Master......:fireman:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

slc Ls 376 and grazziano

- Thread starter silverback

- Start date

I received the pilot bearing [thanks Fran] and the arp flywheel bolts today. We now have everything to put the grazziano and Chevy together. We are swamped in the shop but I should be able to assemble this week or into the weekend, we realized at the last moment that we didn't have the install kit for the grazz, to the chassis, so a quick call, and Dean said he would ship it out today, Thanks Dean. I am great at taking pictures but I get an "F" at being able to load them on the forum. We will be working on that with the help of one of my family's little people who has no problem with that stuff she has been able to load them on my Facebook page [she set it up of course] with out issue. I will keep all of my fellow grazzianos informed ...m

Looks like Mahlon is blazing the trail. I will eagerly await the pictures and will be following close behind - thanks! :thumbsup:

The Grazzianno and the Chevy are done! The girls went to Thursday night football game I stayed in the shop and assembled the lot. The flywheel went on with little effort. The arps bolt shoulder was a little tight, but the fit was easy to adjust on the flywheel side. no issues with the clutch at all. before assemble of the clutch, I did a rough fit of the grazz to the ls which revealed a clearance issue with the oil pan The oil pan has to be modified to clear the front output shaft on the Grazzianno. Since the grazz is an all / 4 wheel drive transaxle the output snout sticks out beyond the adapter plate by about 5/8 inch. I didn't measure the amount because looking at the pan it was a pretty easy fix. The aluminum pan was no challenge for one of my bran new carbide bits cutting wax and a somewhat steady hand, after taking the two basically pieces of webbing or ridges that were in the way of the shaft down[ it probable took 5 minutes or less] another rough assemble revealed it will clear. My only thought was support of the shaft as it will spin but I am not going to worry about it for now, if it brakes we will fix it later. That seemed to be the only issue I ran across, the clutch assembled with out a problem. I had no alignment tool so I used one from the box o tools for a 911 Porsche which fit right in the bearing and lined it up in the splines of the clutch plates as it was not the right splines but by centering it in the discs I figured I would be close and the grazz slid right together. heavy little bugger measured the starter and it looked on the money so two bolts later I was done everything looks good .We will put it in as soon as the install kit arrives. Now to the pictures I did take them and we will figure out how to get them posted! I am not sure myself were the will end up but I will keep everyone interested, posted.....m

Alex I believe you are right, The area I had to clearance as well as anyone else who is running this same set up, and doesn't want to deal with it on the output shaft end I believe posses little risk. If cutting down those two pieces of webbing has a negative drastic effect on this Chevy I promise being a mostly ford person I will throw it out.......m

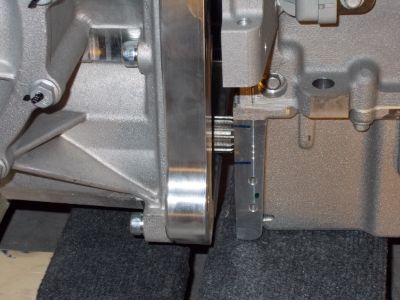

This is a picture of the front output shaft with clearance needed for the oil pan

http://s1015.photobucket.com/user/j...e-4fda-ae76-51eb43d1f6bf_zps785fe24e.jpg.html

Wouldn't it be better to just cut off the output shaft? It's not like you have a plan for running a driveshaft forward, is it??

15 minutes with an angle grinder and done.

I would love to make the slc all wheel drive! What scares me Is I was looking at the car and wondering just what would It take? I am always up for a challange, but I will let somone else do that one first. maybe Fran? Looked at both the shaft and the pan with my conclusion being the pan was a no brainer.......................m

Tom It is heavey cast aluminum, and as that I think it would add some strength to the engine block as a whole. I also would hope the engine was not depending on the oil pan for to much. I would not be afraid to fabricate a steal one if for some reason i had to to make things work. We are planning to use the slc for club events as well as street use and have it set up so far, somewhat aggressive. If It brakes we will have to fix it. I am still trying to figure out the stiffer spring rates and still use the lift for the front. I am told by a higher authority that it will be street legal......m

PeteB

GT40s Supporter

Have you asked Fran about the output shaft interference? I would think RCR would have test fit a Graz with an LS3.

You ever tried to cut an output shaft? Hardened steel is not easy to cut.

Wouldn't it be better to just cut off the output shaft? It's not like you have a plan for running a driveshaft forward, is it??

15 minutes with an angle grinder and done.

You ever tried to cut an output shaft? Hardened steel is not easy to cut.

I did a search on the Autopartsway.com website for clutch alignment tool G126940 and it came back with this: http://www.autopartsway.com/search....allSmd/allEn/allB/allCT/allsct/search:G126940 : a "Mr. Gasket Co." #6940 clutch alignment tool.

It arrived today, but unfortunately, it doesn't fit.

It is too large to fit through the splines of the clutch plate and in any event, is a 10 spline tool, whereas the clutch looks like it has 25 splines.

If anyone has found an alignment tool that fits, please post here and let us know.

Thanks.

It arrived today, but unfortunately, it doesn't fit.

It is too large to fit through the splines of the clutch plate and in any event, is a 10 spline tool, whereas the clutch looks like it has 25 splines.

If anyone has found an alignment tool that fits, please post here and let us know.

Thanks.

I did a search on the Autopartsway.com website for clutch alignment tool G126940 and it came back with this: AutoPartsWAY.com - - G126940 - Buy - G126940 Online : a "Mr. Gasket Co." #6940 clutch alignment tool.

It arrived today, but unfortunately, it doesn't fit.

It is too large to fit through the splines of the clutch plate and in any event, is a 10 spline tool, whereas the clutch looks like it has 25 splines.

If anyone has found an alignment tool that fits, please post here and let us know.

Thanks.

This one looks like it fits:

Performance Parts & Repair Experts for Audi, Porsche, and VW - Clutch Alignment Tool - TLS-33-36

23 splines, and supposed to be for the R8.

I'm a little worried about the "23 splines" reference on that tool. I double checked and still count 25 splines on the clutch plates and on the shaft of the Graziano.

Has anyone successfully used this one or found an alternative that they know works?

Has anyone successfully used this one or found an alternative that they know works?

Last edited:

Dave I as I said what worked for me was just one that I had for a Porsche 911. It is the proper size to fit the bearing and smaller then the splines of the clutch discs [it fits right inside w/o any contact] I just centered It I the middle of the discs torqued the assemble down and the grazianno went right in. I don't think It would be an issue doing It again....m

Similar threads

- Replies

- 27

- Views

- 11K

S

- Replies

- 8

- Views

- 4K

S

- Replies

- 0

- Views

- 21K

- Replies

- 74

- Views

- 13K