<TABLE id=ncode_imageresizer_warning_10 class=ncode_imageresizer_warning width=580> <TBODY> <TR> <TD class=td1 width=20> </TD> <TD class=td2 unselectable="on">This image has been resized. Click this bar to view the full image. The original image is sized 800x450 and weights 223KB.</TD></TR></TBODY></TABLE>

</TD> <TD class=td2 unselectable="on">This image has been resized. Click this bar to view the full image. The original image is sized 800x450 and weights 223KB.</TD></TR></TBODY></TABLE>

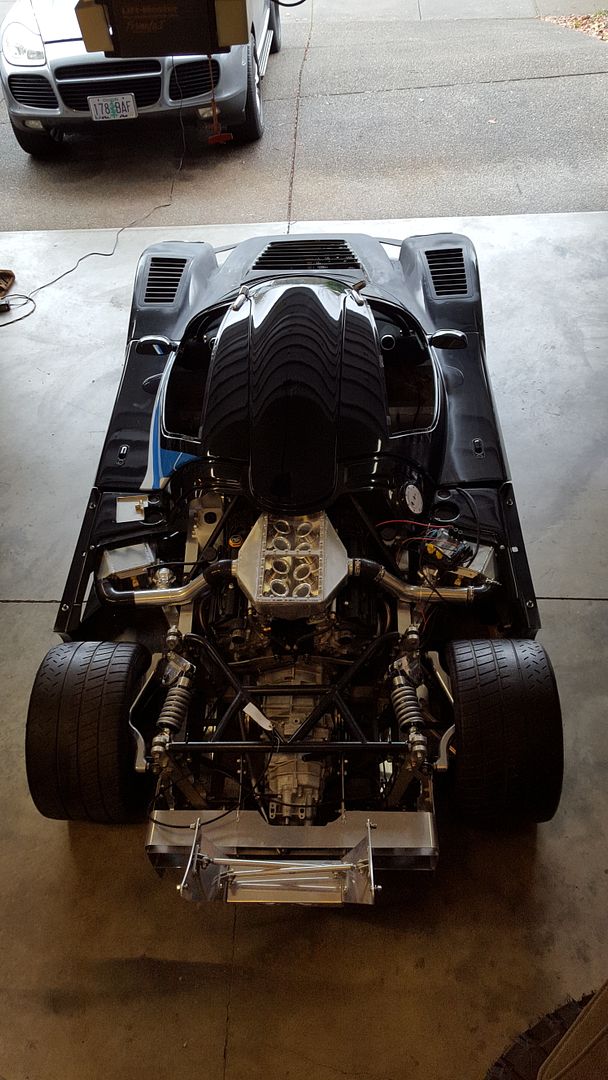

This shot shows like no other just how N-A-S-T-Y looking your car is becoming!

'U-N-B-E-L-I-E-V-A-B-L-E... :2thumbsup:

This shot shows like no other just how N-A-S-T-Y looking your car is becoming!

'U-N-B-E-L-I-E-V-A-B-L-E... :2thumbsup: