Finally today the phone stopped ringing and was able to get a couple hours in on car.

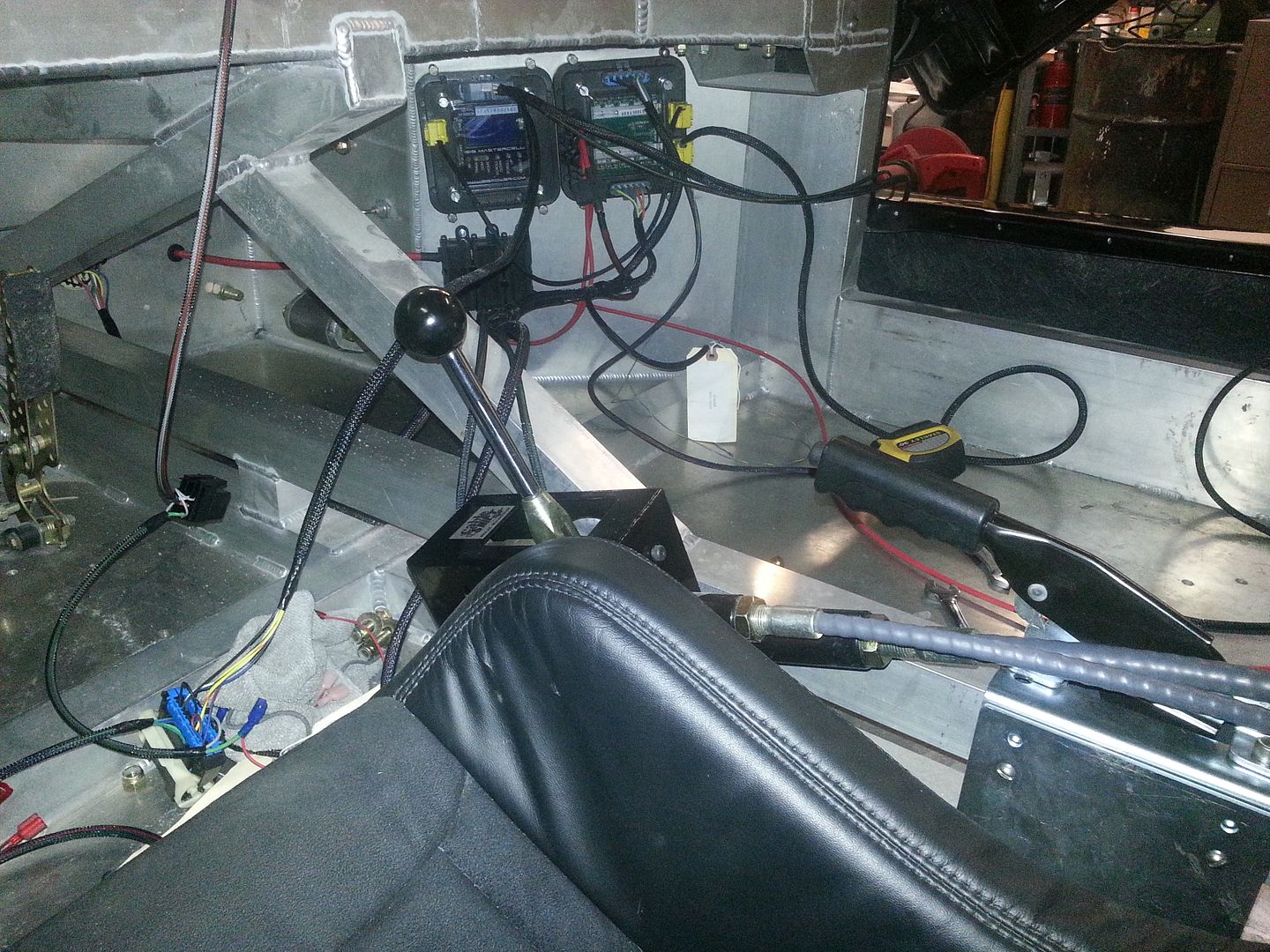

Parking brake lines finally mounted and cables inside car. My cables were not long enough so I had some other s.s. cable in the garage and tig welded some length on to them. After the weld I put heat shrink on the cables themselves to eliminate any chaffing to shifter cables and/or alum gas tank. Now, time to decide on handle location and then I gots some stops!

riv-nuts into alum and fastened bracket. Should be very solid. Shifter cables are tight as a guitar string right now, so will be remounting shifter. Looking at the later model chassis, I will be redoing some of the bars inside of the cockpit to make better mounting position for shifter and more room for center console and dash layout.

Parking brake lines finally mounted and cables inside car. My cables were not long enough so I had some other s.s. cable in the garage and tig welded some length on to them. After the weld I put heat shrink on the cables themselves to eliminate any chaffing to shifter cables and/or alum gas tank. Now, time to decide on handle location and then I gots some stops!

riv-nuts into alum and fastened bracket. Should be very solid. Shifter cables are tight as a guitar string right now, so will be remounting shifter. Looking at the later model chassis, I will be redoing some of the bars inside of the cockpit to make better mounting position for shifter and more room for center console and dash layout.