BTW, Here is me and my assistant pondering this build.

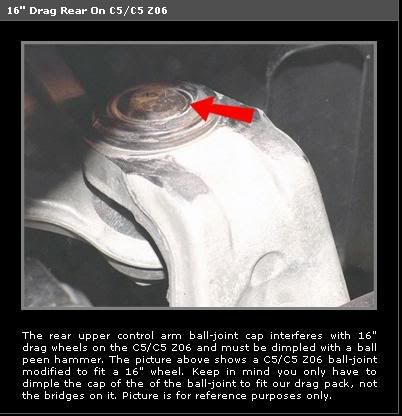

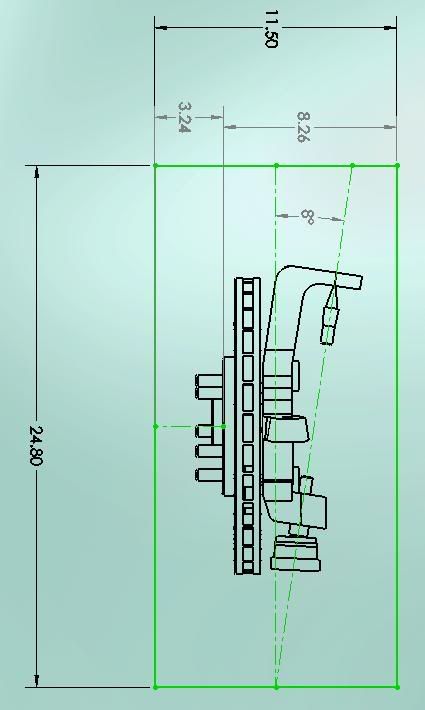

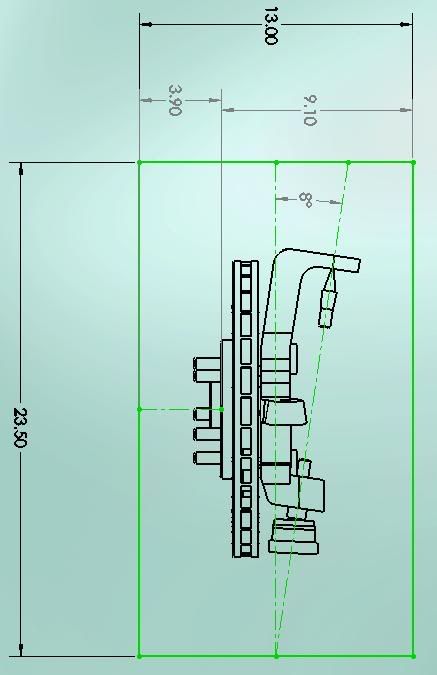

I've been trying to determine what I want to do about wheels/tires and brakes for this project. From my research, I can run as small as 16" diameter wheels with C5 uprights.

Justin

Justin if you're interested email address is [email protected]. Its a .dwg Rhino 3d file in its present state, but if that wont work in your CAD then i can give you the raw data i input to get the pickup points. Mind you these are not finished cad files just simply the geometry of the suspension for a C5 corvette.