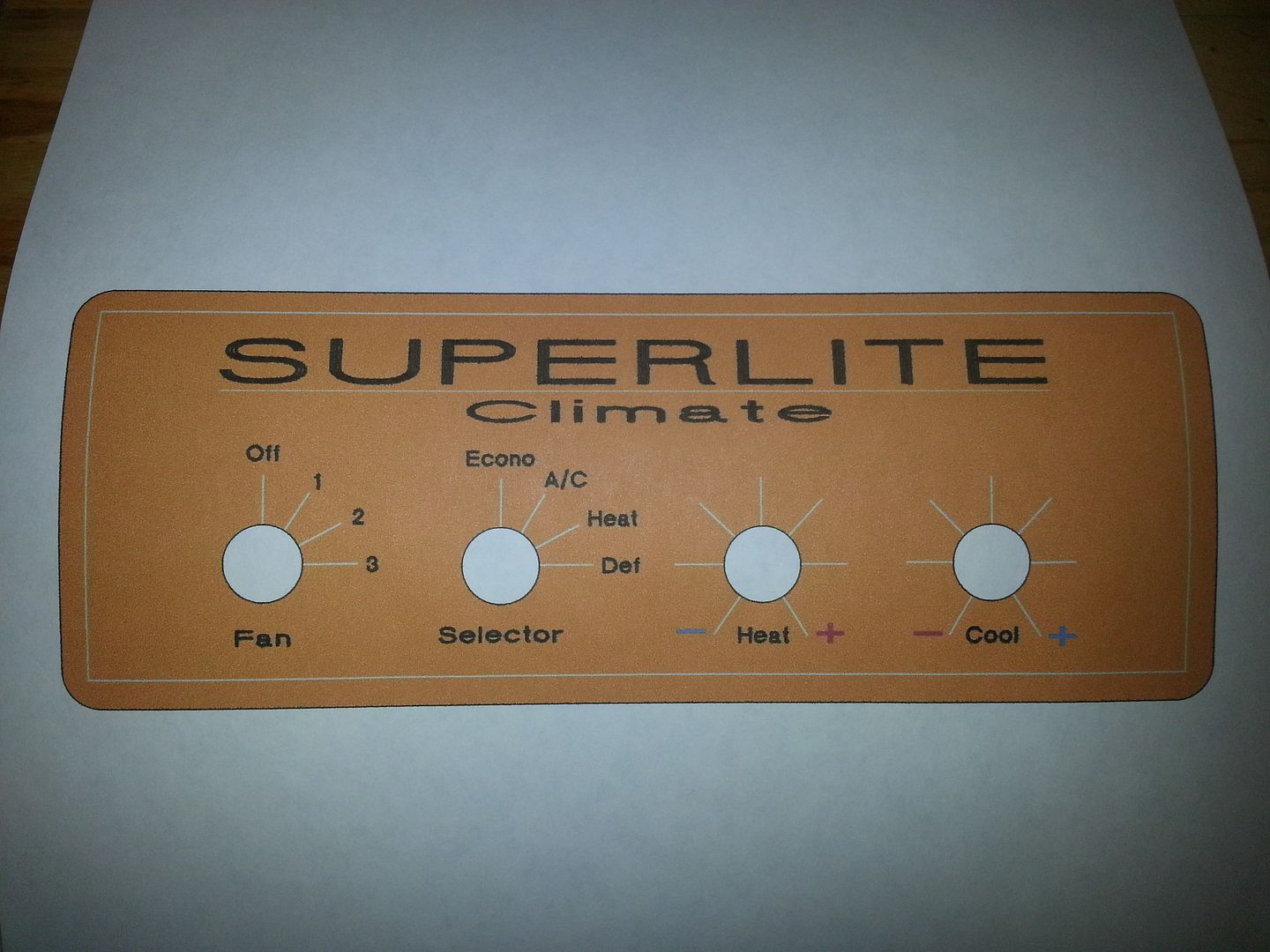

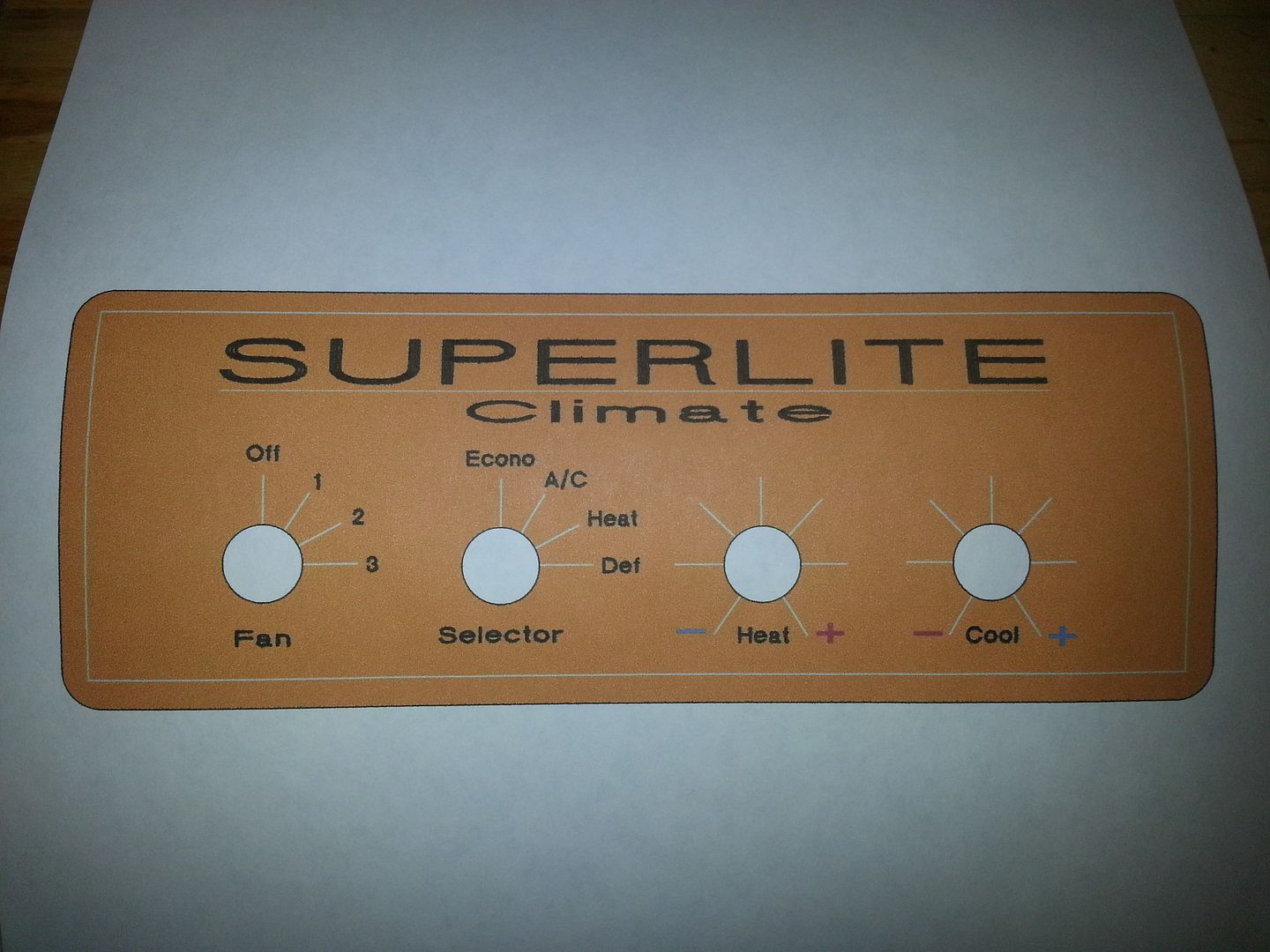

Thanks for Pete posting up about that front panel express place. This may be my new heater plate! CCan't believe you can have this made for $81! Took awhile to do, but well worth it.

This is just a print out of it. Scale is 7.5"wX2.5"h. Background is gold anodized ( I will have quite a bit of gold anodized throughout car) and everything white is raw alum details. It is parts like this that really finish a car off well. Glad Pete posted it, it may have created a monster here! Everything getting labeled!

Need to call Vintage and make sure I really need 4 rotary switches and that my layout and functions are correct.

This is just a print out of it. Scale is 7.5"wX2.5"h. Background is gold anodized ( I will have quite a bit of gold anodized throughout car) and everything white is raw alum details. It is parts like this that really finish a car off well. Glad Pete posted it, it may have created a monster here! Everything getting labeled!

Need to call Vintage and make sure I really need 4 rotary switches and that my layout and functions are correct.