You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Interesting block strength video

- Thread starter MikeP

- Start date

Terry Oxandale

Skinny Man

Takes a while to get through some simple concepts, but well worth watching. Always believed in girdles. Thanks for the posting.

Neil

Supporter

Thank you for posting David Vizard's video. He lived here in Tucson at one time; I regret never having met him then.David Vizard Youtube video about Ford 302 block strength.

Cheers

Mike

Doc Watson

Lifetime Supporter

did they test a Mexican 302???

Neil

Supporter

Mentioned.did they test a Mexican 302???

Doc Watson

Lifetime Supporter

Just watched it .... very interesting, so my next question is....

Who is going to pour concrete down their water jackets...... common fess up!!!!! I know your watching Frank ;-)

Who is going to pour concrete down their water jackets...... common fess up!!!!! I know your watching Frank ;-)

Bill Kearley

Supporter

Neil might Doc. He may have been into drag racing

I'm surprised they don't do a bottom end arrangement like the way BMW do it. all the caps and girdle as one piece. given all the effort to machine and make the caps fit, i would have thought it would have been just as easy to join the lot together as one unit and pick up the pan rail as well.

BMW ///M3 S65 Bottom end. the S85 is the same but with 2 more rods.

BMW ///M3 S65 Bottom end. the S85 is the same but with 2 more rods.

Neil

Supporter

I probably would have if I had gone the nitromethane route.Neil might Doc. He may have been into drag racing

I recall that Repco did something like that with the Buick/olds/Rover V8 they developed for F1I'm surprised they don't do a bottom end arrangement like the way BMW do it. all the caps and girdle as one piece. given all the effort to machine and make the caps fit, i would have thought it would have been just as easy to join the lot together as one unit and pick up the pan rail as well.

BMW ///M3 S65 Bottom end. the S85 is the same but with 2 more rods.

a quick google.....

from here

‘RB620’ V8: Building The 1966 World F1 Champion Engine…by Rodway Wolfe and Mark Bisset | primotipo...

I think this was possible as the Olds block looks to have a deeper skirt than the Windsor. The Windsor block finishes about 1/8" below the crank cap split line. So if you were making a girdle it would need to be a significant casting.

from here

‘RB620’ V8: Building The 1966 World F1 Champion Engine…by Rodway Wolfe and Mark Bisset | primotipo...

I think this was possible as the Olds block looks to have a deeper skirt than the Windsor. The Windsor block finishes about 1/8" below the crank cap split line. So if you were making a girdle it would need to be a significant casting.

a quick google.....

from here

‘RB620’ V8: Building The 1966 World F1 Champion Engine…by Rodway Wolfe and Mark Bisset | primotipo...

I think this was possible as the Olds block looks to have a deeper skirt than the Windsor. The Windsor block finishes about 1/8" below the crank cap split line. So if you were making a girdle it would need to be a significant casting.

Make a plate that fits all the boltholes at block bottom, replace main bearing bolts with studs, measure distance between girdle and caps, make spacers, tighten with liquid gasket between. Have to make some mumbo jumbo custom oil pan.

Mike Pass

Supporter

This is what we used to do on Imp 998cc race engines. I used to make ally blocks to go between the steel plate and the main caps. Tuftrided the standard 3 bearing crank and stress relieved and shot peened the standard rods plus forged race pistons. Revved to 10,000rpm and 120+hp from 998cc back in the early 1970s. Not bad for a 2 valve per cylinder engine.

Cheers

Mike

Cheers

Mike

Mike, so on this engine with 3 main bearing crank you has 1-2 4-3 ignition order?This is what we used to do on Imp 998cc race engines. I used to make ally blocks to go between the steel plate and the main caps. Tuftrided the standard 3 bearing crank and stress relieved and shot peened the standard rods plus forged race pistons. Revved to 10,000rpm and 120+hp from 998cc back in the early 1970s. Not bad for a 2 valve per cylinder engine.

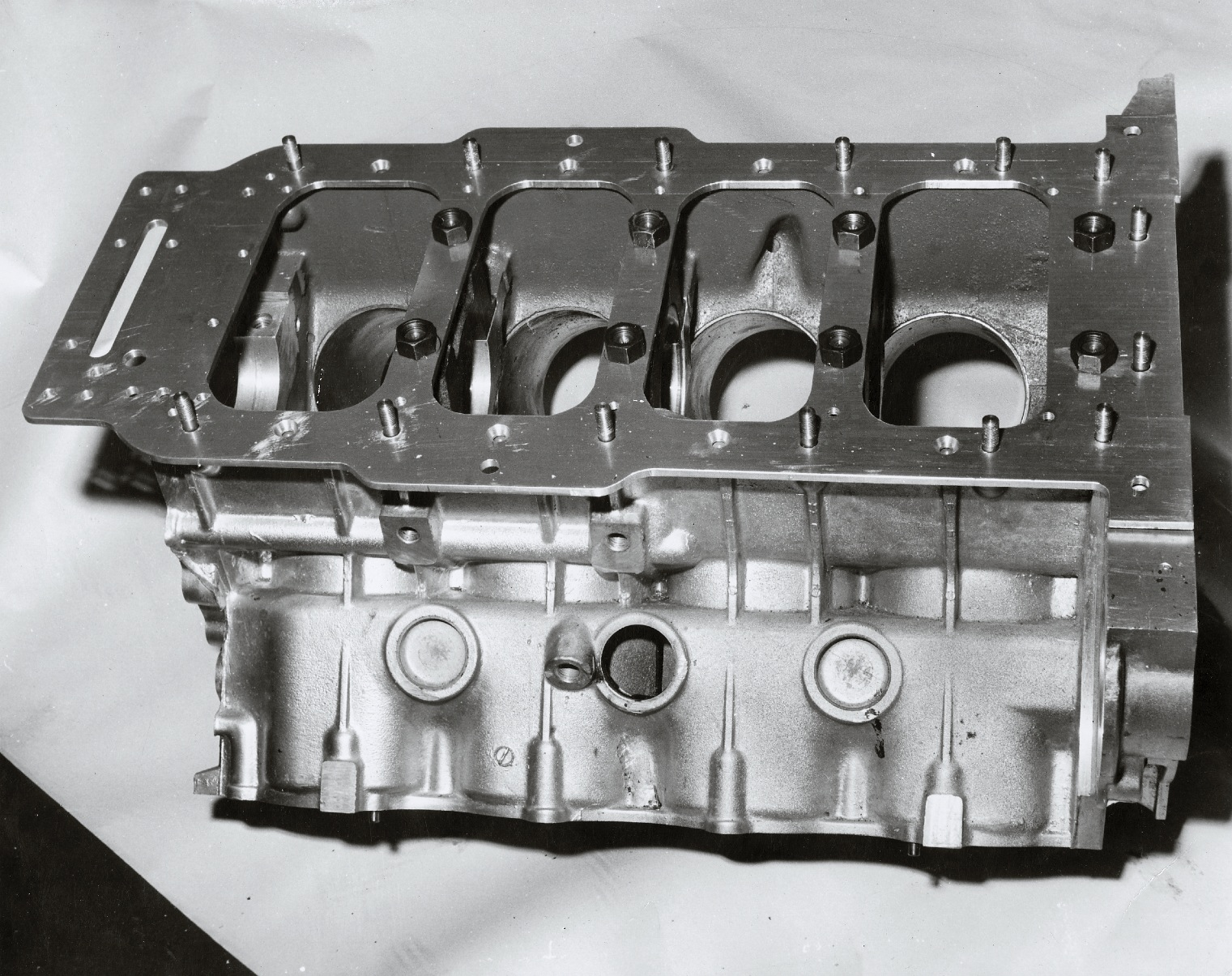

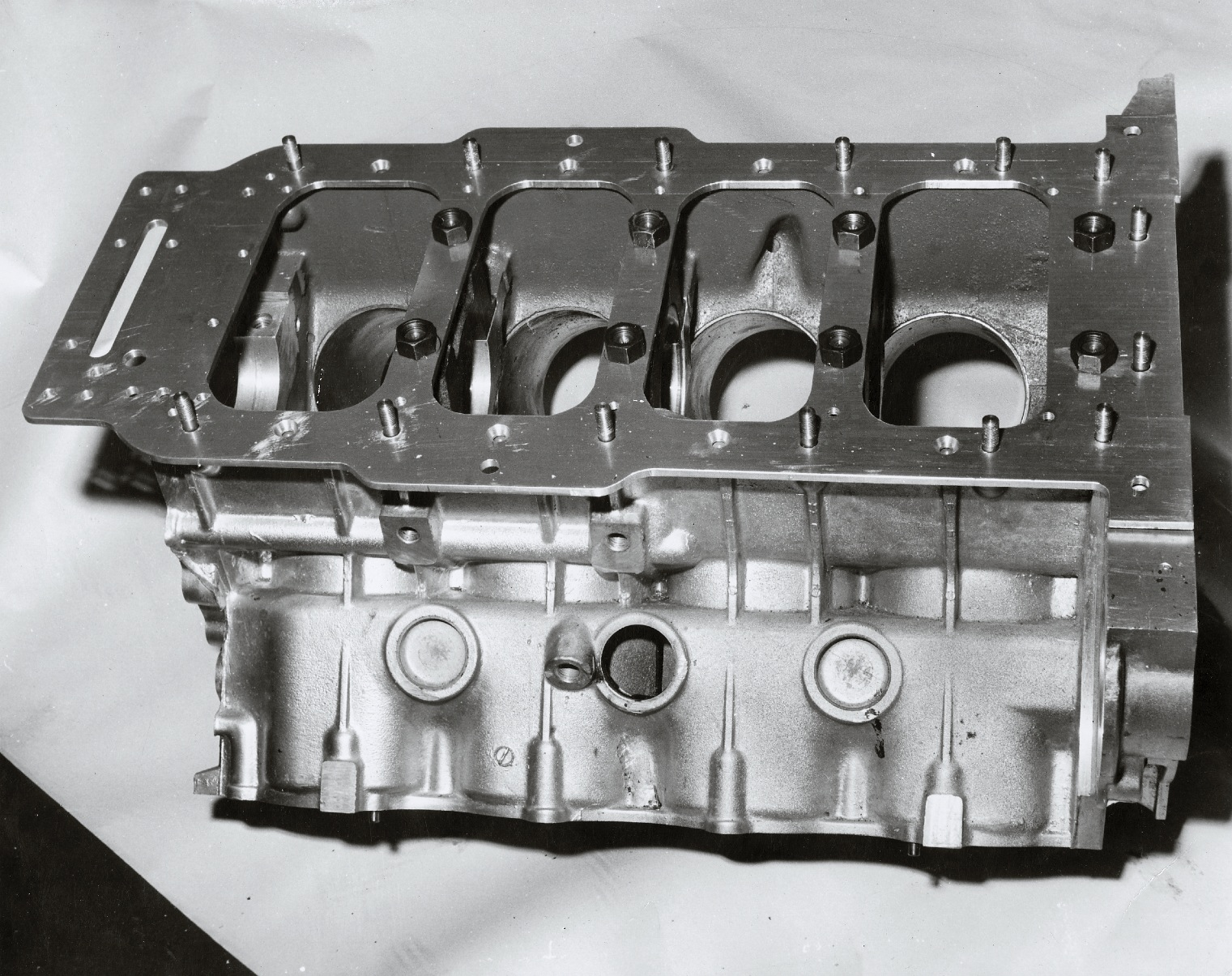

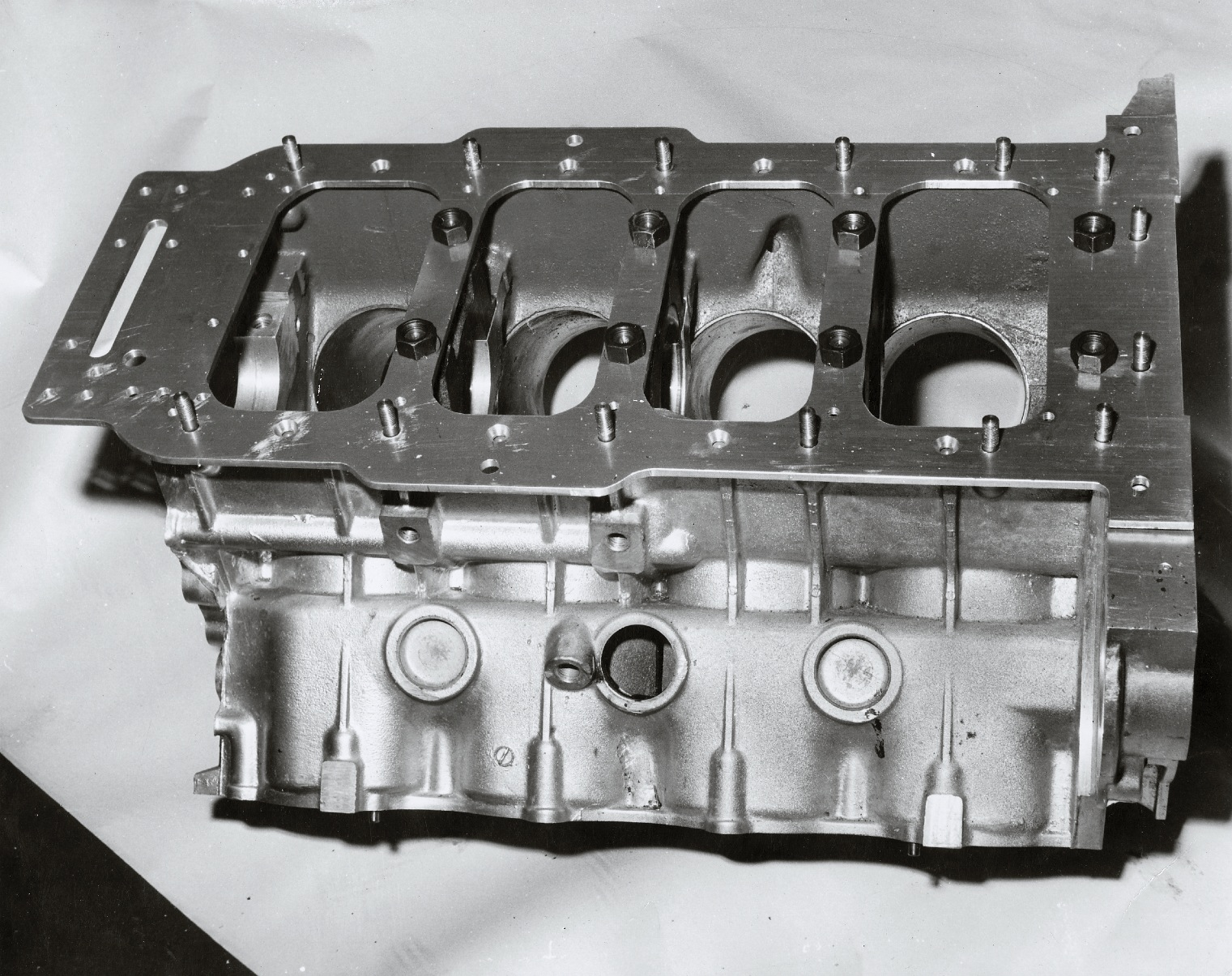

View attachment 127184

Cheers

Mike

Paul

I'm surprised they don't do a bottom end arrangement like the way BMW do it. all the caps and girdle as one piece. given all the effort to machine and make the caps fit, i would have thought it would have been just as easy to join the lot together as one unit and pick up the pan rail as well.

BMW ///M3 S65 Bottom end. the S85 is the same but with 2 more rods.

Tmeyer is currently designing and building a two part oil pan for their 'new blocks' which incorporates main caps and girdle etc. They arent exactly speedy though

The reference to concrete in the water jackets surprised the hell out of me. I would worry about cooling and pieces fracturing off and traveling through the rest of the system. Concrete grit couldn't be good for water pump impellers, thermostats, or radiators.

Terry Oxandale

Skinny Man

I believe that (concrete filling) was more for drag racing in that the short runs didn't challenge the cooling as much.

Similar threads

- Replies

- 39

- Views

- 2K

- Replies

- 0

- Views

- 240

- Replies

- 24

- Views

- 2K