I am going to school to be a Machinist. I am also taking a laser class. We are required to cut out at lest three things. I got the dumb idea to do some thing SLC related. I planed on making a sign out if it. With SLC and super light coupe text on the top and bottom. Then maybe put some sort of lights behind it. I think it would look pretty cool.

I wanted to do some thing like this. http://www.cartype.com/pics/5917/full/panamera_profile-art.jpg

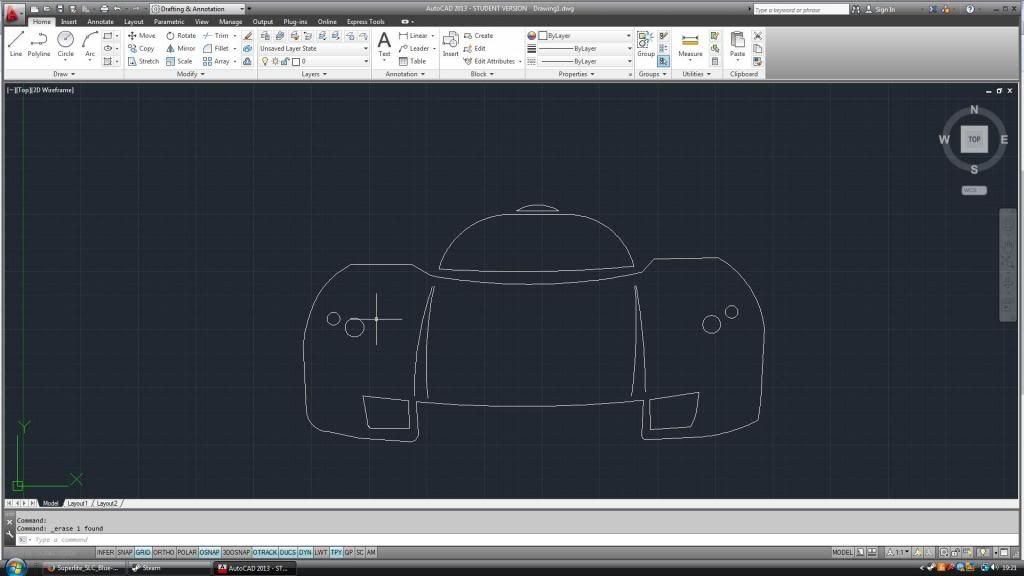

I just could not get it right. So that lead me to this.

I know the left air intake is a little messed up. I am also not sure on how to do the windshield area. The pic on which I traced. Has the doors open. I just was not sure how it would look. So I left them out. I could always draw some doors on later. I just wonder how I can make it better.

If you guys have any suggestions. I am open to any. Also so you know. I don't have a SLC or access to a SLC. I am just useing the pics I found on this site. If any one has high res pictures that they would like to share. I would not say no.

I wanted to do some thing like this. http://www.cartype.com/pics/5917/full/panamera_profile-art.jpg

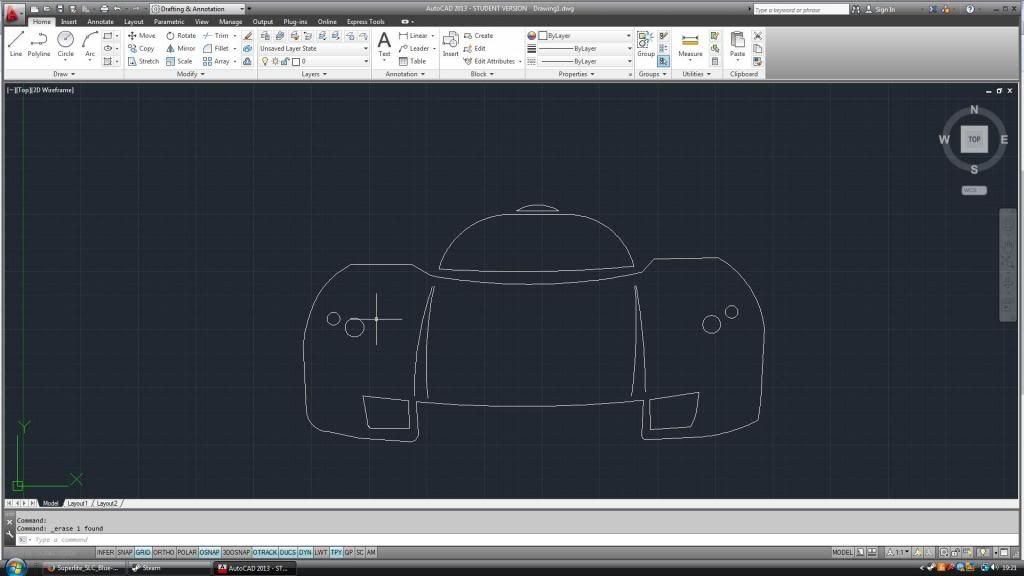

I just could not get it right. So that lead me to this.

I know the left air intake is a little messed up. I am also not sure on how to do the windshield area. The pic on which I traced. Has the doors open. I just was not sure how it would look. So I left them out. I could always draw some doors on later. I just wonder how I can make it better.

If you guys have any suggestions. I am open to any. Also so you know. I don't have a SLC or access to a SLC. I am just useing the pics I found on this site. If any one has high res pictures that they would like to share. I would not say no.

Last edited: