Maybe, heading to the dyno in a few days.

I nboticed 2 things

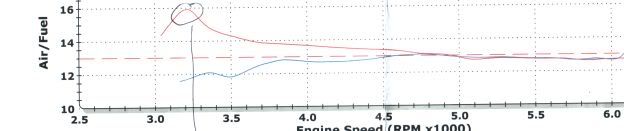

- lean stumble from last dyno. HOWEVER, this stumble only happened if dyno'ing in 4th. If we dyno'd in 5th, my a/f was a solid 12.7 to 12.9 througout the entire run (probably because in 4th at 3000RPM it's like FUEL ... NOW!!!!! WTF??? FUEL!!!!!!!!! ; in 5th it's slower to rev so it starts the run at 2000 and by the time it hits 3000 it's like 'okay, fuel now please...oh, hello fuel')

- when starting aggressively, the more throttle I gave it, the worse the performance. if i dumped the clutch and gave 1/8 throttle, rev'd up to 6500 and shot forward. if I repeat but with 1/2 throttle, it'd rev to 2500ish, pause for a split second, then shoot up to 6500.

4150hps come with the pink cam (2nd most aggresive cam), and a 28/29 nozzel ..... was told 28/29 was kind of dinky for my setup, so I tried a 35, which made it much much better. No lag down-low,and I can't feel any stumble anymore.

But here's my question - how do you know when to stop increasing nozzel size? From what I've read, more is not better (makes sense). Should I stop at 35 since the stumble/hesitation on aggressive start is gone, or try higher like 40?

Should I change the pink cam to the 2nd position, or try the black cam, or just leave it alone if everything is feeling fine at the moment?