Mike,

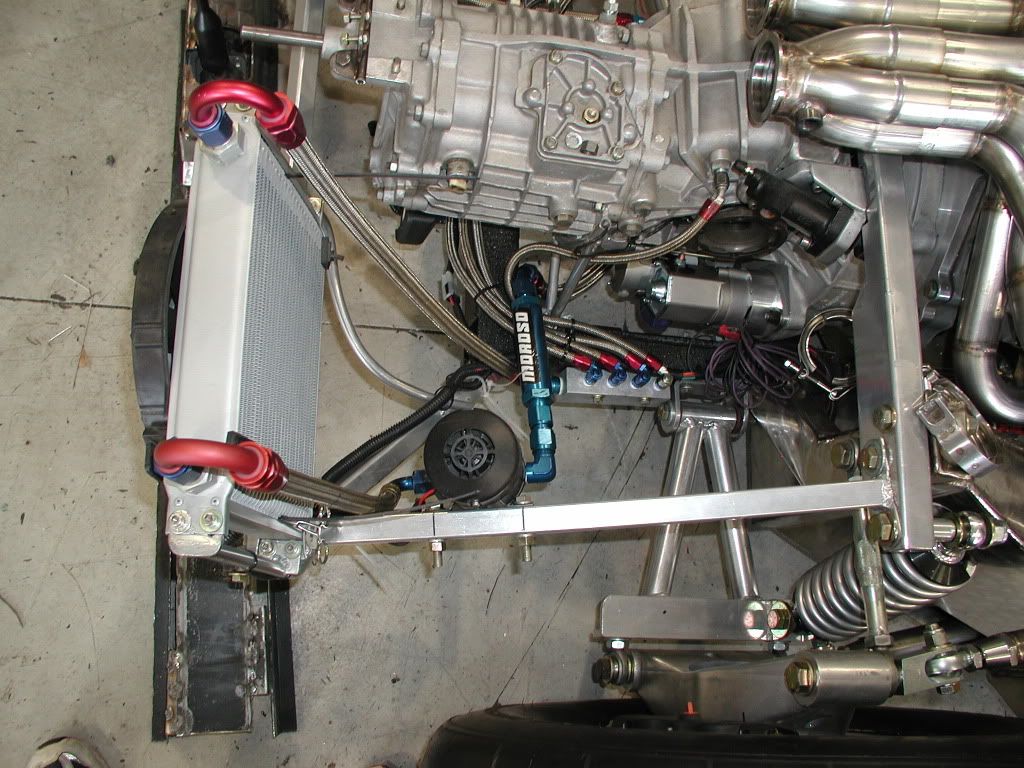

I have the 930. My Porsche shop foreman told me that a cooler and spray bar isn't really needed. Most of the race cars don't bother to use them. If they do the cooler is usually the one supplied by Porsche. Because the temps in the rear clip can get rather of hot, I wanted an oil cooler to the rear vent area of my 40.

Since I did that, the other bay looked out of balance.

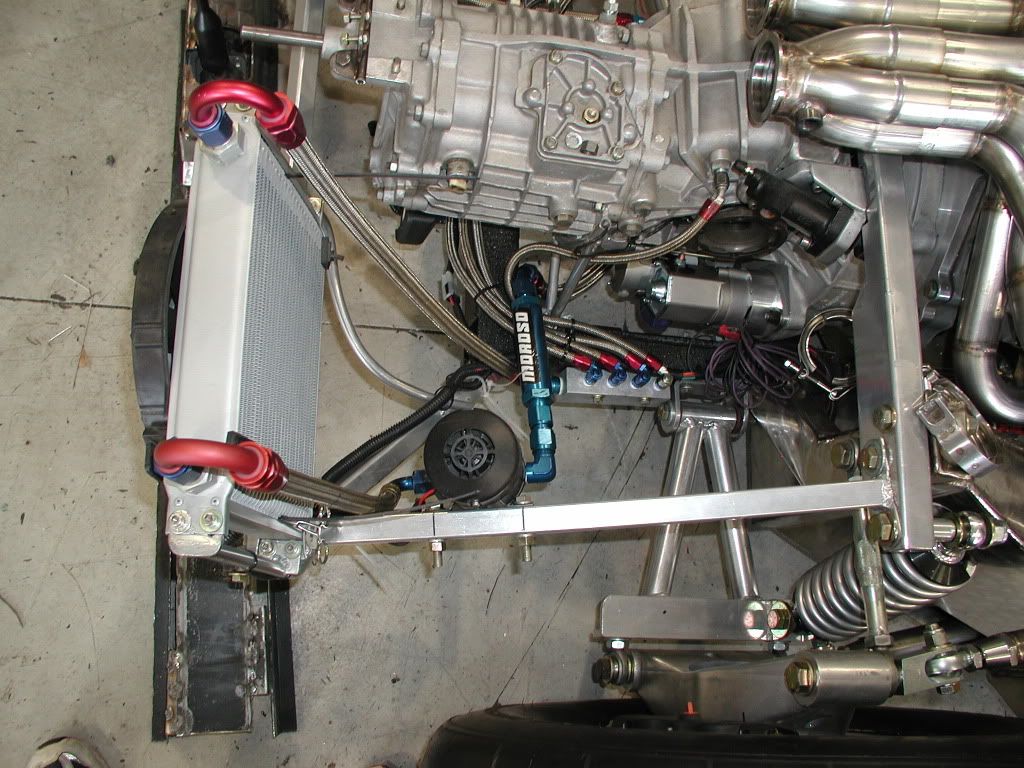

So I added a cooler to the trans.

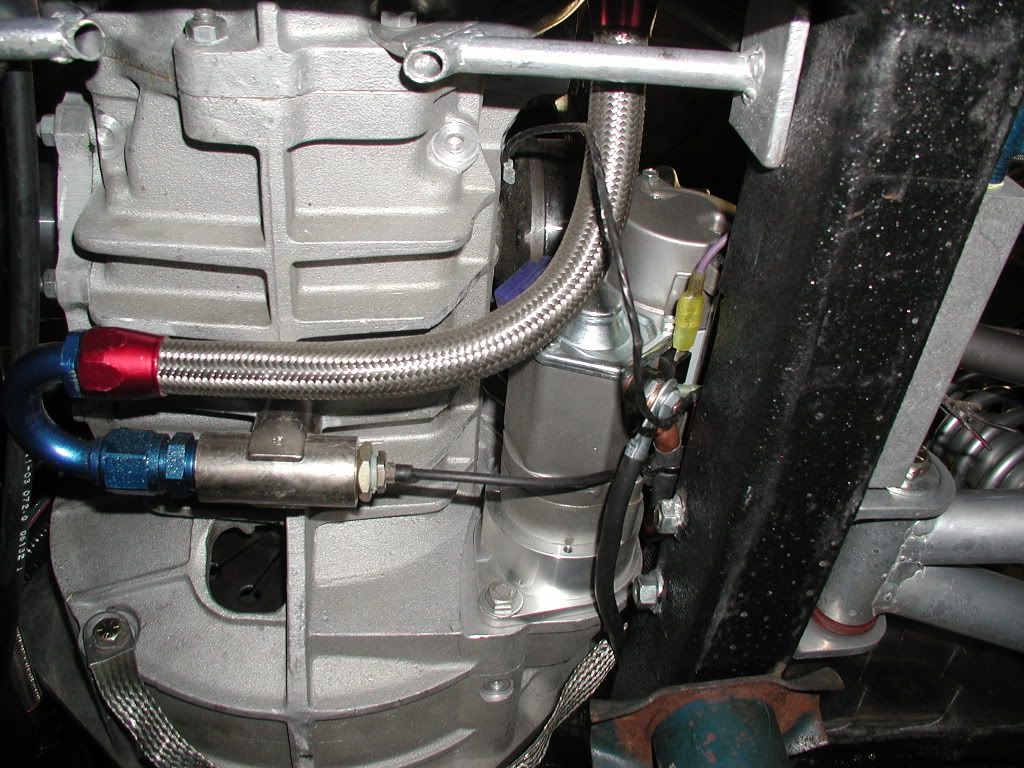

Then, we struggled with where do we put the return line. The only real option was to use the old drain plug. Routing it there, the gears wouldn't get the same treatment as the ring gear, With that, we decided to add the spray bar and besides, it looked kinda cool. Here is the meat of the system, pump, filter, thermostat, and the spray bar system. The lines go to 2nd, 3rd, 4th gears(see the first photo), and the ring and pinion.

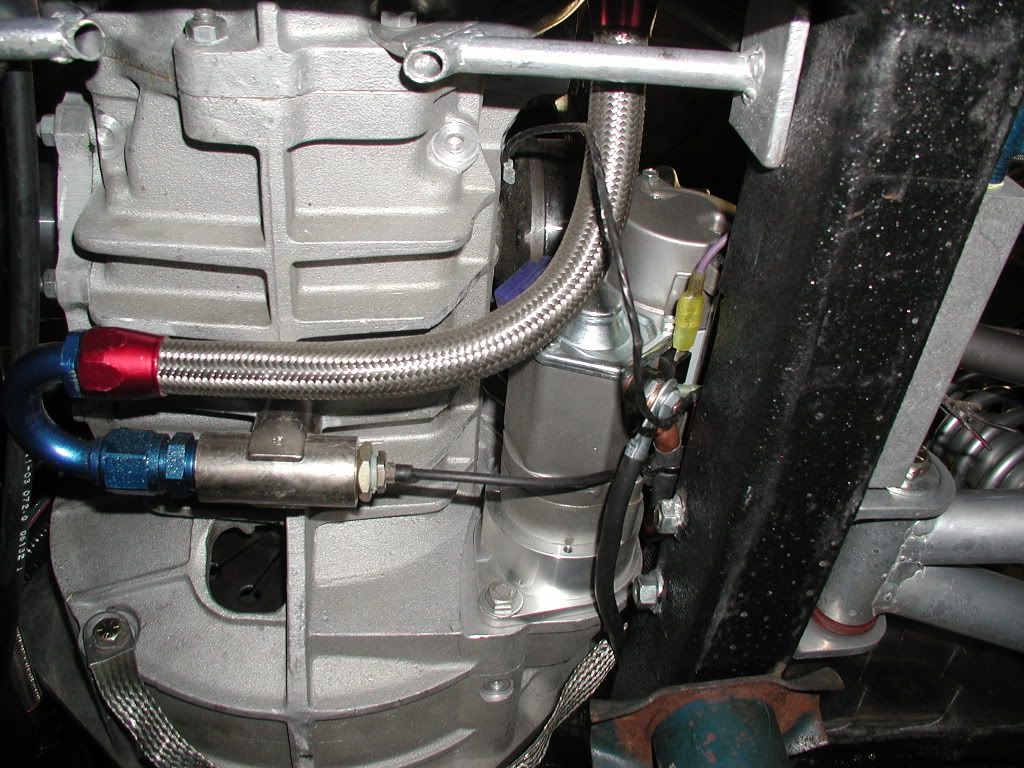

Here is how we hooked up the once fill hole, now the drain plug

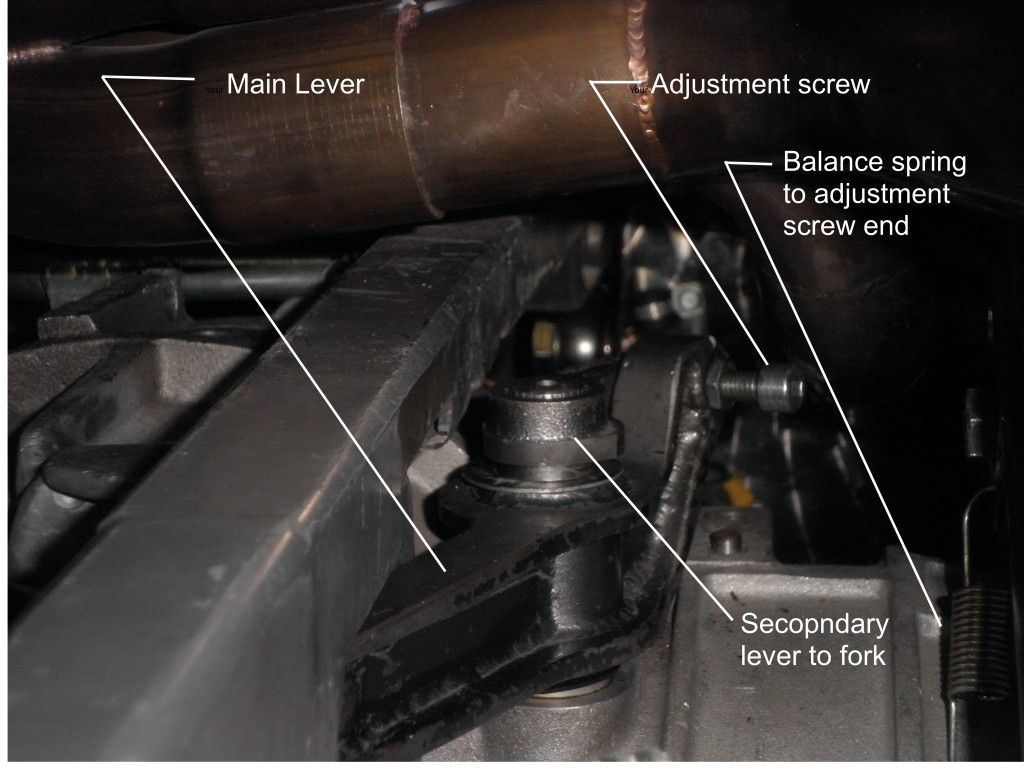

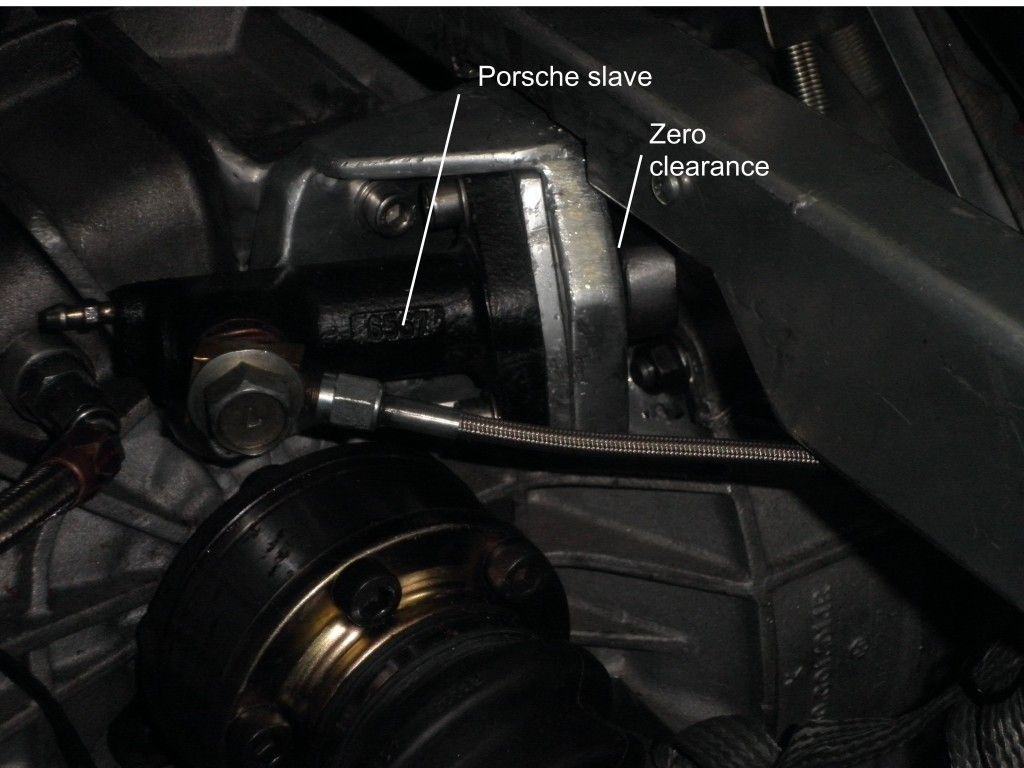

With mine, I decided to go with the conventional slave(pusher) and it worked out nicely. The amount of travel required is a little touchy on these setups. It is a balance between length of throw,slave/master cylinder sizing and how hard and far do you want to push.

Bill

I have the 930. My Porsche shop foreman told me that a cooler and spray bar isn't really needed. Most of the race cars don't bother to use them. If they do the cooler is usually the one supplied by Porsche. Because the temps in the rear clip can get rather of hot, I wanted an oil cooler to the rear vent area of my 40.

Since I did that, the other bay looked out of balance.

So I added a cooler to the trans.

Then, we struggled with where do we put the return line. The only real option was to use the old drain plug. Routing it there, the gears wouldn't get the same treatment as the ring gear, With that, we decided to add the spray bar and besides, it looked kinda cool. Here is the meat of the system, pump, filter, thermostat, and the spray bar system. The lines go to 2nd, 3rd, 4th gears(see the first photo), and the ring and pinion.

Here is how we hooked up the once fill hole, now the drain plug

With mine, I decided to go with the conventional slave(pusher) and it worked out nicely. The amount of travel required is a little touchy on these setups. It is a balance between length of throw,slave/master cylinder sizing and how hard and far do you want to push.

Bill