@JIMMYMAC - not that depression, I will try and cover it below, responses are coming in as I am writing this......

I have been pushing on. For those interested, this is the amount of drift, unknown or possibly just construction tolerance within the plans. It looks like I need to raise the engine up 0.27" in order to get part "GT40P-1-12084 'Bracket - Engine Mounting - Upper R.H.' " to sit inline or in plane with part "GT40P-1-2077 'Support - Engine Mounting Brackets - R.H.' ". This would put the engine mount bosses on the side of the block, very very close to 3" above the horizontal 0" datum line, which sounds very convenient, and possibly like a very believable number. It would line up with a 1-2-3 machinist block just nicely and allow something like this to have been used when setting up the engine on a build table. Note to self,

I will have to check the offset from engine mounting bosses to the sump face as i don't know if this is 3" or not. Another thing to confirm.

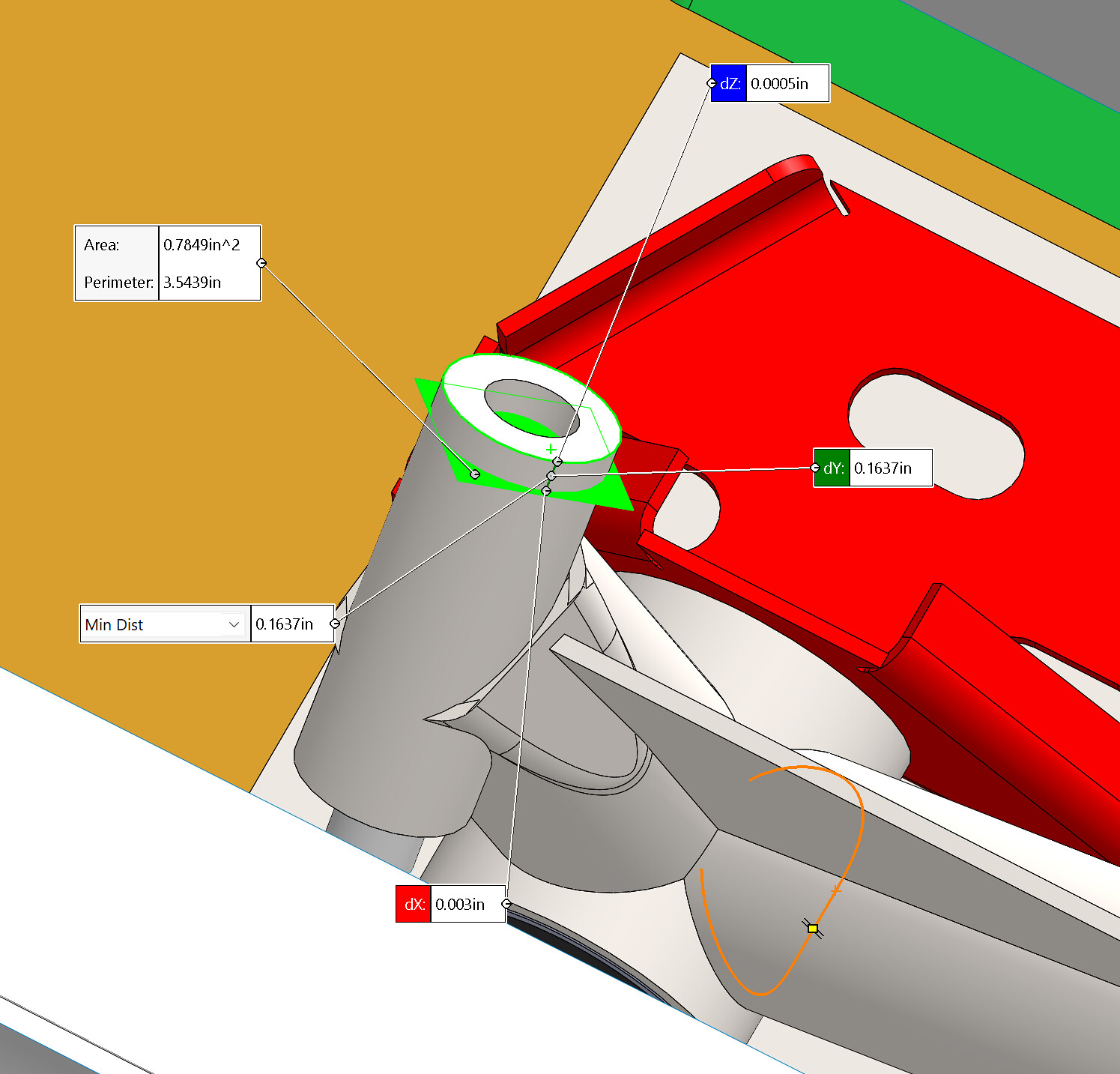

Ok, this below image will be a bit hard to see or understand without some extra explanation. So i will try and explain what each part is.

The Grey welded engine mount is where i had originally placed it to align the crank shaft axis with the transaxle input shaft axis, based on the ears on top of the gear box. This is based on having the engine mounted horizontal and parallel to the horizontal axis of the drawings. The engine mount is as per drawing GT40P-1-2562.

The purple engine mount is engine mount 2562 only that its raised up by 0.18". This is what I am trying to work out.

the mentalistic bush is 13-1657 as discussed above in this thread and is mounted concentrically to the grey engine mount. The central tube is 2" long.

The red upper bracket is GT40P-1-2084 and is located such that its 17/32" mounting hole is concentric and coincident with the top of the metalastic bush. This is where the 1/2" bolt would go through to secure the engine mount to the chassis.

Now the solid grey rectangle that I have sketched around with the bold black line is the cross section of GT40P-1-2077. part titled "Support Engine Mounting Brackets - R.H." and is the main chassis components that

@JIMMYMAC is showing above in post #10 of this thread.

This is drawn in position based on the location in its drawing.

@David Deschamps It is 16 SWG material (0.064" thick) projected upwards from the plane nominated in the drawing as that is how I read the dimension call outs.

Drawing 2077 is in the GT40 Uncovered book, so you would need to refer to that due to copyright.

On the drawing/projection of 2077 in the book, matching the projection below it shows that there is a depression in this plate, cross section DD. The depth of this depression would be 0.08" but it is only in the area around the metalastic bush, and not the upper bracket. So i either need to move the cross section of the plate down, or the engine up.

The last revision of drawing 2077 was Rev C on 12 Feb 65

On drawing 2107 which is the assembly of the whole engine mount area or sub assembly (revision C, dated 08 June 65). It lists parts 2076 and 2077 being deleted and parts 2754 and 2757 added to replace them. So shortly after drawing 2077 was updated for the last time, it was completely superseded by 2754

(2076 is the closing plate on the bottom of the lower engine mount of the chassis and 2057 supersedes it)

At this point, I am not sure which option to chose.

Do I

- Raise the engine at the front, so that it no longer sits level in the chassis and with its crank parallel to the horizontal plane of the drawings. Note that the engine mounts have the bolts that connect to the block canted backwards at a 40' angle and they are not parallel with the main chassis bolt when viewed from the side of the vehicle. Note I am not referring to the 45° on the front/rear view From the sketch below it looks like i need to raise it up that 0.27" at the chassis mount.

- Lower the cross section of part 2077 so that it lines up with where the engine wants to sit based on the position of the rear transaxle mounts. I don't have drawing 2754 to confirm what was done for the part when they superseded 2077.

It sure would be interesting to see some photos of early cars, pre 08/06/65, that show the original engine mount configuration. I wonder did the engine get raised? Does this date coincide with the dropping of the Colotti transaxle and the adoption of the 5DS-25? Or did the engine get raised by 1/4" for some reason

More research needed. Just goes to show why these things take so long to draw up. You have to research and reverse engineer the changes.

I might start sketching in a few of the other drawings i have, or scaling those and dropping them in as well. See if that changes my thinking.

I suppose its good to see that through out all this, the parts are within 1/4" in CAD when there is no tolerance. A lot of these parts were hand formed on the original cars and then drawn up afterwards.

Hopefully what I have written can be understood and is of interest to some.

Ryan