Dodge Viper ACR?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scotts build thread

- Thread starter Scott R.

- Start date

I think that looks better than the previous design. You have great ideas.

Good morning Scott, How close are you back to the RCR headlight bucket? Your getting close aren't you? Keep up the cool work ! So far I like it all, good job.

The low beam location will be very close, but it will be vastly different. With the slope and relation to tire, there really is only one spot to put your low beam and keep height within reason. Thats about the only thing that will be similar.

I think that looks better than the previous design. You have great ideas.

Thanks Shawn. Hoping this one is a winner!

Yup, very close to what finished product will be. But, mixed with a bit of this too.

Be sure to check with your local vehicle regulations for minimum headlight height to be legal

In Oregon, I could probably get away with a candle on the roof, so not worried about here. Want to say Oregon is 20", but dot regs say 24". I assume there is some wiggle room with a kit/component car. With the 60mm housing, I will literally be near the exact same height of the original since it really is the highest, furthest back point you can go, unless an led housing was used and shallower depth.

I'm sure you know all to well what I am running into here for space. Lol.

I'm sure you know all to well what I am running into here for space. Lol.

I have pondered this type of light setup on my own car.

I have pondered this type of light setup on my own car.

You would have to redesign the fender all the way back to the tire to do it. But, it would open up to lots of different designs then.

Here is another one for you. 2017 Volvo Lemans concept.

Scott, your getting too good with glass fab work. Getting those edge inserts for the lenses had to be tricky.

Scott, your getting too good with glass fab work. Getting those edge inserts for the lenses had to be tricky.

Thanks Dan. There is ways to make quick work of it though. Once the old cut out was filled in and smoothed, it is a snap.

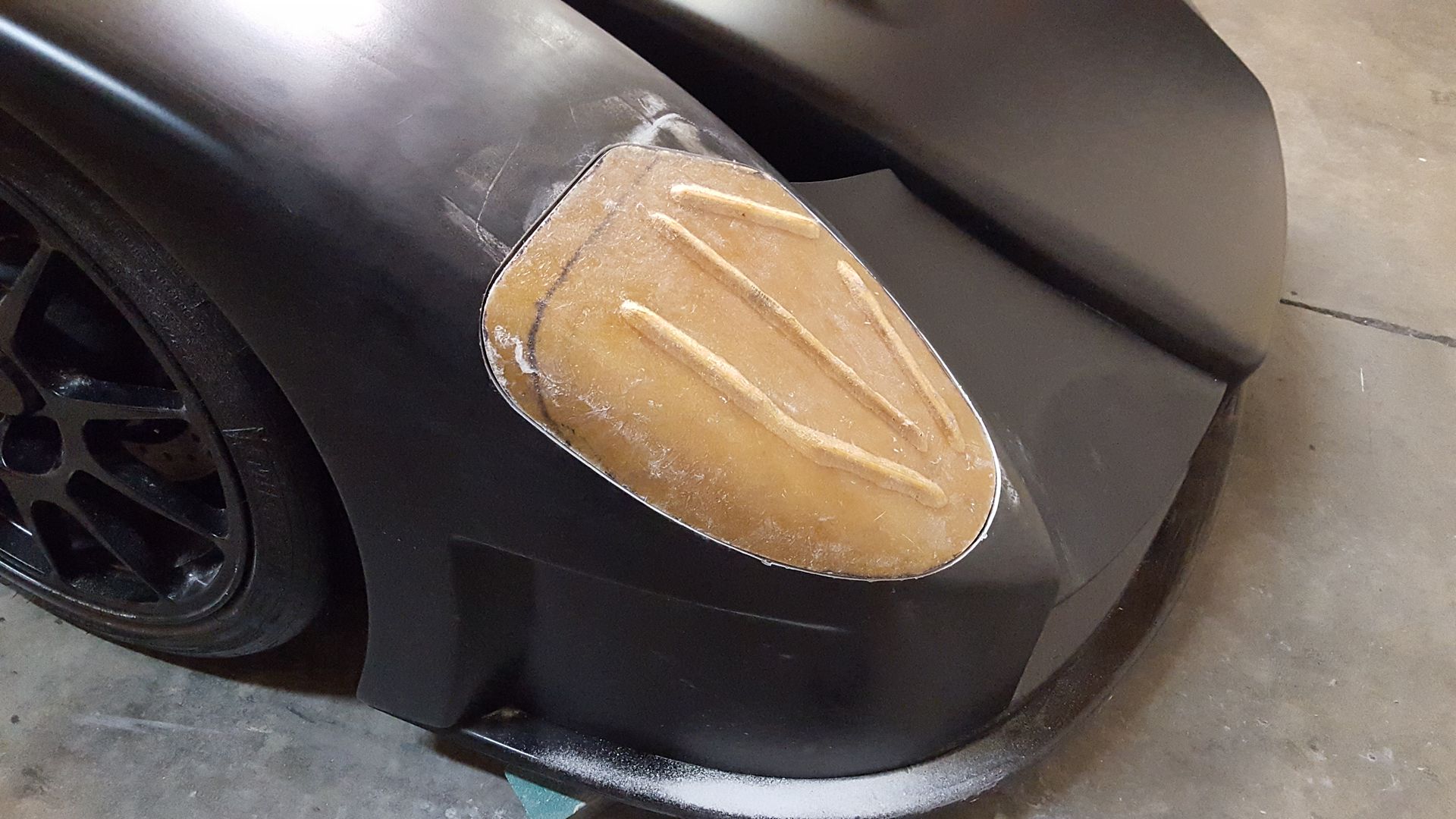

Headlight lens form is just some laminations laid up over fender to copy it. Since it is formed to the outer shape, it will transfer the shape to the outside of the plastic lens, so it should fit perfect and correct "bubble".

Then mark on fender your headlight lens outer dimensions. Then mark inside of that your flange width, I did an inch. Cut out the mark inside of the flange first, and drop the center section. Then cut out the flange to leave only the lens outside line. Because of the curve on the side, and the fact the flange will mount inside, it is just a touch smaller when mounted underneath and can be bonded in to make your flange. Little bit of bondo to smooth and radius the transition, and boom, done. Only a couple hours into what you see done, starting with a full fender and not cuts.

I usually spend a bit of time planning the mold/mock up process to make it as quick and effecient as possible. In all honesty, I hate fiberglass work! :laugh: Cool when it is done, but itchy as hell, messy as hell, dusty as hell, and I always seem to forget a mask.........for years now. Haha.

Similar threads

- Replies

- 5

- Views

- 490