(going to assume everybody uses the same rcr pedal mount/wilwood setup here.....)

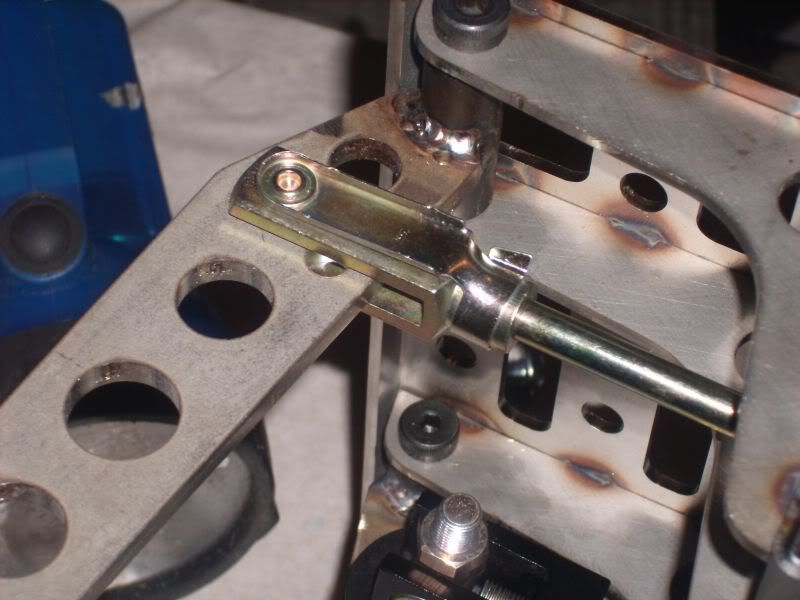

Installed the balancing bar into the brake pedal, cut the wilwood m/c brake studs, threaded them into the balancing bar. The face of the wilwood m/c sits flush against the mounting area of the pedal mount.

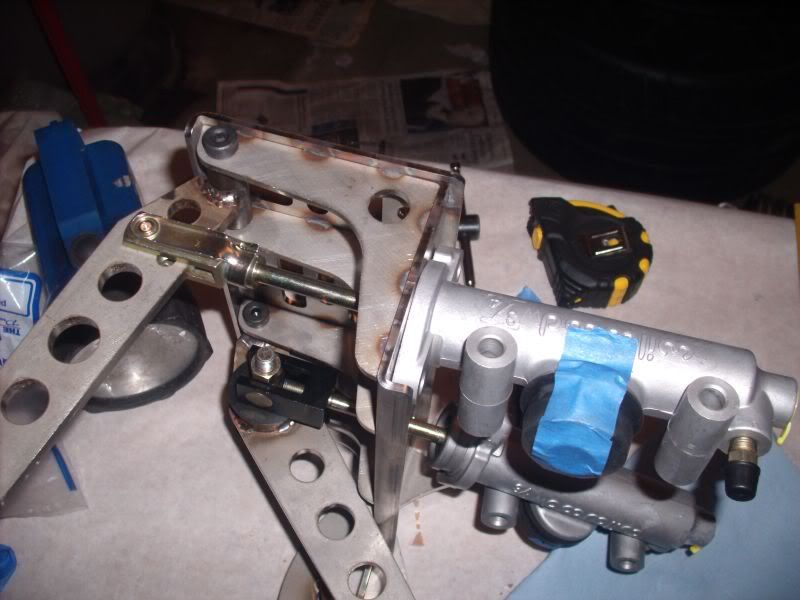

Repeat for the clutch side and, with the stud cut and bottomed out in the clevis (i.e., can't screw it in anymore because the beginning of the clevis is at the end of the threads on the stud) I have about 1/8'' or so of gap between the face of the wilwood m/c and the pedal mount.

If I give it gentle "force" I can get the cylinder face to mate perfectly onto the mounting area of the pedal box, but I'm worried that because it's not sitting flush by itself (i.e., I can't just screw it all the way in and have it sitting flush by itself...1/8'' or so gap until I push it into the mount) I've now got constant tension on the clutch system which will mean the clutch will be engaging to some degree all the time.........or maybe this isn't happening, I don't really know, so I figured i'd see if anybody else would describe their pedal mount install as such

Installed the balancing bar into the brake pedal, cut the wilwood m/c brake studs, threaded them into the balancing bar. The face of the wilwood m/c sits flush against the mounting area of the pedal mount.

Repeat for the clutch side and, with the stud cut and bottomed out in the clevis (i.e., can't screw it in anymore because the beginning of the clevis is at the end of the threads on the stud) I have about 1/8'' or so of gap between the face of the wilwood m/c and the pedal mount.

If I give it gentle "force" I can get the cylinder face to mate perfectly onto the mounting area of the pedal box, but I'm worried that because it's not sitting flush by itself (i.e., I can't just screw it all the way in and have it sitting flush by itself...1/8'' or so gap until I push it into the mount) I've now got constant tension on the clutch system which will mean the clutch will be engaging to some degree all the time.........or maybe this isn't happening, I don't really know, so I figured i'd see if anybody else would describe their pedal mount install as such