ACCUSUMP:

I´m going to install a 3 quart EPC controlled ACCUSUMP.

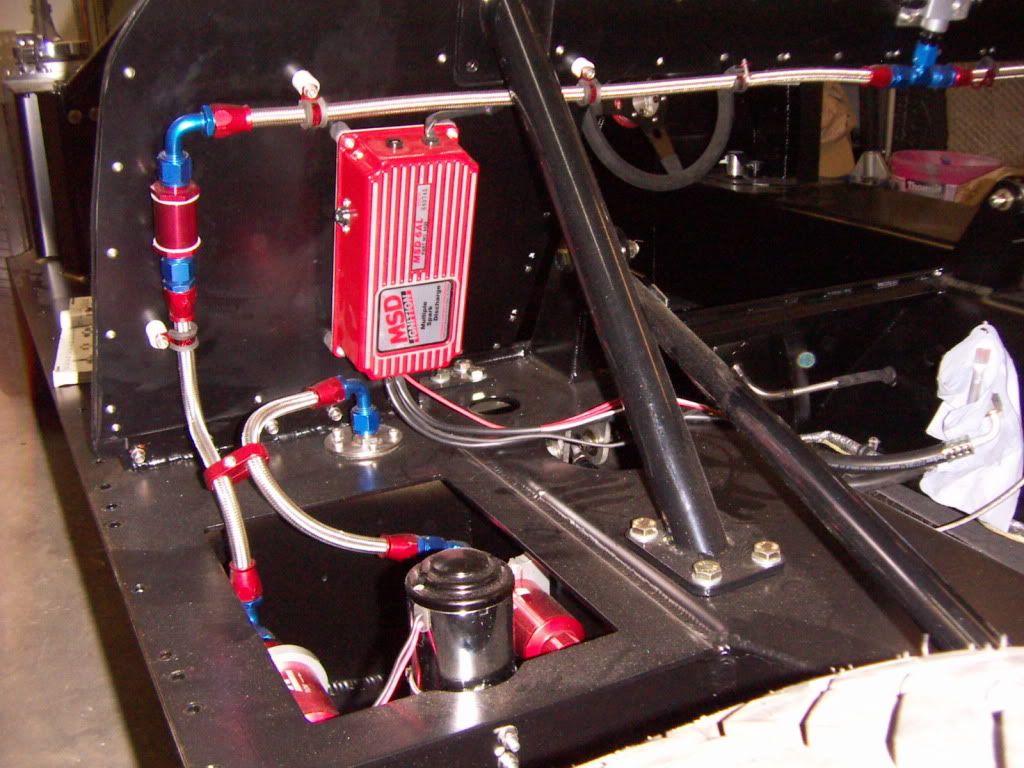

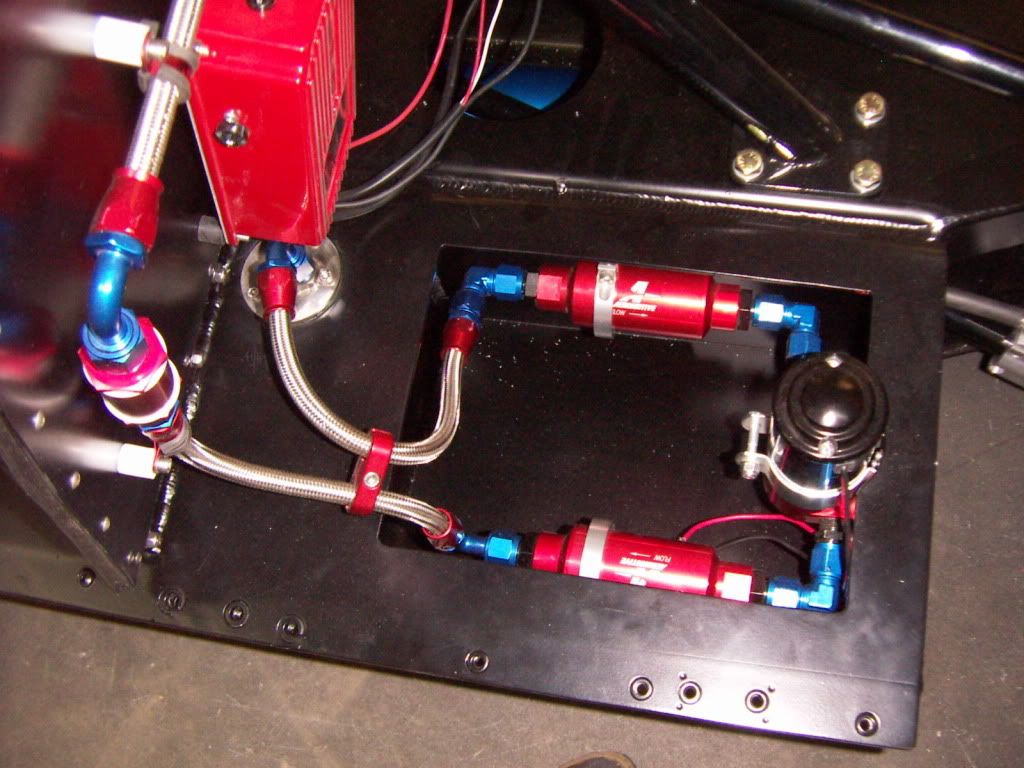

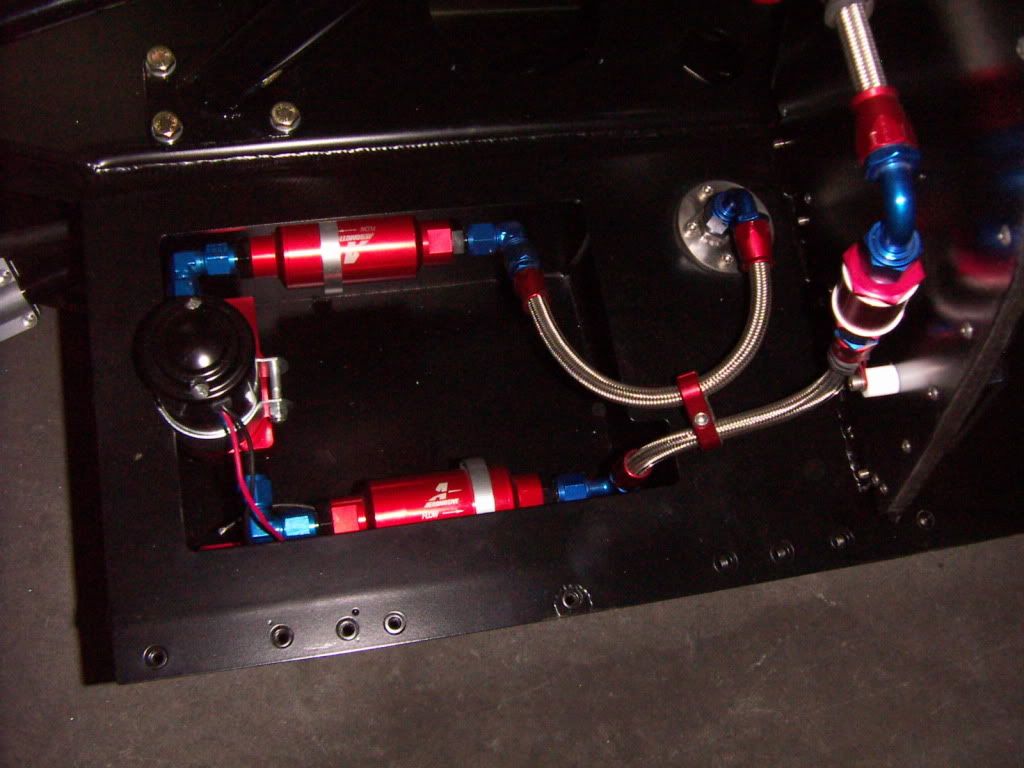

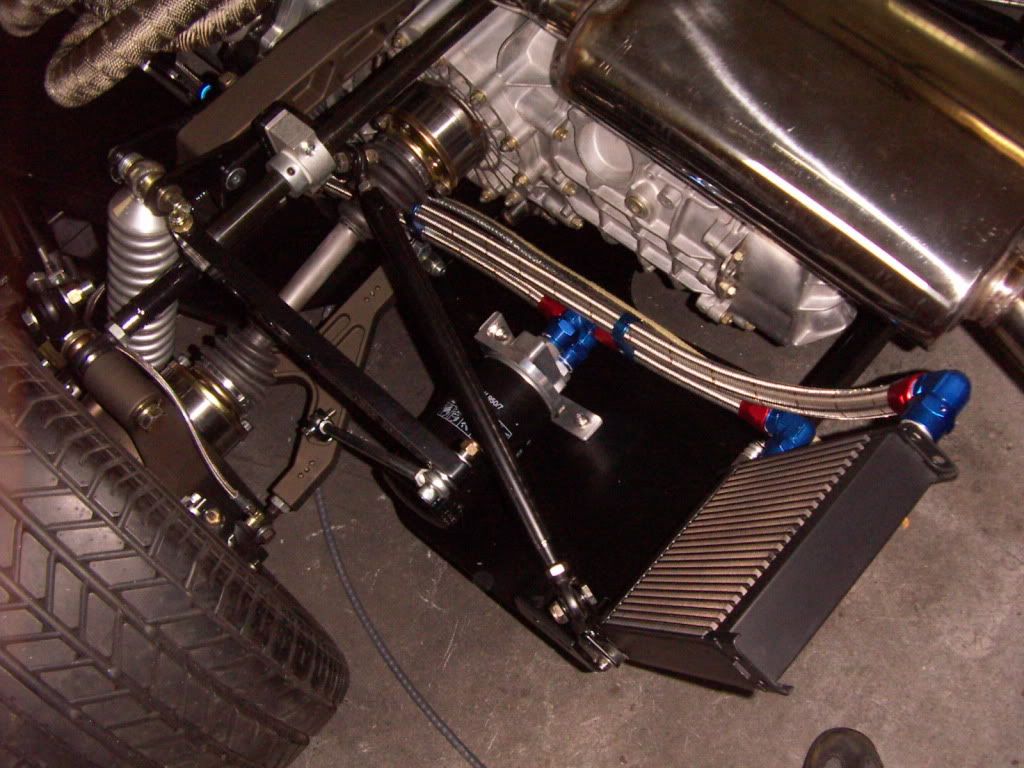

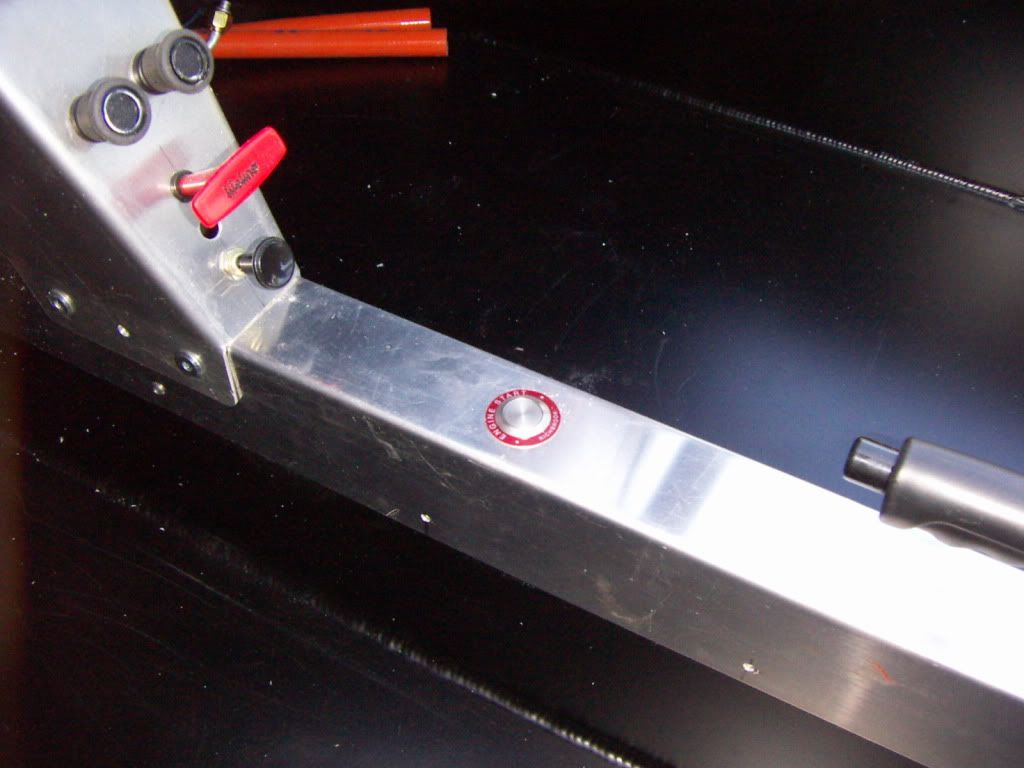

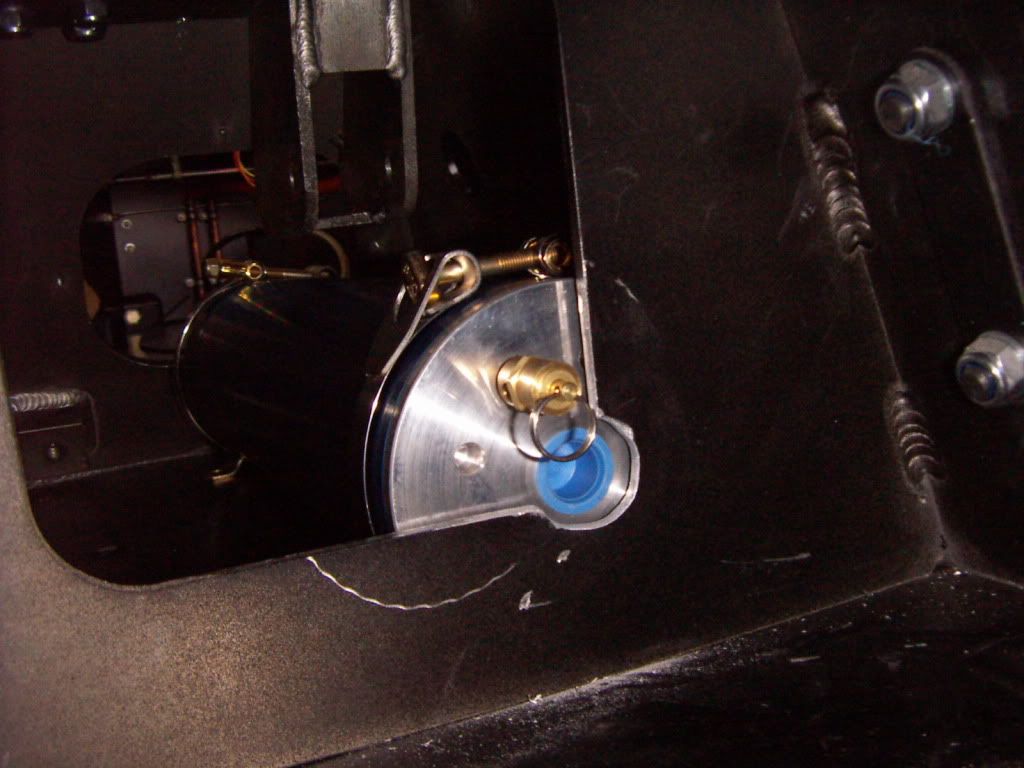

I placed the tank right behind the passenger side firewall in the inner sidepods. It is a very close fit in there but it fits. I think a perfect location. It is not visible there, the side pod can work as catch tank if something leaks, good also in terms of weight distribution. Short lines can be realised. In order to make it fit there, i had to adapt two small things.

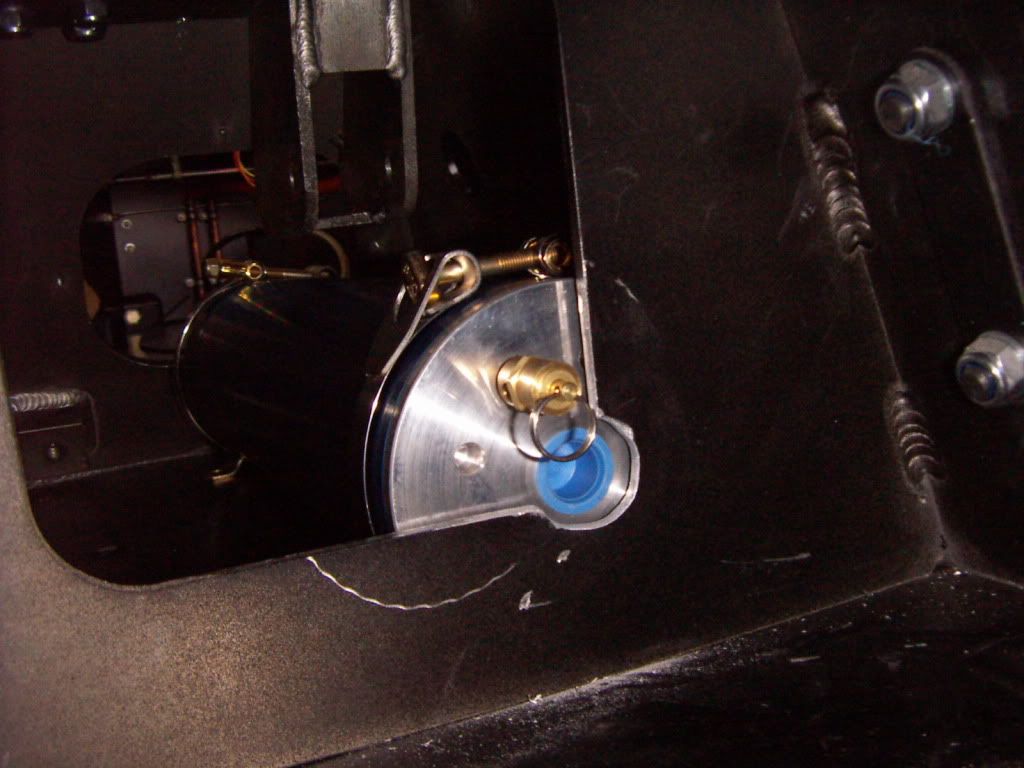

First the original pressure gauge adds to much to the total lenght and has to be relocated. I will place a nice smaller one in my middle tunnel, so that it is visible from the drivers position. This will give me a second oil pressure gauge ( just plus 7 PSI for the air) Hey RUSS what you think ? The other thing to adapt was a small notch out in the side pod for clearing the pressure line fitting.

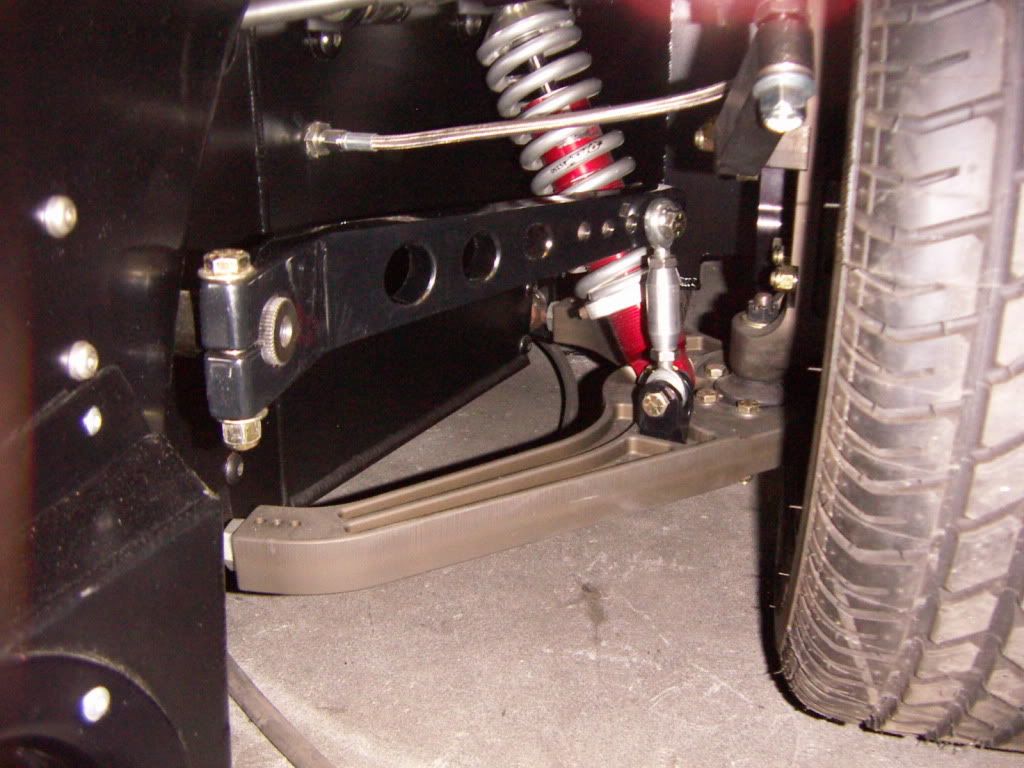

Radius rod in lowest position still clears

side pod notch out

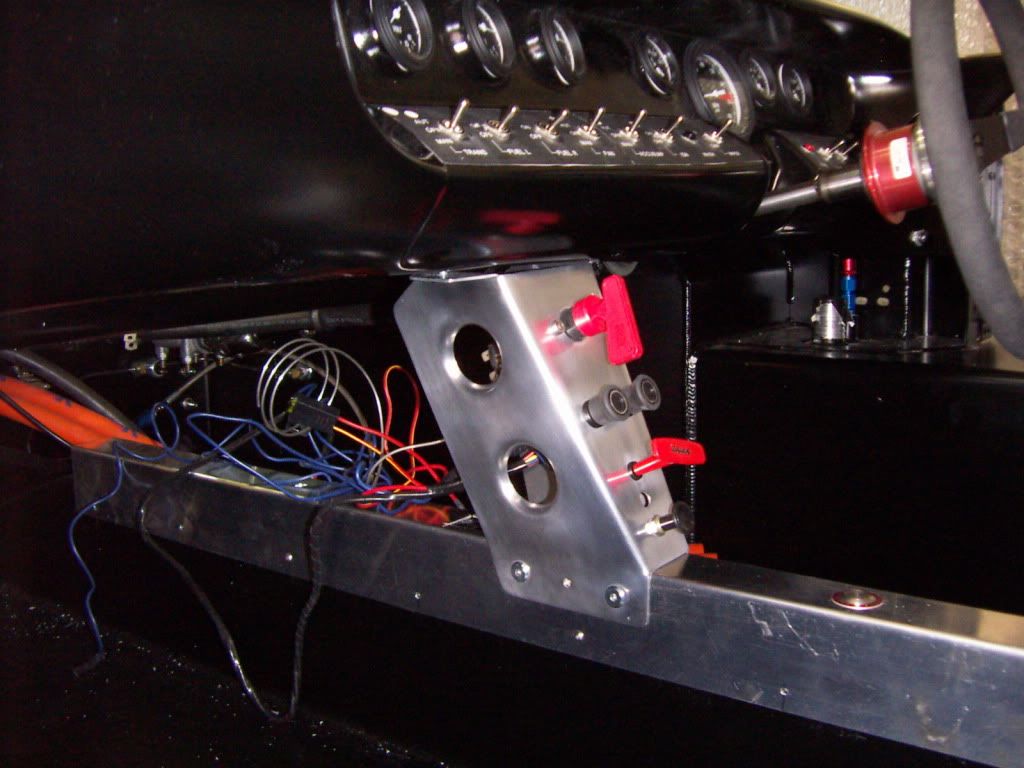

installed with the epc controller and valve

Front change to relocated pressure gauge . I´m using braided teflon hose for the first 15 " because of the heat, the rest is standard teflon hose. Love that nice little gauge.

Connection to the pressure line will be done with AN12 lines and an AN12 bulkead T. throught the sidewall of the engine sidepod.

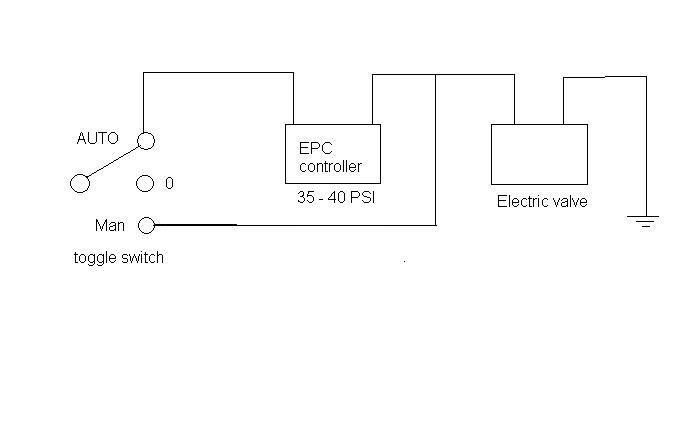

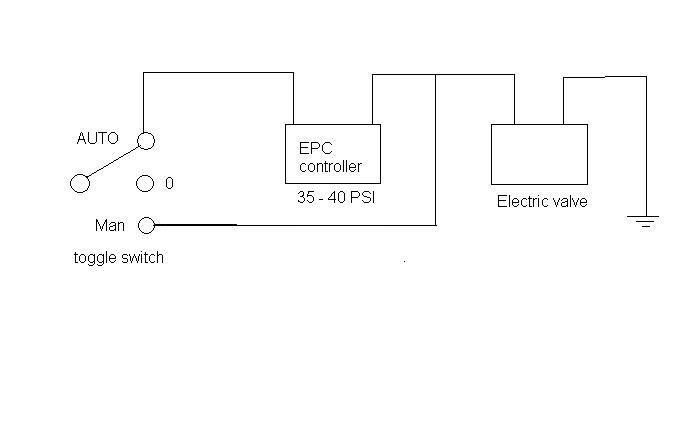

The electric installation will be done in a way that the valve is either pressure controlled activated or manually activated

TOM

AWH: 721 h

I´m going to install a 3 quart EPC controlled ACCUSUMP.

I placed the tank right behind the passenger side firewall in the inner sidepods. It is a very close fit in there but it fits. I think a perfect location. It is not visible there, the side pod can work as catch tank if something leaks, good also in terms of weight distribution. Short lines can be realised. In order to make it fit there, i had to adapt two small things.

First the original pressure gauge adds to much to the total lenght and has to be relocated. I will place a nice smaller one in my middle tunnel, so that it is visible from the drivers position. This will give me a second oil pressure gauge ( just plus 7 PSI for the air) Hey RUSS what you think ? The other thing to adapt was a small notch out in the side pod for clearing the pressure line fitting.

Radius rod in lowest position still clears

side pod notch out

installed with the epc controller and valve

Front change to relocated pressure gauge . I´m using braided teflon hose for the first 15 " because of the heat, the rest is standard teflon hose. Love that nice little gauge.

Connection to the pressure line will be done with AN12 lines and an AN12 bulkead T. throught the sidewall of the engine sidepod.

The electric installation will be done in a way that the valve is either pressure controlled activated or manually activated

TOM

AWH: 721 h

Last edited: