope to have it as a rolling chassis by the end of next week.

Yeah they beefed up the case with more ribs etc. The side plates are much heavier too. I'll probably be using molly stub axles too & molly CV joints. All that will still be cheaper than a Porsche trans & should be plenty strong for a 215. I've seen some monster power dune buggies that use bug trans & they seem to hold up ok. A lot of back pressure from the huge tires & soft sand etc.

The rain last week kind of slowed things up a little. But I was able to get a bunch of small stuff & susp. parts sand blasted, Primed & painted now. Got the engine mounts & brackets for the rear disc conversion made. Did some final welding on the chassis. I'll have to wait till I take the motor & trans back out. To flip it over to get to the rest of the welding though. Got the roll bar bent last week & going to do the recievers in the next couple of days. Soon it'll be sand blast time for the chassis. Paint & start assembling a rolling chassis :lol:

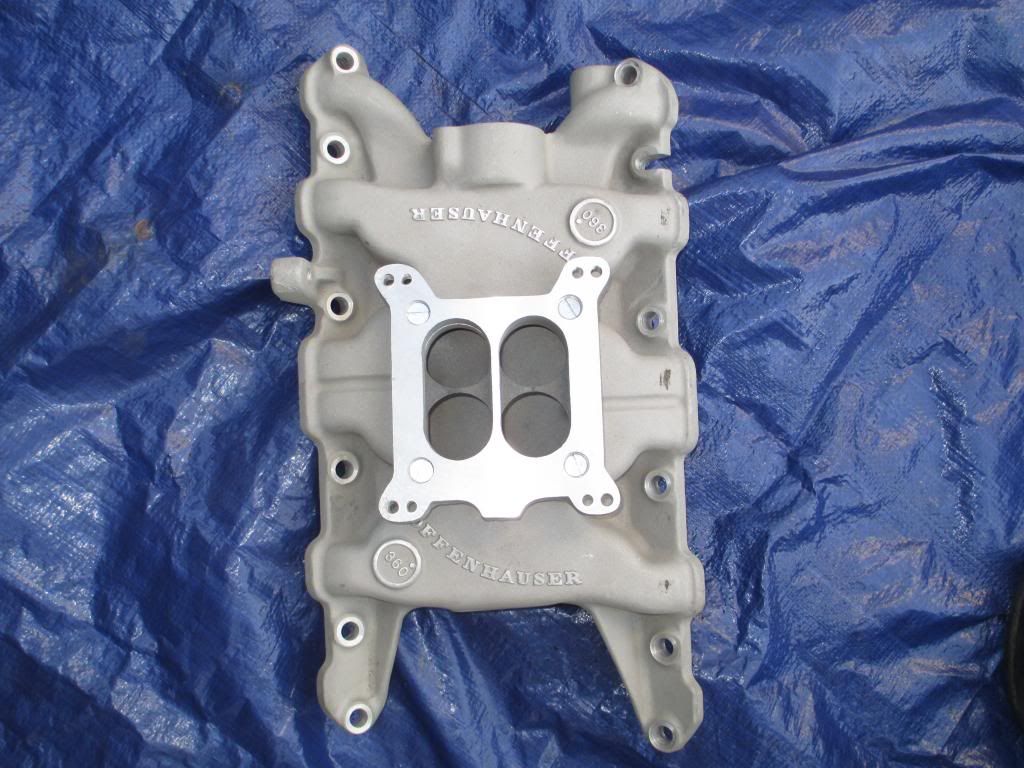

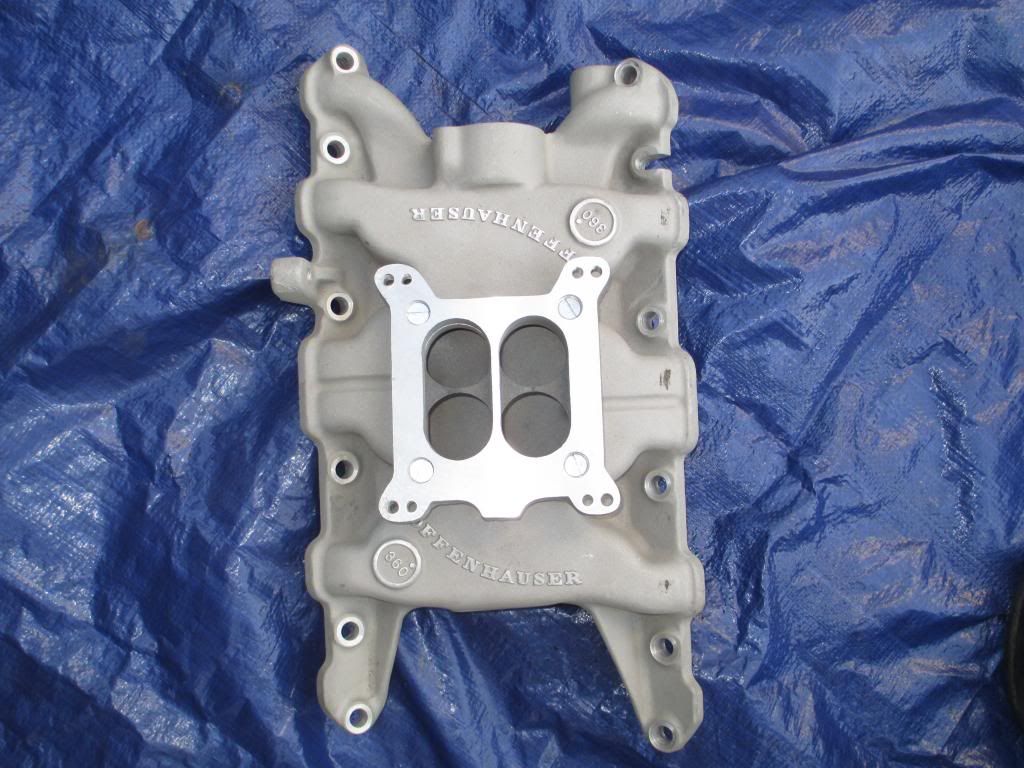

Got my Offy valve covers & intake. Look really nice I think & I like having the Offenhauser name showing. They've been closly associated with Indy & Can-Am for years. Have a little problem with clearance to the radius rods because of the width of tires & offset of the wheels. But I think I can get that cleared up without too much problems.

I like the concept. Europa engineering have a been racing a car that is along the same lines as your project. Not a v8 though

http://www.banks-europa.co.uk/gallery/gallery10/gtr_17.jpg

Model 62 GTR build

Bob

http://www.banks-europa.co.uk/gallery/gallery10/gtr_17.jpg

Model 62 GTR build

Bob

Last edited:

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 54

- Views

- 4K

- Replies

- 3

- Views

- 990