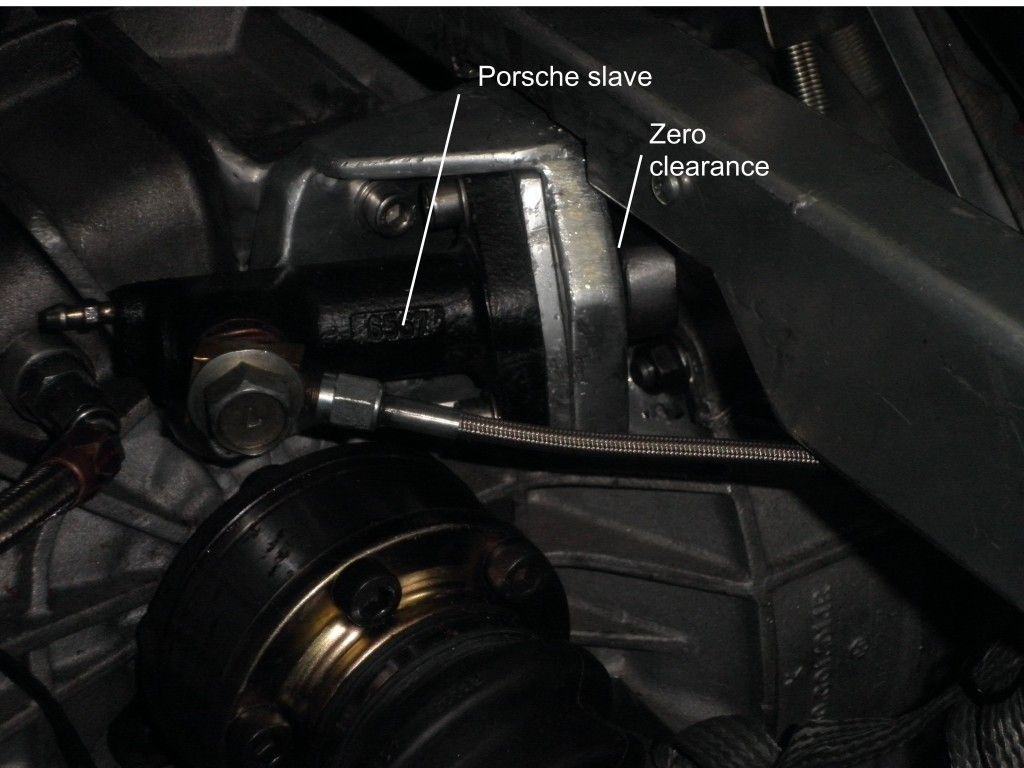

Given a size of master cylinder and slave, my pedal needs to go to the firewall to get the clutch to release completly. Very slight grind on down shift. The slave is a non exchange item as the way it is mounted. To get it to release sooner which way should I go for trying to get the action I want. Should I go to a larger master? Will this give me a softer pedal as well? Thanks in advance.

Bill

Bill