Since I wasn't around when the trans was first installed to the motor, I am having a time getting all together. I have searched and read most of the postings from Ron's delima installing his to the rubber band tricks for installing the TO bearing. Most are for the G50, some for the 930.

It appears that the TO bearing sits inside the pressure plate. We marked the pieces so they would match up as they were when we took it apart for the engine inspection when metal was found in one of the spark plugs(another post later). The pressure plate and clutch all line up well. Using a clutch installation tool, it falls into place. I don't remember how the TO bearing was mounted when we separated the parts. What I need to know is, is my TO bearing the correct piece and does it mount inside the pressure plate, and are any pieces of it missing. All the pics I find show something a little different. It may be these are for a G50. Moelleur(sp?) posted a pic on his setup when he sold it and the TO looks like mine. So here is what I have and a little help from you guys would be nice.

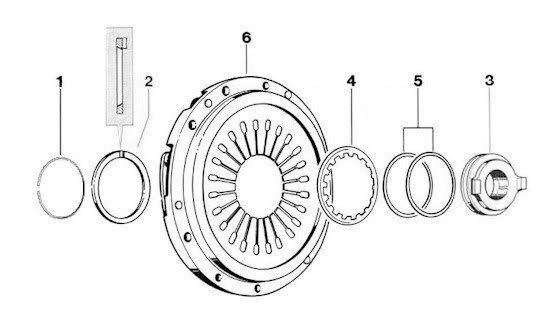

Here is the TO bearing.

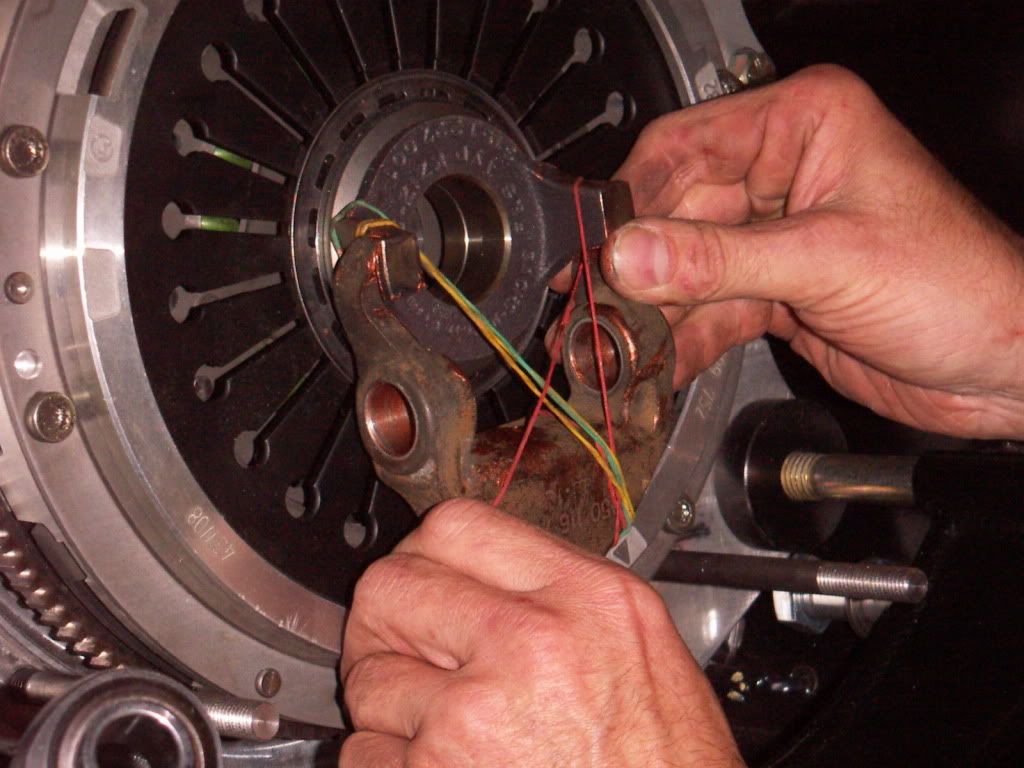

Here is the pressure plate/flywheel setup.

From what I can make out the clutch is a pull arrangement. The fingers of the PP go in toward the flywheel. Lining it up for the mating is easy enough to do based on postings using the rubber bands. Even though they are for a G50, I can see how it works here.

Is there anything I am missing out on?

I am also in the middle of selecting the proper master cylinder. I have a 996 slave and I don't know its area, so I am using the try it method with master cylinders. I am down to a 5/8" unit now since the 3/4 and 1" wouldn't budge it.

Bill

It appears that the TO bearing sits inside the pressure plate. We marked the pieces so they would match up as they were when we took it apart for the engine inspection when metal was found in one of the spark plugs(another post later). The pressure plate and clutch all line up well. Using a clutch installation tool, it falls into place. I don't remember how the TO bearing was mounted when we separated the parts. What I need to know is, is my TO bearing the correct piece and does it mount inside the pressure plate, and are any pieces of it missing. All the pics I find show something a little different. It may be these are for a G50. Moelleur(sp?) posted a pic on his setup when he sold it and the TO looks like mine. So here is what I have and a little help from you guys would be nice.

Here is the TO bearing.

Here is the pressure plate/flywheel setup.

From what I can make out the clutch is a pull arrangement. The fingers of the PP go in toward the flywheel. Lining it up for the mating is easy enough to do based on postings using the rubber bands. Even though they are for a G50, I can see how it works here.

Is there anything I am missing out on?

I am also in the middle of selecting the proper master cylinder. I have a 996 slave and I don't know its area, so I am using the try it method with master cylinders. I am down to a 5/8" unit now since the 3/4 and 1" wouldn't budge it.

Bill