Hi

i´m thinking about installing an ACCUSUMP into my car.

Idee is to build a pretty simple system which helps to add security in hard cornering. I have a AVIAD GT40 oilpan do you recommand an ACCUSUMP with this anyway ?

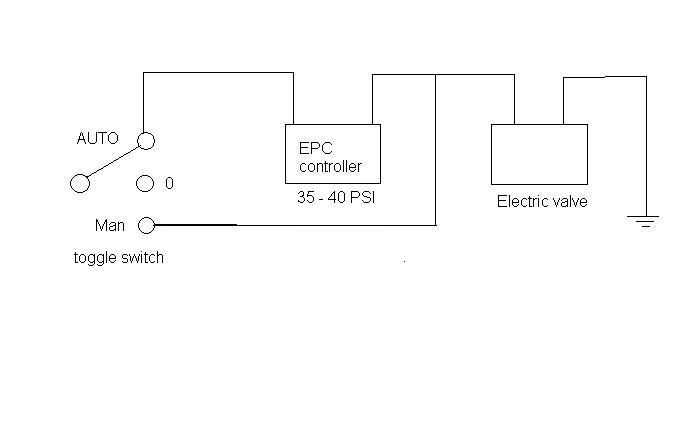

I intend to put in a electrical valve which i switch on when i plan to run the car a little harder. Thus having the ACCUSUMP than permanently open to balance out any pressure drops and get refeeded when pressure rises again.

Is this the correct way to use and install it ?

My thoughts are to tie it into the return line from the oil cooler with a T- fitting. Do i need a check valve which prevent the oil flowing back wards in direction to the oil pump?

What size ACCUSUPM you recommand ?

Any sketches and experiences are very welcome.

Thanks

TOM

i´m thinking about installing an ACCUSUMP into my car.

Idee is to build a pretty simple system which helps to add security in hard cornering. I have a AVIAD GT40 oilpan do you recommand an ACCUSUMP with this anyway ?

I intend to put in a electrical valve which i switch on when i plan to run the car a little harder. Thus having the ACCUSUMP than permanently open to balance out any pressure drops and get refeeded when pressure rises again.

Is this the correct way to use and install it ?

My thoughts are to tie it into the return line from the oil cooler with a T- fitting. Do i need a check valve which prevent the oil flowing back wards in direction to the oil pump?

What size ACCUSUPM you recommand ?

Any sketches and experiences are very welcome.

Thanks

TOM