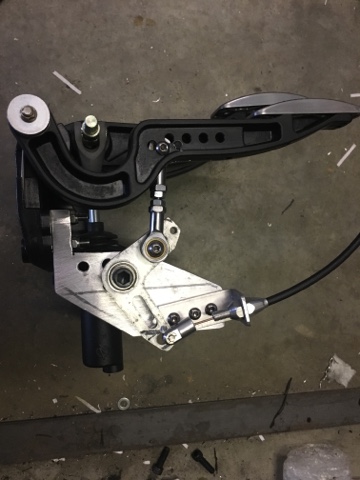

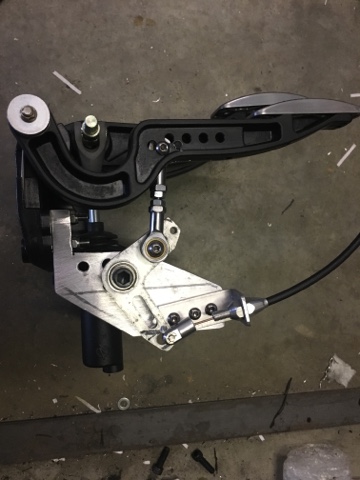

I am getting some little things done. I found and mounted my coolant overflow tank and also the oil catch can. Space is getting limited, that is for sure. I also mounted the radiator fans up front. I figured out my gas pedal as I am using a cable and had to come up with a bracket and crank arm situation. It took some doing, but here is what I came up with. I made it so I can have adjustments later for pedal stroke vs tb opening stroke. Now I am working on making my pedal base plate that can move via linear actuator. I have the actuator and figured out how I want it to work and ordered the alum for it.