Mike, no selection availableotherthan Lambo V10 as the taller ratios (extra cost) or Audi R8 for the standard ratio.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

slc Ls 376 and grazziano

- Thread starter silverback

- Start date

Fran,

Thank you! Mike

Thank you! Mike

V8 Gear ratios:

1st 4.373

2nd 2.709

3rd 1.878

4th 1.411

5th 1.126

6th 0.928

3.462 final

1st 4.373

2nd 2.709

3rd 1.878

4th 1.411

5th 1.126

6th 0.928

3.462 final

My current toy is 2000 S2000 w/ 9K redline 2 L. If i have done the math overall ratios are s2000; 1st 14.936, 6th 3.858; Grazziano; 1st 15.14, 6th 3.21. Honda will have lower effective gearing due to smaller wheel and tire but still that Grazzy 1st looks like a stump puller w/ 5-6 L twisting it!

Hey Dave, the pilot bearing goes in the flywheel with the graziano setup, not the crank. Would hate to see a $10k trans wrecked from a silly mistake.One thing that just occurred to me: The crate engine came via RCR with the pilot bearing already installed. I didn't check to see whether or not it was installed with loctite or if it is even required? Does anyone know if the pilot bearings need to be installed with loctite?

Dave Forster

Supporter

Oh, boy.

Maybe I did make a silly mistake?

If you look at picture #2 from post #85, you can see the pilot bearing installed in the end of the crank. The flywheel fits over the end of the crank and has a larger inside diameter. You can see it in picture #3.

If the pilot bearing is supposed to be installed in the flywheel, then that would mean that the bearing already installed in the end of my crank is an additional bearing, or is the wrong size and installed in the wrong place.

Can someone clarify this for me?

Thanks.

Maybe I did make a silly mistake?

If you look at picture #2 from post #85, you can see the pilot bearing installed in the end of the crank. The flywheel fits over the end of the crank and has a larger inside diameter. You can see it in picture #3.

If the pilot bearing is supposed to be installed in the flywheel, then that would mean that the bearing already installed in the end of my crank is an additional bearing, or is the wrong size and installed in the wrong place.

Can someone clarify this for me?

Thanks.

The bearing in the engine is stock from GM...nothing to do with the Graziano...the Graz. specific bearing installs in the flywheel as mentioned above...same technniqued used with the Ricardo...sorry for the confusion

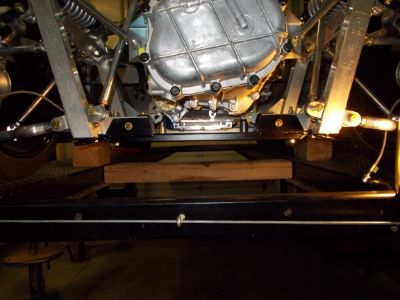

Dave , please remind me is your engine the LS7/...if so that's the reason your brackets and spacer are different than Millers, ...the factory oil cooler mounted on the LS7 dictates the need for them, whereas the LS3 does not have this cooler and can have the engine mounted without a spacer...

Dave , please remind me is your engine the LS7/...if so that's the reason your brackets and spacer are different than Millers, ...the factory oil cooler mounted on the LS7 dictates the need for them, whereas the LS3 does not have this cooler and can have the engine mounted without a spacer...

Dave Forster

Supporter

I'm glad to find this out now and not after starting the engine!

Yes, I have the LS7 engine.

Should the stock bearing in the end of the crank be removed or does it serve some other purpose that I would want to keep it there?

Now that the flywheel is already mounted on the engine, can the pilot bearing be tapped in with a hammer and block of wood, or will I need to remove the flywheel (and install new arp flywheel bolts?) to use an arbor press?

I can't edit my original post. If someone has that ability, perhaps they could remove my earlier comments on how to install the pilot bearing - I'd hate for someone else to do the same thing if they didn't read this thread through to here.

Dave

Yes, I have the LS7 engine.

Should the stock bearing in the end of the crank be removed or does it serve some other purpose that I would want to keep it there?

Now that the flywheel is already mounted on the engine, can the pilot bearing be tapped in with a hammer and block of wood, or will I need to remove the flywheel (and install new arp flywheel bolts?) to use an arbor press?

I can't edit my original post. If someone has that ability, perhaps they could remove my earlier comments on how to install the pilot bearing - I'd hate for someone else to do the same thing if they didn't read this thread through to here.

Dave

Last edited:

The bearing can be installed in the flywheel after the fact....

In good faith I would pull the original bearing even though it may never come out or become an issue.

In good faith I would pull the original bearing even though it may never come out or become an issue.

If it's like the Ricardo you want to press the bearing into the transaxle side (ask Bob what happens if you press it into the engine side, heh :/ ) of the flywheel 60-80 thousands below the surface .... I sure wouldn't want to sit there beating it into place with a block and wood and a hammer, but then again, you've got people here who have no problem sawing up their chassis so ymmv based on skill and confidence

Leave the bearing in the crankshaft, nothing will touch it so it's not even going to spin. Get a new bearing, toss it in the freezer, then warm the flywheel with a propane/mapp torch to ~150F. Bearing should almost fall in with a few taps from a dead blow.

With everything back together I decided to place the shifter in the car. It was then I realized that I hadn't cut the whole In the firewall for the cables to run threw the tube in the fuel tank into the engine compartment. It didn't take a super long time but I had to pull the seats , I had made my side impact bars connect to the front roll bar which I ran to the floor and side braced then with several braces to the floor and then the back. I was glad I made the drivers side removable incase I ever had to remove the fuel tank. I took It all apart trimmed for the cables cut a hole for access to the fuel sender and an access hole for the fuel pumps. I then re-installed everything ran the cables and called It a day. I have a question for Dave or anyone who has there cables hooked up to there grazziano. The cables just are threaded on the ends I am sure I can attach a hiem joint to them but the grazziano appears to have some strange hardware attaching points and I wonder what anybody else has come up with........suggestion's ?

Mahlon,

I will quiz Jim the cable supplier as to why they have no ends...

I will quiz Jim the cable supplier as to why they have no ends...

Dave Forster

Supporter

Mahlon,

You are ahead of me on this. I have not tried to connect the cables yet, but will be watching to see what you find as you blaze the trail!

You are ahead of me on this. I have not tried to connect the cables yet, but will be watching to see what you find as you blaze the trail!

Has the cable ends been resolved? I too have a graziano transaxle. This thread has been very informed. Please provide pictures of end product. Thanks

Similar threads

- Replies

- 27

- Views

- 13K

- Replies

- 0

- Views

- 22K