You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bakers Build

- Thread starter Keith Baker

- Start date

Keith, you are clearly NOT a newbie! I can't wait to see more photos of your awesome project.

/ubbthreads/images/graemlins/blush.gif /ubbthreads/images/graemlins/blush.gif /ubbthreads/images/graemlins/blush.gif /ubbthreads/images/graemlins/blush.gif simply no words.

This is what i mean MAKE GREAT CARS

u are great!

Paul

This is what i mean MAKE GREAT CARS

u are great!

Paul

Hi Dave

The Carbon panels are made from moulds which is not easy.

The moulds to date are 3mm steel polished and 2 pack painted, unfortunatly the curing heat process makes the Carbon shrink at different rates to the metal, so some carbon parts have distorted . failure rate is about 50% but what is left of the best of the larger panels can be used in areas where flat sheet is required so loss is not so bad

Each sheet is aprox 3 mm thick so its like a sheet of concrete with less wt than ally 1.5mm ( 16g ).

each panel is bonded and riveted so the whole thing is structural.

I am in the process of small ally moulds for small areas which when carbon is cured will destroy the ally, sort of disposable moulds.

I will add a few more pic's when I can. Good to here from you.

The engine going in the forty is the same spec as my ultima which is 600+ BHP Chevy, dry sumped, kinsler injection and motec management and it goes like s##t of a stick pictures will also follow in due course

Regards Keith

The Carbon panels are made from moulds which is not easy.

The moulds to date are 3mm steel polished and 2 pack painted, unfortunatly the curing heat process makes the Carbon shrink at different rates to the metal, so some carbon parts have distorted . failure rate is about 50% but what is left of the best of the larger panels can be used in areas where flat sheet is required so loss is not so bad

Each sheet is aprox 3 mm thick so its like a sheet of concrete with less wt than ally 1.5mm ( 16g ).

each panel is bonded and riveted so the whole thing is structural.

I am in the process of small ally moulds for small areas which when carbon is cured will destroy the ally, sort of disposable moulds.

I will add a few more pic's when I can. Good to here from you.

The engine going in the forty is the same spec as my ultima which is 600+ BHP Chevy, dry sumped, kinsler injection and motec management and it goes like s##t of a stick pictures will also follow in due course

Regards Keith

Pete McCluskey.

Lifetime Supporter

Hi Keith, from the comments everyone is making it must be impressive. Unfortunately for some reason your pics don't show on my computer. All that shows is a small square with a red x in it??

Pete McCluskey.

Lifetime Supporter

Yep, got them this time, everyone's comments are right on the money, it looks terrific. say thanks to your boy for me.

Scott McDill

Supporter

Keith,

Nice finish and color on the transaxle. Is it painted?

Nice finish and color on the transaxle. Is it painted?

BAKERS BUILD CONTINUED

Sorry for not answering any questions but I'm often very LAZY

The paint work on the gearbox is actually 2 pack paint on etch primer.

But after looking at it I may change this to a lighter shade, although it looks good against polished ally of the adaptor plate and other items.

The car will probably be in a mustard shade of yellow, this with the black of the Carbon will look the dogs.

carbon fibre work another shot

and another - click the link

http://i13.photobucket.com/albums/a262/bakergt40/gt023.jpg

Sorry for not answering any questions but I'm often very LAZY

The paint work on the gearbox is actually 2 pack paint on etch primer.

But after looking at it I may change this to a lighter shade, although it looks good against polished ally of the adaptor plate and other items.

The car will probably be in a mustard shade of yellow, this with the black of the Carbon will look the dogs.

carbon fibre work another shot

and another - click the link

http://i13.photobucket.com/albums/a262/bakergt40/gt023.jpg

Hi all, Just an update of my GTD build in the UK, Attached is some pictures of it's progress.

As some of you know there's only a few builds going on with GTD chassis's now days but these chassis and bodys are now available through Roy Smart mine being the second, Brett Mcall being the first.As you can see the body from lee Dawson (Ex.GTD ) fits well with only minimal fettling to do.The Carbon panelling is coming on but at a slower rate than I would like.

patients is what's needed when aligning the body

Only cut away enough to clear in the early stages of alignment as you cant put it back easily

Getting there slowly

Pre fitting of the dashboard, cutting the edges away to clear the Full cage

More updates as and when.

As some of you know there's only a few builds going on with GTD chassis's now days but these chassis and bodys are now available through Roy Smart mine being the second, Brett Mcall being the first.As you can see the body from lee Dawson (Ex.GTD ) fits well with only minimal fettling to do.The Carbon panelling is coming on but at a slower rate than I would like.

patients is what's needed when aligning the body

Only cut away enough to clear in the early stages of alignment as you cant put it back easily

Getting there slowly

Pre fitting of the dashboard, cutting the edges away to clear the Full cage

More updates as and when.

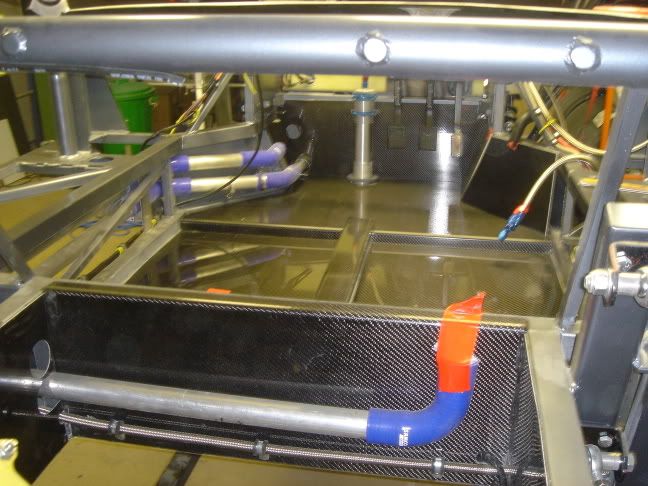

Two updated pictures of the Carbon Fibre interior.

The sill panels have been made from moulds so as to get a perfect 7mm radius, snug fitting the chassis rails. The dashboard has been covered in black leather with carbon facia panels moulded in.

The interior panels still need some rivets but being bonded as well gives superior strength and rigidity.

The front inner wheel arches are also being made in carbon / ally but because of the many angles it's a bit of a job . Each panel is taking at least one evening of about 4-5 hours and there are 5 panels under each front wheel arch.

The gear change rod assy is now made from stainless steel and is at the welders ( I can't weld stainless or ally )Pictures to follow of the G50 rod system.

More pictures as and when

http://i13.photobucket.com/albums/a262/bakergt40/carboninteriormarch0612.jpg

http://i13.photobucket.com/albums/a262/bakergt40/carboninteriormarch0611.jpg

The sill panels have been made from moulds so as to get a perfect 7mm radius, snug fitting the chassis rails. The dashboard has been covered in black leather with carbon facia panels moulded in.

The interior panels still need some rivets but being bonded as well gives superior strength and rigidity.

The front inner wheel arches are also being made in carbon / ally but because of the many angles it's a bit of a job . Each panel is taking at least one evening of about 4-5 hours and there are 5 panels under each front wheel arch.

The gear change rod assy is now made from stainless steel and is at the welders ( I can't weld stainless or ally )Pictures to follow of the G50 rod system.

More pictures as and when

http://i13.photobucket.com/albums/a262/bakergt40/carboninteriormarch0612.jpg

http://i13.photobucket.com/albums/a262/bakergt40/carboninteriormarch0611.jpg

Similar threads

- Replies

- 8

- Views

- 2K

- Replies

- 16

- Views

- 7K