what size is the clutch master cylinder in early CAV cars. My slave is crapping out and I want to match a new one with the master to ease up the pedal pressure. chuck

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

slave cylinder

- Thread starter chuck 1

- Start date

What gearbox?

ZF/rbt

Chuck can you post a picture either here or E mail me at [email protected]. There are at least 2 different possibilities for the slave.

Dave

Dave

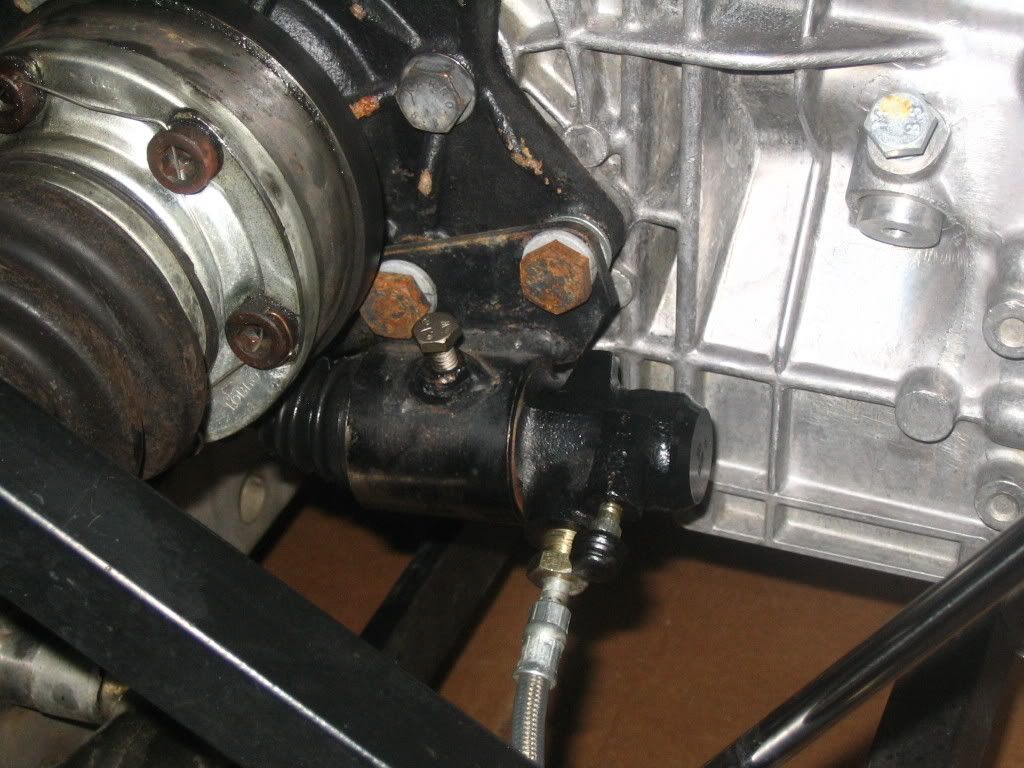

That is a slave of an audi 100.

Their were 2 types one with the groove and one without.

If someone has the part # for that slave It would be handy.

Jim

Their were 2 types one with the groove and one without.

If someone has the part # for that slave It would be handy.

Jim

this is a nice set up

Chuck if you will notice that the bracket in the previous reply has been extended to lower the slave cylinder and give it a better angle to push the clutch actuator, the stock CAV bracket forces the slave cylinder to pop the arm over center, greatly increasing the force required and causing a premature failure of the slave cylinder seals.

If you modify the bracket(for the slave) and move the pivot point(for the master cyl on the clutch pedal)you will reduce the effort required and extend the llife of the slave cyl.

Dave

If you modify the bracket(for the slave) and move the pivot point(for the master cyl on the clutch pedal)you will reduce the effort required and extend the llife of the slave cyl.

Dave

thanks David, I will try a new bracket. On a side note, I just recieved the parts for emergency brakes for my car(they were not on it originally. Do you have any pics of how it is hooked up? There is a large u shaped bar with the connecting cables running through it and I have no idea where it goes.

thanks Bob, it looks like that thing just sits in mid air attached only to the for and aft cables. I am missing the handbrake cabla, I suppose I can have one fabbed.

No problem Chuck. Glad to help. Drop me an email if you need other parking brake pictures or measurements. However I will mention that Wilwood has some very small light weight parking brake calipers that can be adapted and are much lighter than the stock CAV units.

Hi Chuck,

If you find the clutch effort remains high after changing the slave, you may want to look at pedal ratios, there's a modification for that as the Ford clutch pack is harder to lift than an Audi spec unit.

Basically it involves dropping the mounting height of the clutch master so you increase the pedal ratio with a minor increase in pedal stroke. A new hole is required in the clutch pedal too for the push rod clevis. I can send you the dimensions.

Also it's worth checking to make sure the bellhousing was "dialed in" using offset dowel pins during initial assembly. This is standard practice when using a non OEM bellhousing although it's a step easily missed.

The resulting, even slight misaligment in the input shaft and throwout bearing will bind the bearing on the sleeve it slides on and you'll need Superman legs to drop the clutch.

You might be able to see the slotted or hex keyed heads of the offset dowel pins through the bellhousing casting where it meets the block.

Cheers

If you find the clutch effort remains high after changing the slave, you may want to look at pedal ratios, there's a modification for that as the Ford clutch pack is harder to lift than an Audi spec unit.

Basically it involves dropping the mounting height of the clutch master so you increase the pedal ratio with a minor increase in pedal stroke. A new hole is required in the clutch pedal too for the push rod clevis. I can send you the dimensions.

Also it's worth checking to make sure the bellhousing was "dialed in" using offset dowel pins during initial assembly. This is standard practice when using a non OEM bellhousing although it's a step easily missed.

The resulting, even slight misaligment in the input shaft and throwout bearing will bind the bearing on the sleeve it slides on and you'll need Superman legs to drop the clutch.

You might be able to see the slotted or hex keyed heads of the offset dowel pins through the bellhousing casting where it meets the block.

Cheers

Attachments

Hi Chuck,

Also it's worth checking to make sure the bellhousing was "dialed in" using offset dowel pins during initial assembly. This is standard practice when using a non OEM bellhousing although it's a step easily missed.

You might be able to see the slotted or hex keyed heads of the offset dowel pins through the bellhousing casting where it meets the block.

Cheers

Really!!

Sounds like crap quality control and/or processes on the part of the bellhousing manufacturer.....

Sufficiently prevalent that someone has gone into production with offset dowells to correct poor manufacturing processes? And having to dial them in is accepted as standard practice!

Why not just build them right to start with? That's what we would do in NZ. Given that scenario and ethos, no wonder we sometimes have issues with overseas sourced parts......

I would always check a part, but I would be (am) highly pissed at having to do corrective surgery after I have paid good dollars for a faulty part! You guys accept it as the norm. No wonder you have problems!

Cheers

Last edited:

Hey Chuck,

Ian is right on with his recommendations, especially the cautions about the bell housing.

Also changing the mechanical advantage of the clutch pedal itself gave me much more precise control over the sweet spot when shifting. Here is a picture. I made two holes below the stock attachment point and moved the master cylinder back so the angular change of the push rod was minimized. The net result was slightly farther pedal travel, wider engage/disengage sweet spot, and less pedal pressure.

Ian is right on with his recommendations, especially the cautions about the bell housing.

Also changing the mechanical advantage of the clutch pedal itself gave me much more precise control over the sweet spot when shifting. Here is a picture. I made two holes below the stock attachment point and moved the master cylinder back so the angular change of the push rod was minimized. The net result was slightly farther pedal travel, wider engage/disengage sweet spot, and less pedal pressure.

Attachments

Russ, off set dowels were designed for use when using a hydroformed bell( SFI Lakewood for example) these are not machined and variances occur regularly. I agree a cast or machined part should fit perfectly,unfortunatly humans are making these parts and mistakes happen whether we like it or not. A wise man checks everything and makes adjustments where needed and refuses to use a vendor that does not do the same. Given NZ's lack of international presence in the automotive field (do you even produce a car for national consumption?) , it must be easy to say you would build them right in the first place, considering you do not build them to begin with. cheers. chuck

Chuck,

You're right of course on all counts.

Cheers

You're right of course on all counts.

Cheers

Similar threads

- Replies

- 7

- Views

- 277

- Replies

- 6

- Views

- 495

- Replies

- 0

- Views

- 180