Howard Jones

Supporter

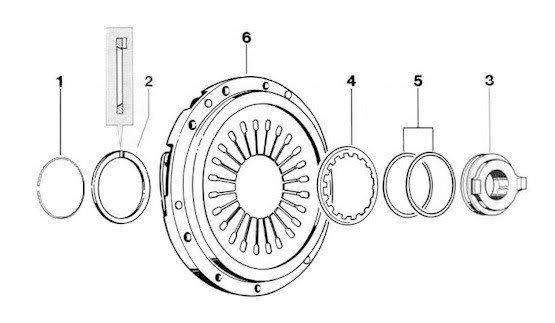

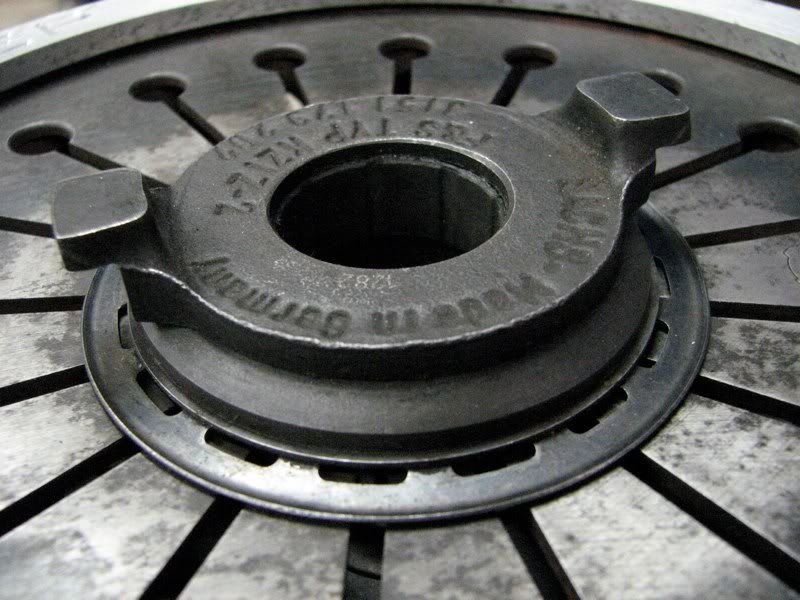

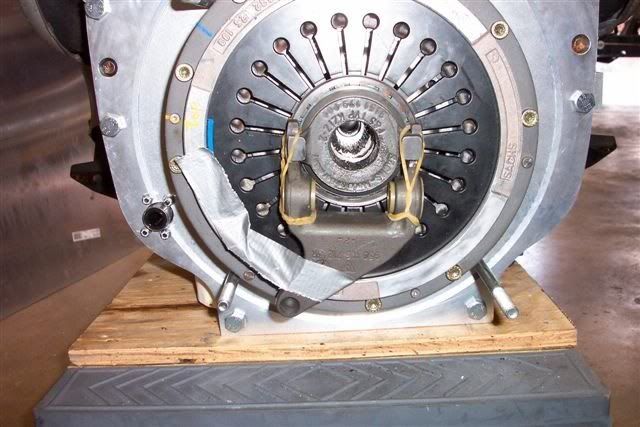

I am looking at my brand new Sachs clutch and I haven't a clue where to start. I believe it is a turbo type and it a hydraulic drawn release type. The release bearing is in several parts and I can't even get that together. I have a feeling that the T.O. bearing goes between the flywheel and the pressure plate. I have never worked on a Porsche and I've never even seen one together before, so I need some help getting started. Pictures would be helpful.

Pictures of what I have attached, thanks.

Oh I forgot. Once you have the lock tab removed from the T.O. bearing fork shaft how do you get it out so that the fork can be installed. I didn't want to start pounding on things so I though I should ask first.

Pictures of what I have attached, thanks.

Oh I forgot. Once you have the lock tab removed from the T.O. bearing fork shaft how do you get it out so that the fork can be installed. I didn't want to start pounding on things so I though I should ask first.

Attachments

-

HPIM0626.jpg210.3 KB · Views: 562

HPIM0626.jpg210.3 KB · Views: 562 -

HPIM0627.jpg129.2 KB · Views: 423

HPIM0627.jpg129.2 KB · Views: 423 -

HPIM0628.jpg212.2 KB · Views: 439

HPIM0628.jpg212.2 KB · Views: 439 -

HPIM0629.jpg227 KB · Views: 496

HPIM0629.jpg227 KB · Views: 496 -

HPIM0631.jpg109.3 KB · Views: 485

HPIM0631.jpg109.3 KB · Views: 485 -

HPIM0632.jpg115.5 KB · Views: 484

HPIM0632.jpg115.5 KB · Views: 484 -

HPIM0630.jpg211.1 KB · Views: 473

HPIM0630.jpg211.1 KB · Views: 473 -

HPIM0633.jpg116.4 KB · Views: 449

HPIM0633.jpg116.4 KB · Views: 449 -

HPIM0634.jpg152.7 KB · Views: 754

HPIM0634.jpg152.7 KB · Views: 754 -

HPIM0635.jpg227.8 KB · Views: 590

HPIM0635.jpg227.8 KB · Views: 590

Last edited: