You're assuming Scott's going to be 'top ending' the car speed-wise, Les. But, perhaps he has no intention of 'going there'! (Maybe he'll 'chime in' on that.)

You're right, of course. 'Doesn't take much to screw a car's aero up (which is why I made reference to same). But, for ME, Scott's redo is nothing short of S-I-C-K!!!epper: I'd be just fine with owning a car that looks like that and keeping it 'under 100' if need be!!! :thumbsup::thumbsup:

Thanks for the compliment.

Just to clarify, if I had one smidgen of an idea that my design would have negative effects or generate lift at speed, I would not have gone through with it. I think any person in the know would have a hard time pointing to any one problem area. Granted, it has not been wind tunnel tested, but from my knowledge, neither has any other kit or component car that is used as a track mule or race car. In my opinion, a Cobra should be air born at anything over 120mph! haha

The only negative I see, is that the pinch area (between the fender and center nose) is that it is pretty aggresive and will speed the air up as it sqeezes through the upper channel, which can add to drag. Negatives I forsee almost none. On the positives side, I see greater force being applied to the side surfaces which can help keep the car straight at speed. The brand new Lemans Porsche has a similar pinch area between in the same spot. Only difference is it has a lower exit also.

At the end of the day, I have really spent months in the background designing the body to be as functional as possible, with looks falling to the second consideration. If there is a negative that I see, it will be lower top speed due to the more drag from downforce applied. Only an issue if racing for trophies on high top speed tracks. Solution to problem is= mo'powa! Lol.

To really simplify the design, I basically made two large canards with end plates. Look at the drop section to picture it. If anyone can argue that two canards that size mounted outside of body, with end plates at 30 degree angles will generate uplift, then LOTS of people have been doing it wrong! Hahaha. In my opinion, keeping them inboard and directing the airflow around the windshield and past the side windows, will clean up the air going down the side of the car, which will help the air flow through the side heat exchangers i have.

Lets not forget what will be happening with the front radiator air exit. Air will be traveling slower at that exit creating slight turbulence at the base of the window ( will have fins in there directing airflow too). That turbulence will be a buffer to the high speed air going over the car and up the windshield. In theory, it should reduce the drag going up the windshield, which is roughly 25-30% of your frontal area exposed to drag.

This was not directed to you Larry or anyone else. Just trying to explain abit of why I did what I did and the theories behind it. While I am very happy that lots of people like it visually, I did do months of research first. It wasn't something I just learned, but the culmination of 25 years of inspecting aero design on every single car with 4 wheels that I see along with much book learning.

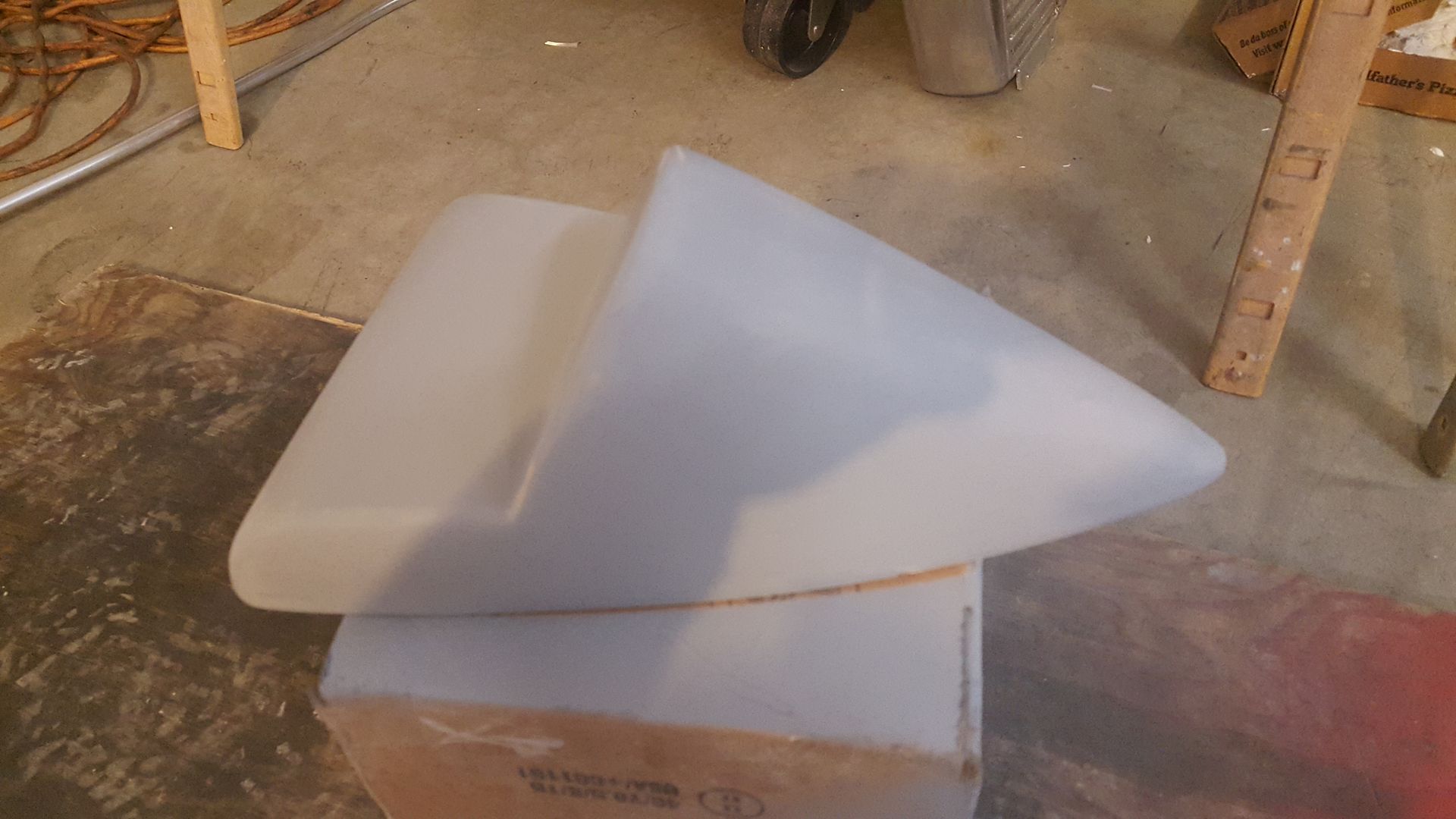

On a side note. If I do decide to make a mold and sell it, I have zero problem with having a competitive driver test the nose on the west coast, so I could drive it to them and be there for the testing at my expense. They just need to be a good enough driver to push it to get good comparisons on consistent lap times.

I also encourage any people that have experience in testing aero dynamics to speak up if they see a problem with the design. I do love a good technical debate. :thumbsup: If you do not have experience in this field, simply posting a picture of a flipping race car [that just crested a hill under acceleration while following a car generating dirty air in the rain (yes rain can be the factor since the water mixed with the air made the air more solid) and using it as a comparison] to possibly discredit the design, is along the lines of scare tactics. Keep it technical with good examples, and i have no problem listening and going into further detail.

So who wants to test it on the west coast? rockonsmile