Hi all,

Looking for a little help with the layout of my oil cooler set up.

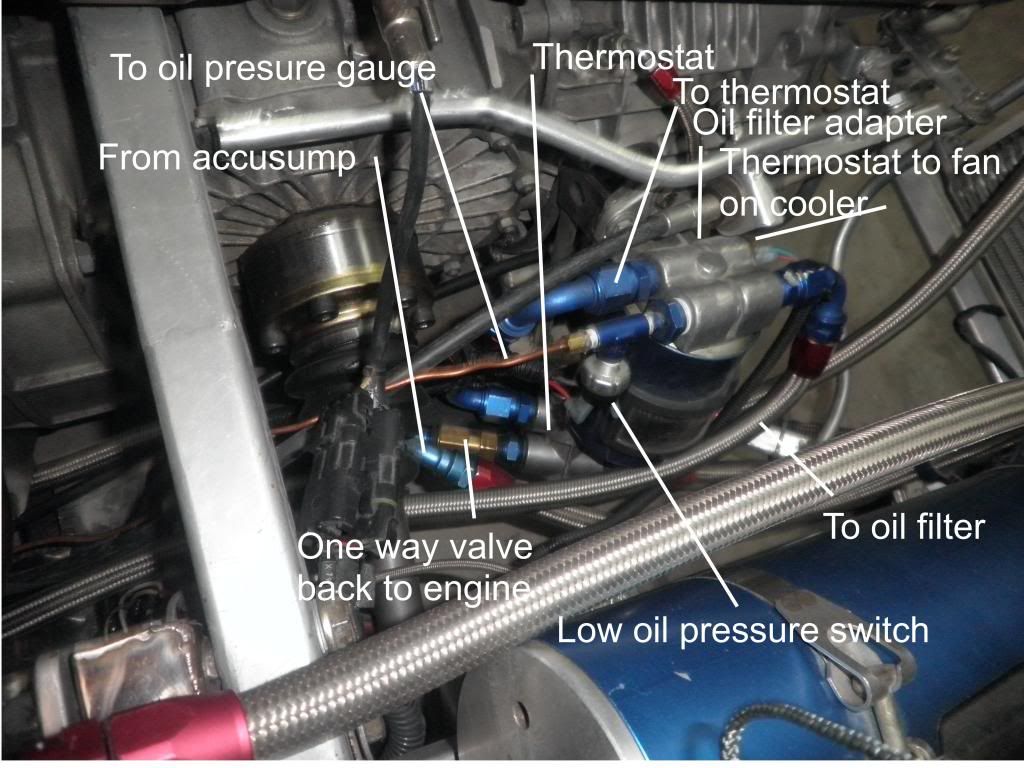

Basically, my car has an existing modest sized oil cooler run directly off a sandwich plate at the oil filter on the block. What I'd like to do is a) install a remote oil filter, and b) add a second (larger) oil cooler in series.

So, should the plumbing go like the following?

1. remote oil filter adapter on the block,

2. -10 (or maybe -12) supply/return lines to the remote oil filter from the block adapter,

3. sandwich plate on the remote filter with supply/return lines going to the two oil coolers in series.

Is there a different/better configuration than this?

Related questions:

1. Should I use -10 AN or -12 AN lines? -10 looks a little small in diameter to me for a SBF stroker.

2. If I incorporate a thermostat in the plumbing I presume that goes downstream of the sandwich plate at the remote filter mount, correct?

3. If I incorporate a thermostat in the plumbing what temp should the thermostat be? 195? 210? 225?

Thanks in advance for any help on this one.

Looking for a little help with the layout of my oil cooler set up.

Basically, my car has an existing modest sized oil cooler run directly off a sandwich plate at the oil filter on the block. What I'd like to do is a) install a remote oil filter, and b) add a second (larger) oil cooler in series.

So, should the plumbing go like the following?

1. remote oil filter adapter on the block,

2. -10 (or maybe -12) supply/return lines to the remote oil filter from the block adapter,

3. sandwich plate on the remote filter with supply/return lines going to the two oil coolers in series.

Is there a different/better configuration than this?

Related questions:

1. Should I use -10 AN or -12 AN lines? -10 looks a little small in diameter to me for a SBF stroker.

2. If I incorporate a thermostat in the plumbing I presume that goes downstream of the sandwich plate at the remote filter mount, correct?

3. If I incorporate a thermostat in the plumbing what temp should the thermostat be? 195? 210? 225?

Thanks in advance for any help on this one.