Ed McClements

Supporter

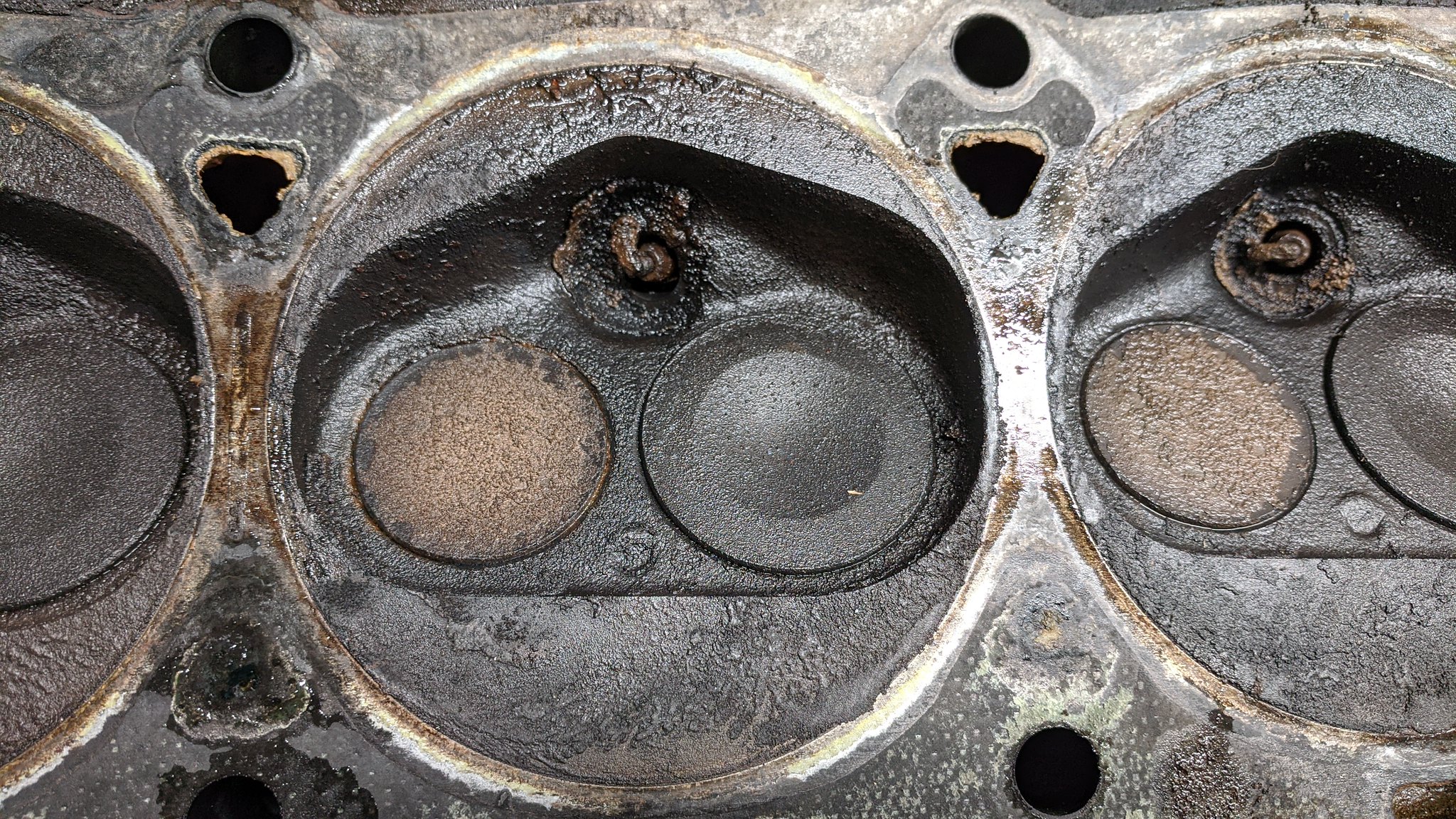

As mentioned in my build thread, I recently bought a '69 302 for rebuild:-

Which looks like a '68-style casting, but poured in March '69? Go easy on me if I've got this wrong! Aluminium tag is still in place, which makes me think it's not been apart, but what about these threaded gallery plugs...

which would have been pressed-in brass(?) plugs from the factory...right?

I made a start on disassembly today, and thought I'd share the gory details...we all like threads with pics, right? Carb, dizzy, fuel pump all came away very easily, after a coating of release fluid yesterday.

The waterpump has some crud, but next to no corrosion - the seller said that the coolant was fresh with green anti-freeze, and that the oil was clean. Take that for what it's worth, but so far the condition bears out this story.

Inlet manifold next; needed a hefty whack with an aluminium drift under the thermostat housing to unstick it from the heads, but it then came away cleanly.

The inlet faces on both heads seem not to have seen daylight for over 50 years; where the gasket came away with the manifold is a clean casting. Lifter valley seems in good shape, too - no baked-on oil or sludge yet.

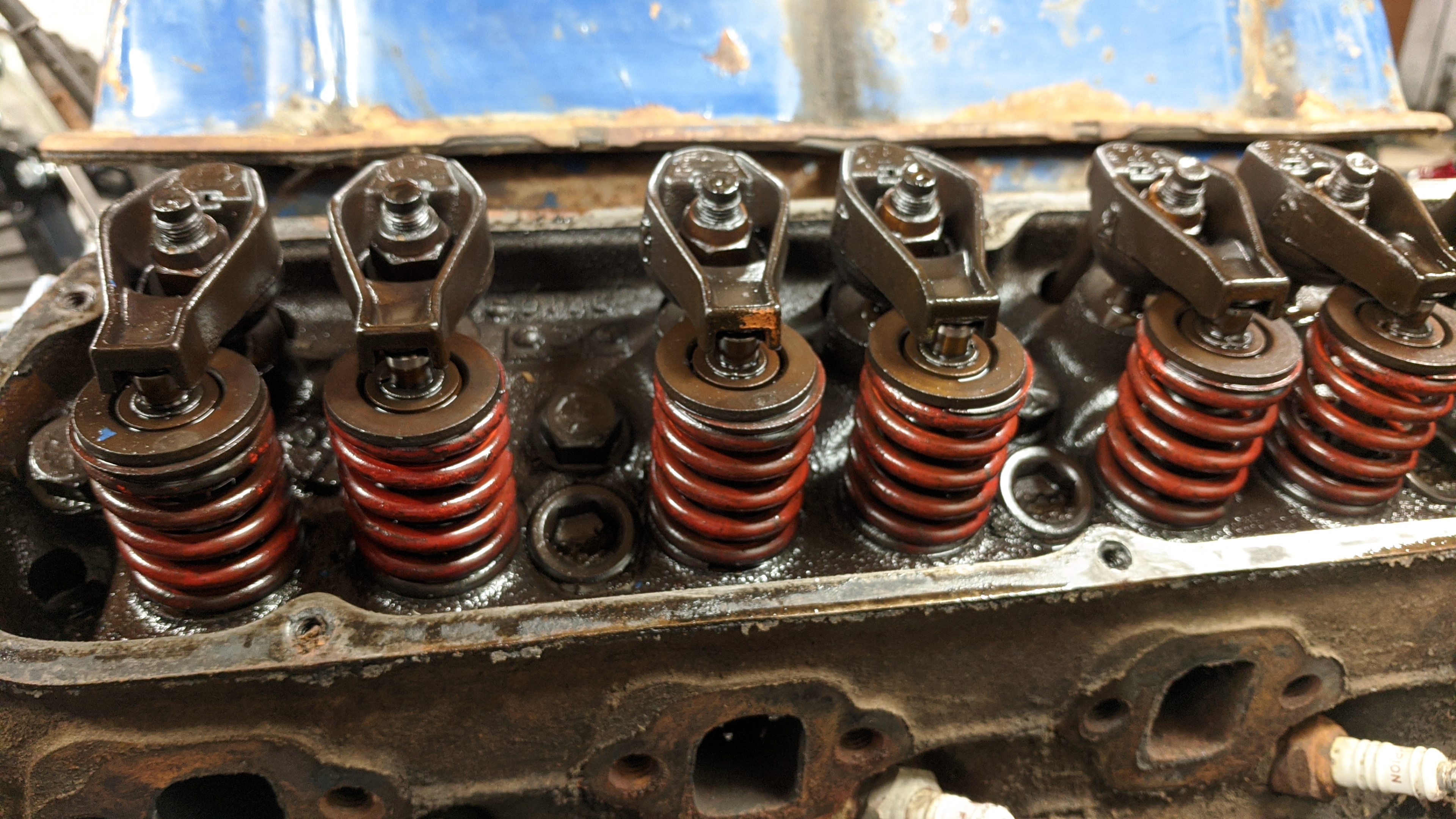

And this the view from under the rocker covers...

Opinions welcome from anyone who has torn down one of these engines...does this look OK so far?

Which looks like a '68-style casting, but poured in March '69? Go easy on me if I've got this wrong! Aluminium tag is still in place, which makes me think it's not been apart, but what about these threaded gallery plugs...

which would have been pressed-in brass(?) plugs from the factory...right?

I made a start on disassembly today, and thought I'd share the gory details...we all like threads with pics, right? Carb, dizzy, fuel pump all came away very easily, after a coating of release fluid yesterday.

The waterpump has some crud, but next to no corrosion - the seller said that the coolant was fresh with green anti-freeze, and that the oil was clean. Take that for what it's worth, but so far the condition bears out this story.

Inlet manifold next; needed a hefty whack with an aluminium drift under the thermostat housing to unstick it from the heads, but it then came away cleanly.

The inlet faces on both heads seem not to have seen daylight for over 50 years; where the gasket came away with the manifold is a clean casting. Lifter valley seems in good shape, too - no baked-on oil or sludge yet.

And this the view from under the rocker covers...

Opinions welcome from anyone who has torn down one of these engines...does this look OK so far?